Vertical efficient water-cooling condenser

A water-cooled, condenser technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problem that the heat exchange efficiency of the condenser is not very high, so as to improve the heat exchange efficiency, increase the contact area, improve the The effect of outflow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

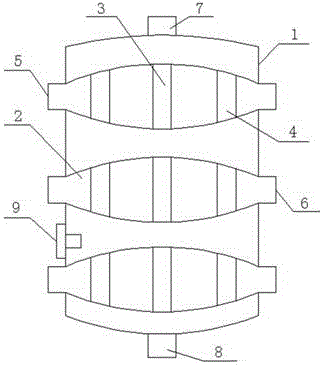

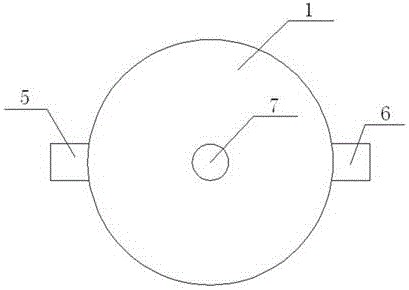

[0017] A vertical high-efficiency water-cooled condenser with the advantages of high heat exchange efficiency, such as figure 1 , figure 2 As shown, it is specially arranged as the following structure: including a barrel body 1, a plurality of cooling water tanks 2 arranged in the barrel body 1 sequentially from top to bottom; The water tank 2 is provided with a through hole, and the two ends of the cooling water tank 2 are respectively connected with a cooling water inlet pipe 5 and a cooling water outlet pipe 6; Condensed water outlet pipe 8; the side wall of the barrel body 1 is provided with a temperature monitor 9, and the temperature monitor 9 includes a temperature display arranged on the outer wall of the barrel body 1 and a temperature sensor arranged on the inner wall of the barrel body 1. The cooling water tank 2 is a box whose middle height is higher than that of the surroundings, so that the hot air can be guided to flow around the cooling water tank, the contac...

Embodiment 2

[0019] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 1 As shown, the following arrangement structure is adopted in particular: a plurality of uniformly distributed first through-holes 3 and second through-holes 4 are respectively opened in the middle and around the box body 1, and the diameter of the first through-hole 3 is smaller than that of the second through-hole. The pipe diameter of the through hole 4. Furthermore, the volumes of the first through hole 3 and the second through hole 4 are equal to the volume of the hot gas intake pipe 7 .

Embodiment 3

[0021] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 As shown, the following arrangement structure is adopted in particular: the bottom of the barrel body 1 is a curved thin plate whose middle part is lower than the surrounding; the design of the curved surface can facilitate the accumulation of condensed water, and facilitate the flow of condensed water out of the box body 1 through the condensed water outlet pipe 8 outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com