Preparation method of Fenton-like catalyst, as well as product and application of Fenton-like catalyst

A catalyst, Fenton's technology, applied in the field of preparation of Fenton-like catalysts, can solve the problems of limited reaction conditions, low reusability of catalyst recovery, iron ion residues, etc., to solve the problem of narrow pH range, rapid and effective degradation, and solution hard to recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

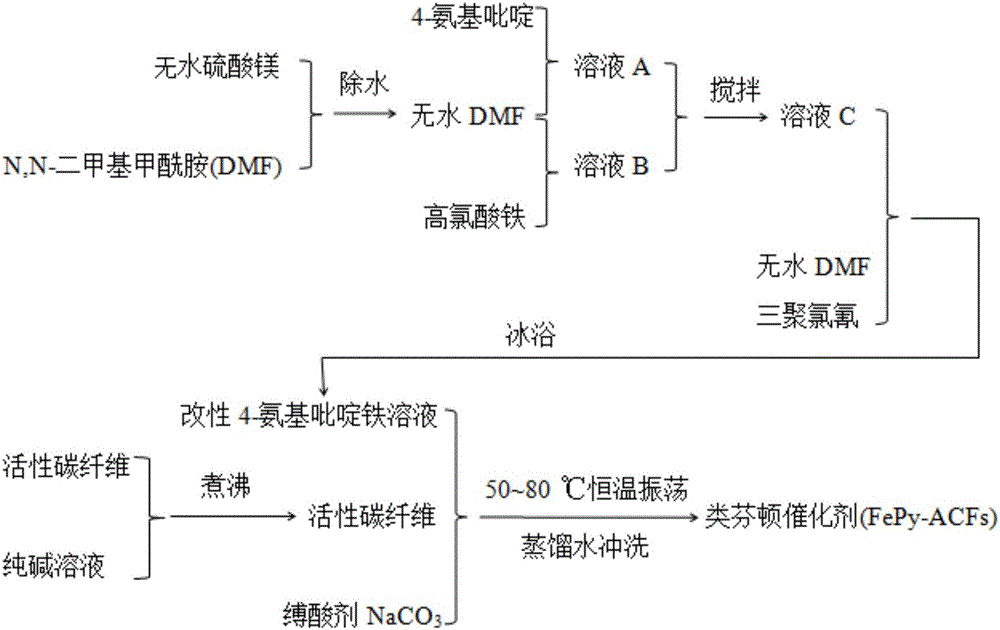

[0023] Such as figure 1 Shown, the present invention provides a kind of preparation method of Fenton-like catalyst, take 4-aminopyridine and ferric perchlorate as reaction precursor, react in anhydrous N,N-dimethylformamide solution to obtain 4-aminopyridine Iron, and then bond 4-aminopyridine iron on the activated carbon fiber to obtain a Fenton-like catalyst.

[0024] Specifically include the following steps:

[0025] Step 1, the pretreatment of activated carbon fiber;

[0026] Take some activated carbon fibers, put them in a beaker, add soda ash Na 2 CO 3 Boil in the solution for 30-60 minutes, take out the activated carbon fiber, rinse it, dry it in an oven at 60-80 degrees, and set it aside for use, in which the soda ash Na 2 CO 3 The concentration of the solution is 3-6g / L, activated carbon fiber and soda ash Na 2 CO 3 The mass ratio is 1:10-15.

[0027] Step 2, preparing anhydrous N,N-dimethylformamide DMF;

Embodiment

[0038] As an embodiment of the present invention, get activated carbon fiber 4g, add 50mL soda ash Na 2 CO 3 In solution, Na 2 CO 3 The solution concentration is 4g / L, boiled for 30min, rinsed and dried in an oven at 70°C; take 150mL of anhydrous DMF, add 3g of 4-aminopyridine, and slowly add ferric perchlorate anhydrous DMF solution to it under stirring conditions 50mL, the quality of ferric perchlorate is 2g, until a brownish-red liquid is formed; then add 50mL of anhydrous DMF solution of cyanuric chloride to the brownish-red liquid, the quality of cyanuric chloride is 6g, react in an ice bath for 4h, Obtain modified 4-aminopyridine iron solution; then add Na to the modified 4-aminopyridine iron solution 2 CO 3 4g of the treated activated carbon fiber was shaken and reacted in a constant temperature oscillator at 60°C for 10h, then washed with distilled water, and dried in an oven at 60°C to obtain FePy-ACFs. Take 2g of FePy-ACFs, put it in 100mL, 200mg / L methyl orange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com