Optical glass kiln melting tank

An optical glass and melting pool technology, applied in furnaces, retort furnaces, furnace types, etc., can solve the problems of high energy consumption and high investment in fixed assets, and achieve the effects of reducing energy consumption, easy fixing, and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

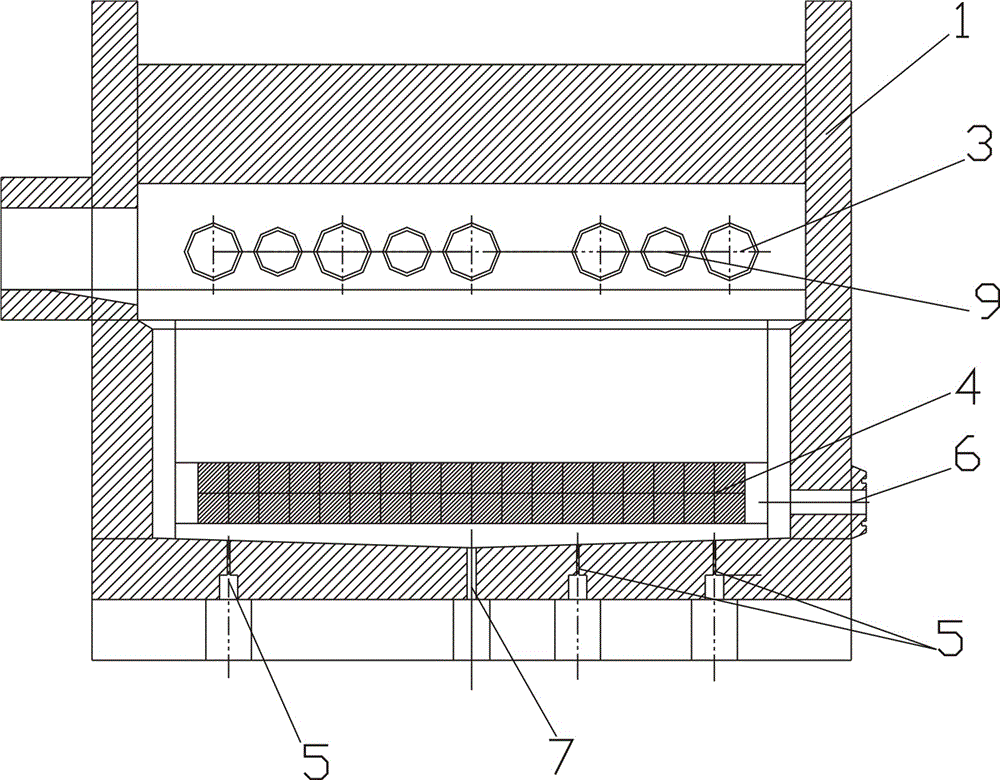

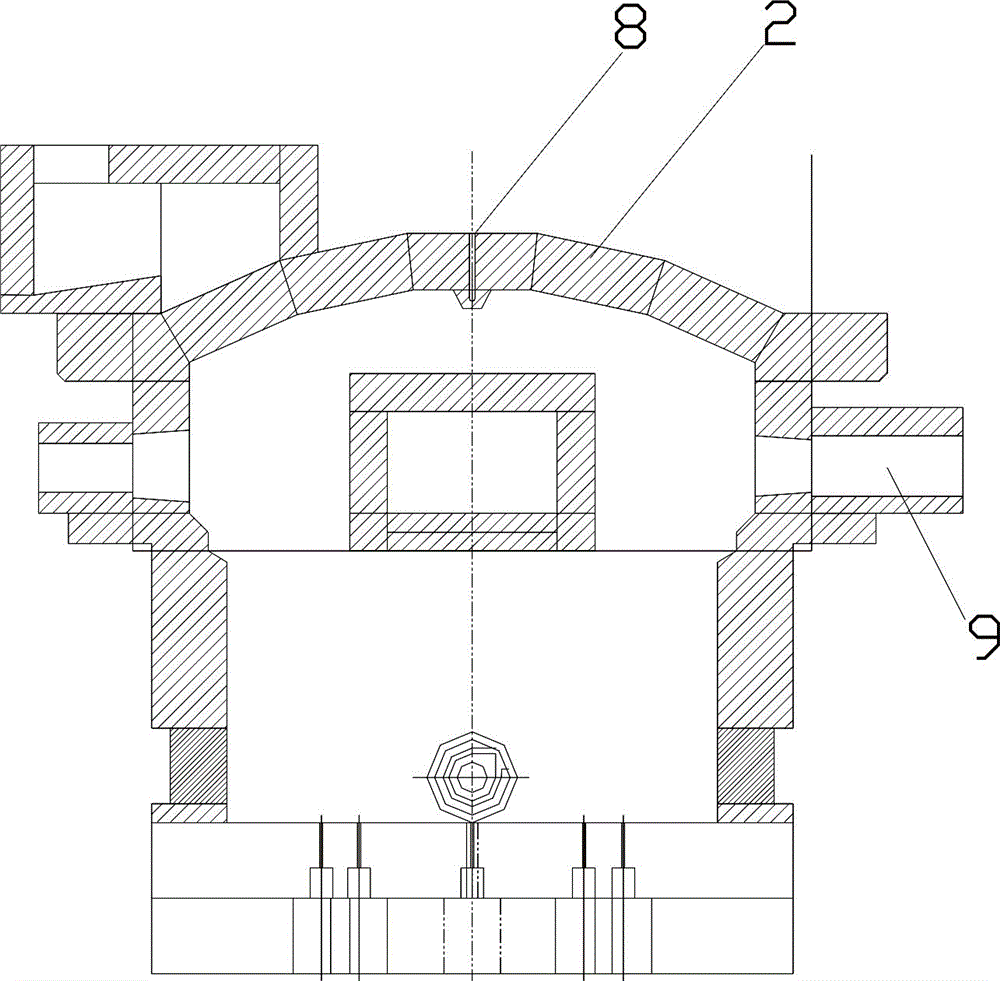

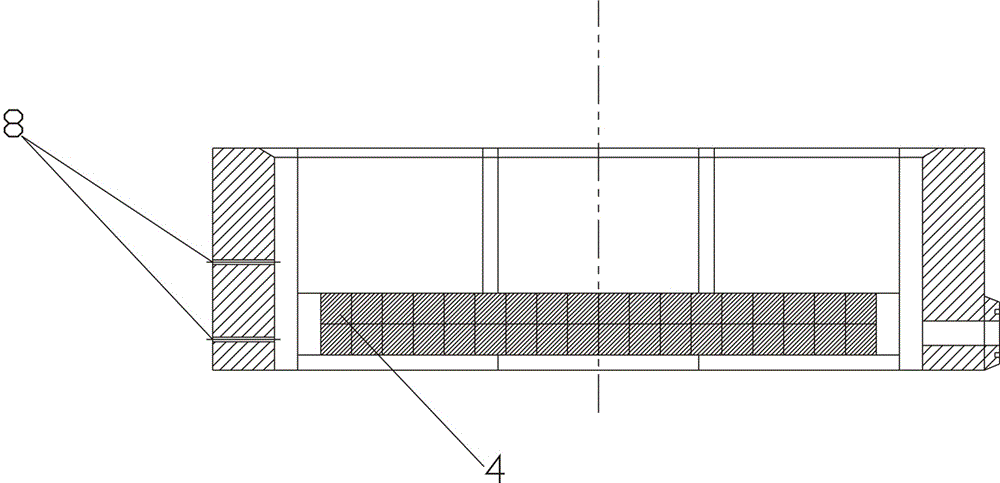

[0023] like Figure 1~Figure 3 As shown, a melting pool of an optical glass furnace includes a melting pool body 1 composed of wall bricks, and a top 2 is provided on the top of the melting pool body 1 . The main body of the melting pool is square, with an area of 1.92~6 square meters and a depth of 0.72~1.4 meters.

[0024] The upper part of the main body 1 of the melting tank is provided with 3 to 5 burners 3, which are mainly heated by liquefied gas or natural gas, and supplemented by electric heating. Natural gas heating is conducive to the increase of the temperature of the heating space; the tumbling of the bubbler is conducive to the heat exchange between the glass liquid and the natural gas heating space, and the glass temperature is increased without causing adverse effects on the quality of the glass; the electric heating is supplemented by the main solution near the bottom of the kiln. low temperature problem.

[0025] The side of the main body 1 of the melting ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap