Hydrophilic polyurethane, hydrophilic polyurethane foaming body and made wet-type wound dressing

A hydrophilic polyurethane and foam technology, which is applied in the field of polyurethane, can solve the problems of limited wound healing, reduced absorption effect, loss of active ingredients and replacement of dressings, etc., and achieves the effect of promoting wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Star-shaped hydrophilic polyurethane PU1

[0027] Mix 1 mol of PPG6000triol (weight average molecular weight of 6,000) with 3 mol of HDI, react at 80°C for 1 hour to obtain a star-shaped prepolymer, then add 1 mol of PEG1000 (weight average molecular weight of 1,000), 1.5 mol of PEG2000 (weight average molecular weight of 2,000) and 0.5 mol of hyaluronic acid (weight average molecular weight 1,000,000), carry out cross-linking reaction at 80°C for 6 hours to obtain star-shaped hydrophilic polyurethane PU1.

Embodiment 2

[0028] Star-shaped hydrophilic polyurethane PU2

[0029] Mix 0.5mol PPG6000triol with 2.5mol HDI, react at 80°C for 1 hour to obtain a star-shaped prepolymer, then add 0.85mol PEG1000, 0.85mol PEG2000 and 0.1mol hyaluronic acid (weight average molecular weight: 1,000,000), at 80 The crosslinking reaction was carried out at ℃ for 6 hours to obtain star-shaped hydrophilic polyurethane PU2.

[0030] Wet wound dressing DR1

[0031] refer to figure 1 , the star-shaped hydrophilic polyurethane PU1 of Example 1 is mixed and stirred with 1mol HDI and coated on the release film, and heated at 120°C for 1 hour to obtain the following: figure 1 The sheet-shaped absorbent layer 1 is the wet wound dressing DR1.

[0032] Wet wound dressing DR2

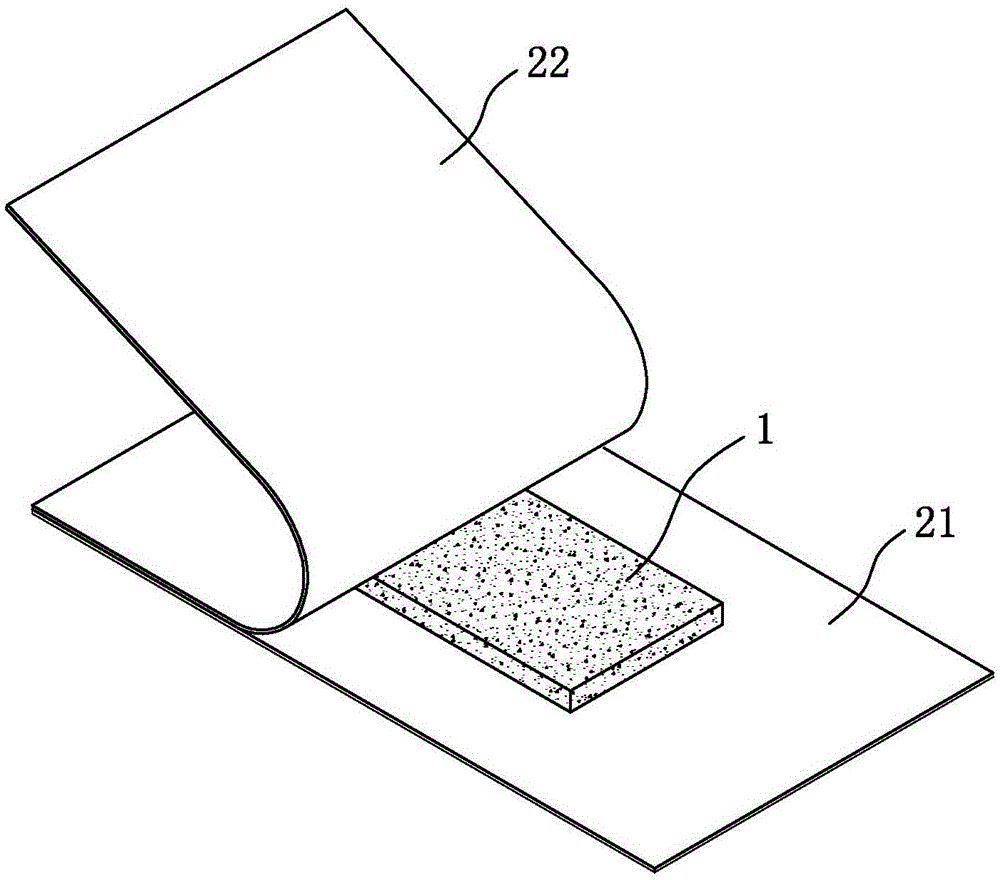

[0033] refer to figure 1 and figure 2 , 0.1mol sodium bicarbonate (foaming agent), 0.4mol water, 0.5mol polydimethylsiloxane-polyoxyalkylene copolymer (surfactant), 0.1mol ethylenediamine and 0.1mol zinc isooctanoate (catalyst , purchased f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com