Tubeless steel wheel provided with non-welded rim part with non-uniform thickness as well as processing technology of wheel

A technology without welding and inner tube steel, which is applied in the field of wheels, can solve the problems of sparks, dust, cumbersome process of tubeless steel wheels, and harsh welding production environment in the production process, so as to achieve good overall surface quality, good air tightness, The effect of streamlining management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

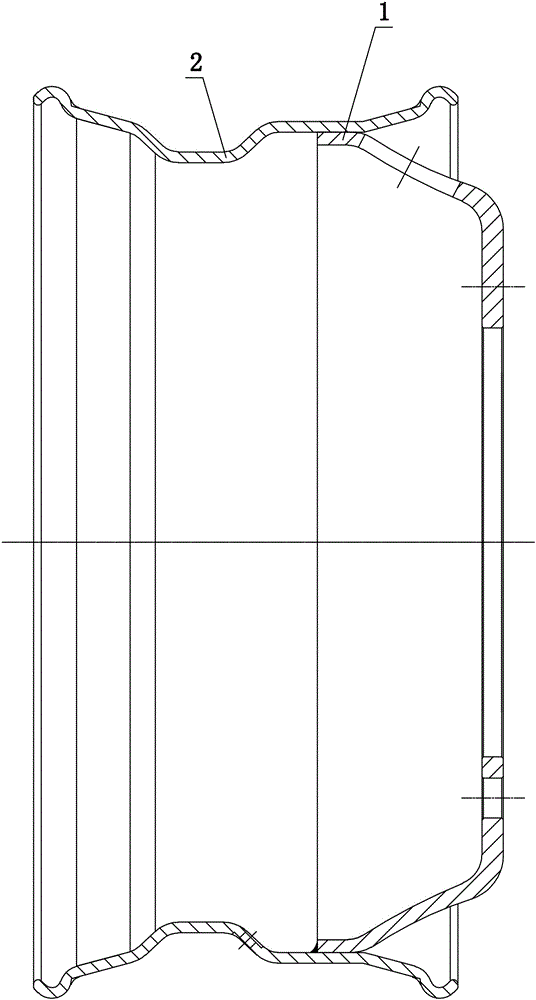

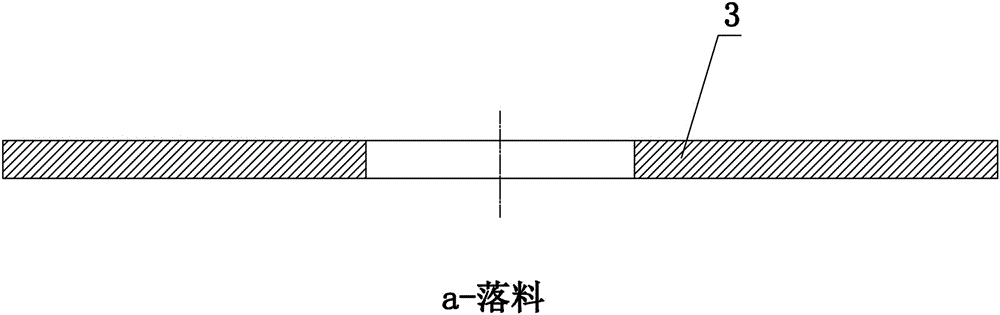

[0018] refer to figure 1 . A tubeless steel wheel with no welding and unequal thickness on the rim, comprising a spoke 1 and a rim 2, the spoke 1 and the rim 2 are made of the same round cake material 3, which is spun twice The spoke raw material 4 and the rim raw material 5 are formed by circular cutting, and the spoke raw material 4 and the rim raw material 5 are formed into the spoke 1 and the rim 2 after repeated spinning, and the spoke 1 and the rim 2 are welded together by welding.

[0019] refer to Figure 2 to Figure 7 . A processing technology for a tubeless steel wheel with no welding and unequal thickness on the rim, comprising the following steps:

[0020] a. Blanking: drop out the whole round cake material 3 required for the tubeless steel wheel.

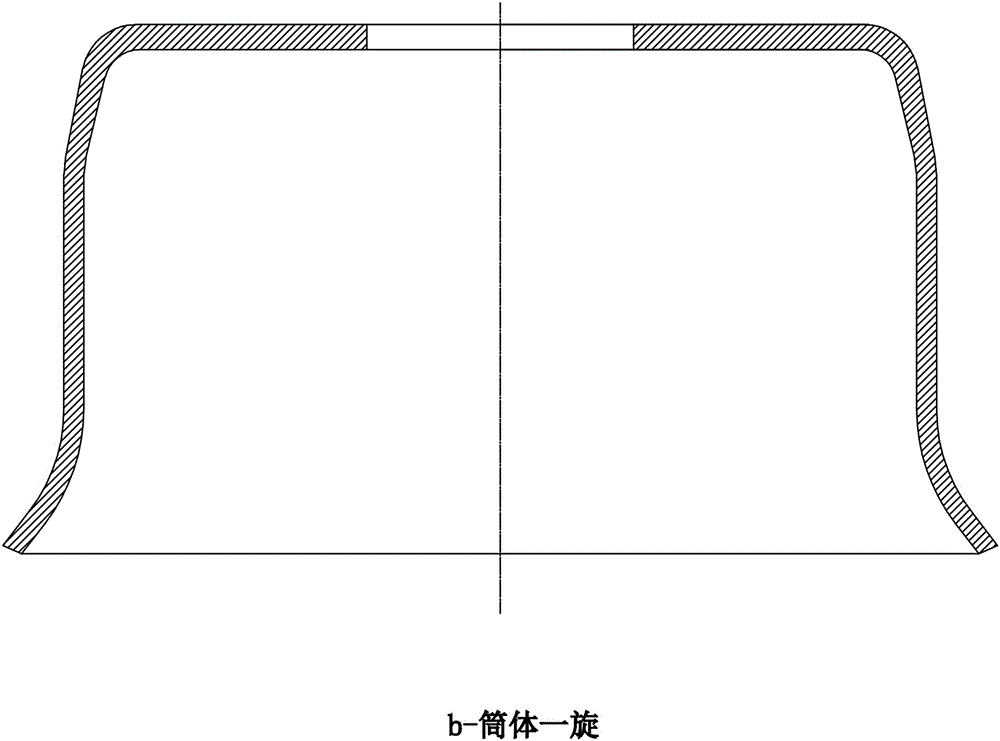

[0021] b. Cylinder first spinning: Spinning the round cake material 3 for the first time to deform its outer circle and form a cylinder, the thickness of which remains unchanged or slightly thinned.

[0022] c. Sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com