Process for purification of wet-process phosphoric acid

A wet-process phosphoric acid and purification process technology, applied in the direction of phosphorus compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of low phosphoric acid efficiency, high cost, complicated process, etc., and achieve maximum benefit, less entrained phosphoric acid, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

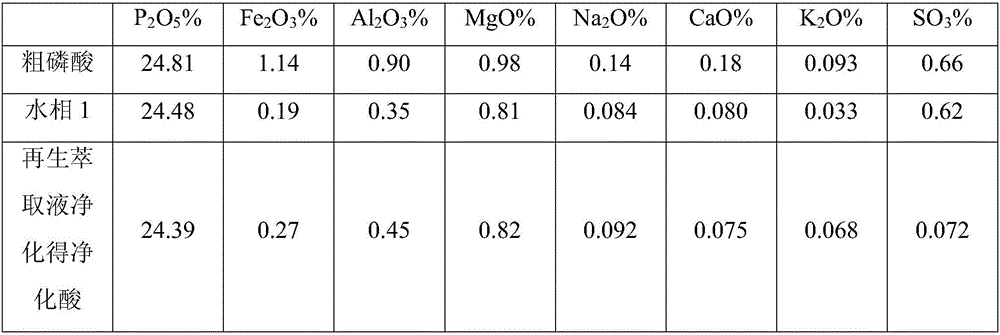

[0066] Low-grade phosphoric acid is used as raw material phosphoric acid, in which the content of iron, aluminum and magnesium ions is relatively high, and the indicators are shown in Attached Table 1.

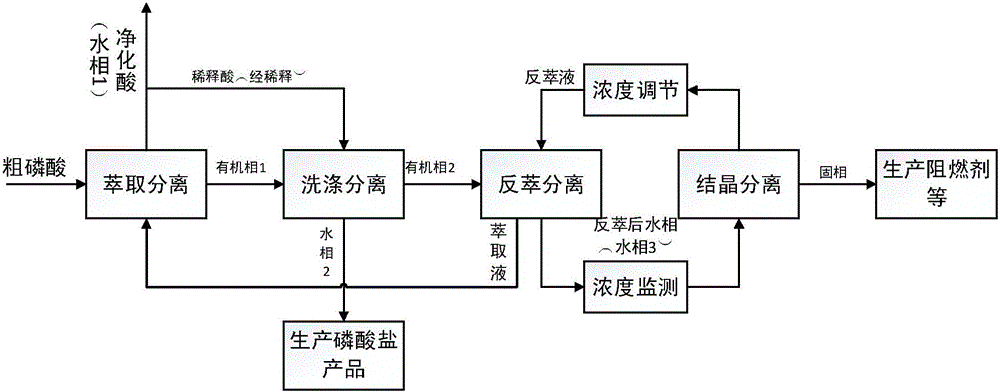

[0067] The wet phosphoric acid purification process includes the following steps:

[0068] (1) Extraction and separation of crude phosphoric acid: crude phosphoric acid and extract are mixed and extracted, the number of extractions is 3 times, the extraction ratio (volume ratio of extract: crude phosphoric acid) is 3:1, the extraction temperature is 60°C, the extraction time is 30 minutes, and the extraction time is 30 minutes. Phase 10min to get organic phase 1 (containing extractant) and water phase 1 (water phase 1 is purified phosphoric acid); the content of each substance in purified phosphoric acid is shown in attached table 1; the extract is P204 diluted with sulfonated kerosene, and the dilution ratio : 1 (i.e. the volume ratio of sulfonated kerosene and P204);

[006...

Embodiment 2

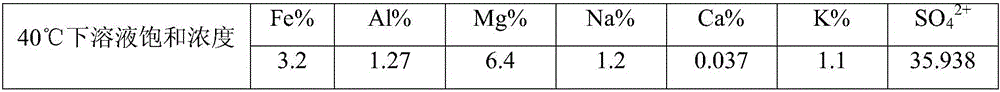

[0081] Experimental operating conditions and raw materials are the same as in Example 1. But back extraction regeneration uses the sulfuric acid that concentration is 20wt%, its each parameter sees attached table 3 and 4.

[0082] table 3

[0083]

[0084] Table 4

[0085]

Embodiment 3

[0087] Experimental operating conditions and raw materials are the same as in Example 1. However, the extract is DNNSA diluted with sulfonated kerosene, and the dilution ratio is 2:1 (that is, the volume ratio of sulfonated kerosene to P204), and its parameters are shown in attached tables 5 and 6.

[0088] table 5

[0089]

[0090] Table 6

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com