High flame-retardant level halogen-free polycarbonate film material and preparation method thereof

A technology of polycarbonate and film materials, which is applied in the field of high flame-retardant halogen-free polycarbonate film materials and its preparation, and can solve the problems of easy generation of toxic and harmful corrosive gases, poor thermal resistance of polycarbonate films, and hazards Human health and other issues, achieving good light transmittance, high flame retardancy, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

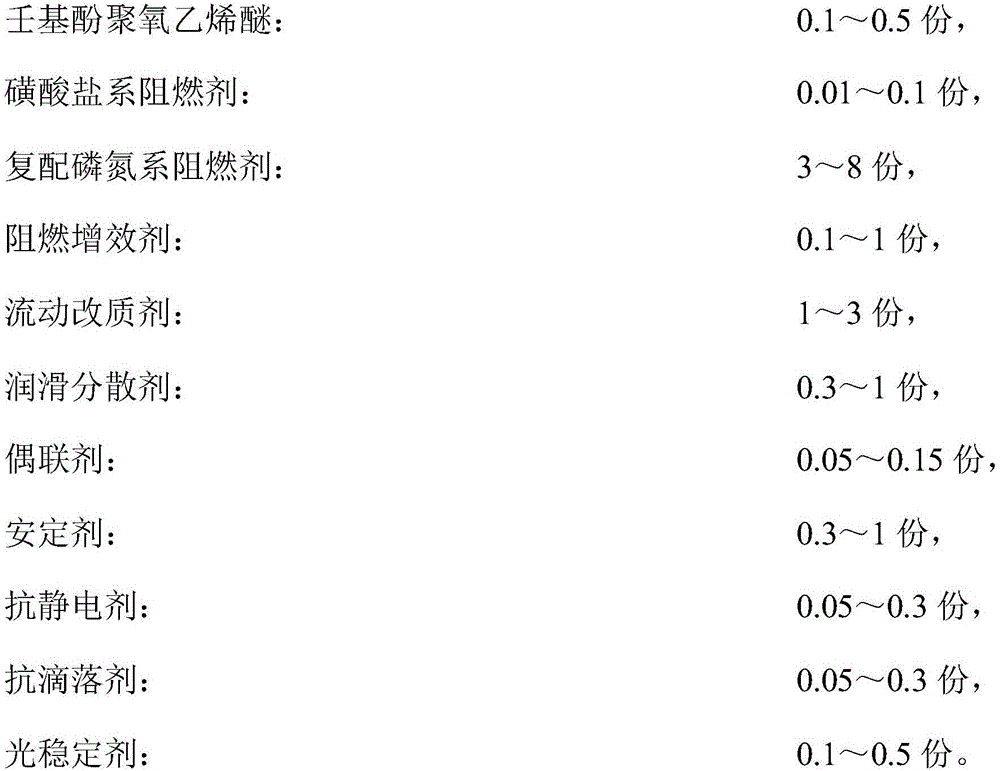

[0030] A high flame retardant grade halogen-free polycarbonate film material is made from the following raw materials by weight:

[0031]

[0032]

[0033] Among them, the polycarbonate resin is a combination of a viscosity average molecular weight of 18000-20000 and a viscosity average molecular weight of 28000-32000 polycarbonate resin, and the weight ratio of the two is 2:1; the sulfonate flame retardant is perfluorobutyl The combination of sulfonate and potassium 3-benzenesulfonylbenzenesulfonate, the weight ratio of the two is 1:1; the compound phosphorus-nitrogen flame retardant is the combination of aluminum dialkylphosphinate, melamine phosphate and phosphazene , the weight ratio of the three is 7:3:1; the flame retardant synergist is a combination of alumina and zinc phosphate, and the weight ratio of the two is 2:5; the flow modifier is turpentine, terpene resin, acrylic acid ethyl acetate The combination of ester and silicone resin, the weight ratio is 1:1:1:3...

Embodiment 2

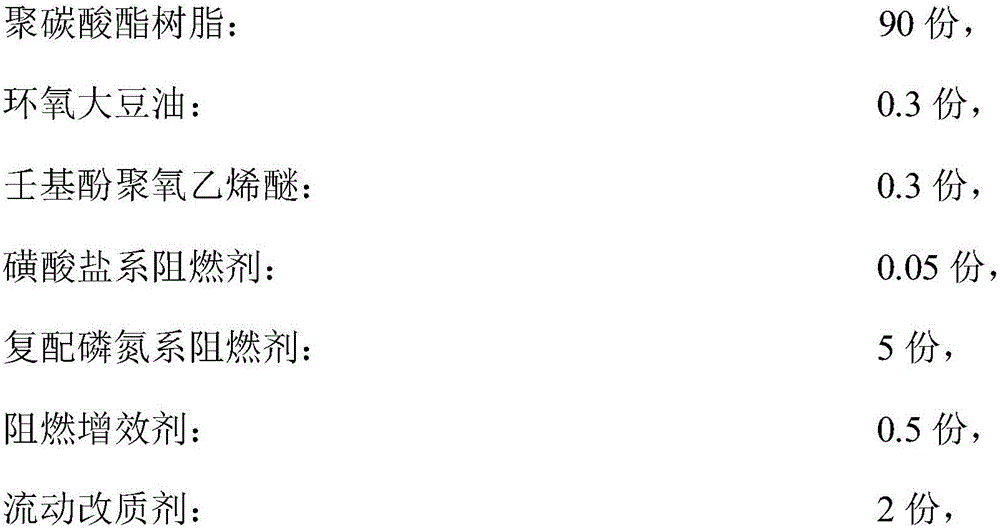

[0039] A high flame retardant grade halogen-free polycarbonate film material is made from the following raw materials by weight:

[0040]

[0041] Among them, the polycarbonate resin is a combination of a viscosity average molecular weight of 18000-20000 and a viscosity average molecular weight of 28000-32000 polycarbonate resin, and the weight ratio of the two is 2:1; the sulfonate flame retardant is perfluorobutyl The combination of sulfonate and potassium 3-benzenesulfonylbenzenesulfonate, the weight ratio of the two is 1:1; the compound phosphorus-nitrogen flame retardant is the combination of aluminum dialkylphosphinate, melamine phosphate and phosphazene , the weight ratio of the three is 7:3:1; the flame retardant synergist is a combination of alumina and zinc phosphate, and the weight ratio of the two is 2:5; the flow modifier is turpentine, terpene resin, acrylic acid ethyl acetate The combination of ester and silicone resin, the weight ratio is 1:1:1:3:2; the lubr...

Embodiment 3

[0047] A high flame retardant grade halogen-free polycarbonate film material is made from the following raw materials by weight:

[0048]

[0049]

[0050] Among them, the polycarbonate resin is a combination of a viscosity average molecular weight of 18000-20000 and a viscosity average molecular weight of 28000-32000 polycarbonate resin, and the weight ratio of the two is 2:1; the sulfonate flame retardant is perfluorobutyl The combination of sulfonate and potassium 3-benzenesulfonylbenzenesulfonate, the weight ratio of the two is 1:1; the compound phosphorus-nitrogen flame retardant is the combination of aluminum dialkylphosphinate, melamine phosphate and phosphazene , the weight ratio of the three is 7:3:1; the flame retardant synergist is a combination of alumina and zinc phosphate, and the weight ratio of the two is 2:5; the flow modifier is turpentine, terpene resin, acrylic acid ethyl acetate The combination of ester and silicone resin, the weight ratio is 1:1:1:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com