Gradient condensation type gas heat supply unit

A gradient condensing and heating unit technology, applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of complex equipment structure, high engineering cost, and huge system, so as to improve thermal efficiency, safe operation, The effect of increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

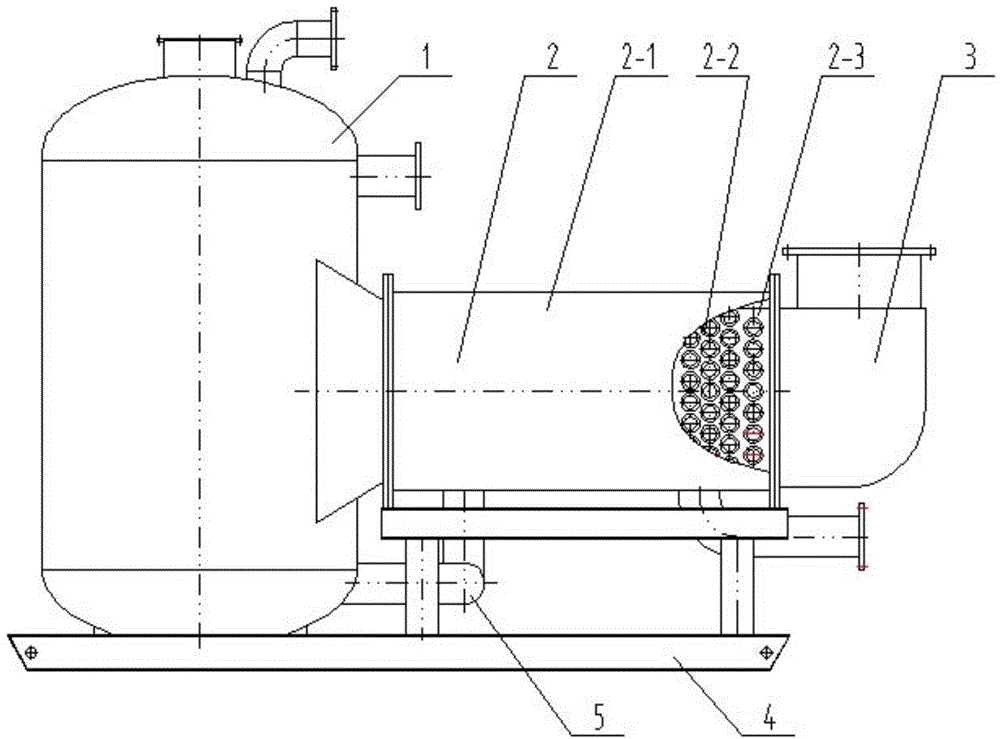

[0014] Attached below figure 1 The present invention is further described, and the specific implementation method is described in detail.

[0015] A gradient condensing gas heating unit, comprising a body (1), a high-efficiency heat exchange device (2), a tail smoke box (3), a base (4), and a connecting pipeline (5).

[0016] The high-efficiency heat exchange device (2) is composed of an outer shell (2-1), a tube bundle (2-2), and a square inner cylinder (2-3). A trapezoidal array of hole bundles in rows, square flanges for connecting the body (1) and the rear smoke box (4) are welded at both ends, and the trapezoidal arrays on both sides of the tube bundle (2-2) and the square inner cylinder (2-3) are arranged The hole bundle of the plate is formed by welding, so that the tube bundle (2-2) and the smoke outlet of the body (1) are horizontally and vertically arranged to form a cross-flow form of the smoke discharged in the horizontal direction from the body (1). The outer ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com