Multi-pass regenerators for regenerative cryogenic refrigerators

A low-temperature refrigerator and regenerator technology, which is applied in the direction of refrigerators, superheaters, refrigeration components, etc., can solve the problems of increasing flow resistance loss, increasing the volume of regenerators, and reducing the filling space of cold storage materials, so as to reduce heat transfer Loss, porosity reduction, and effect of improving refrigeration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

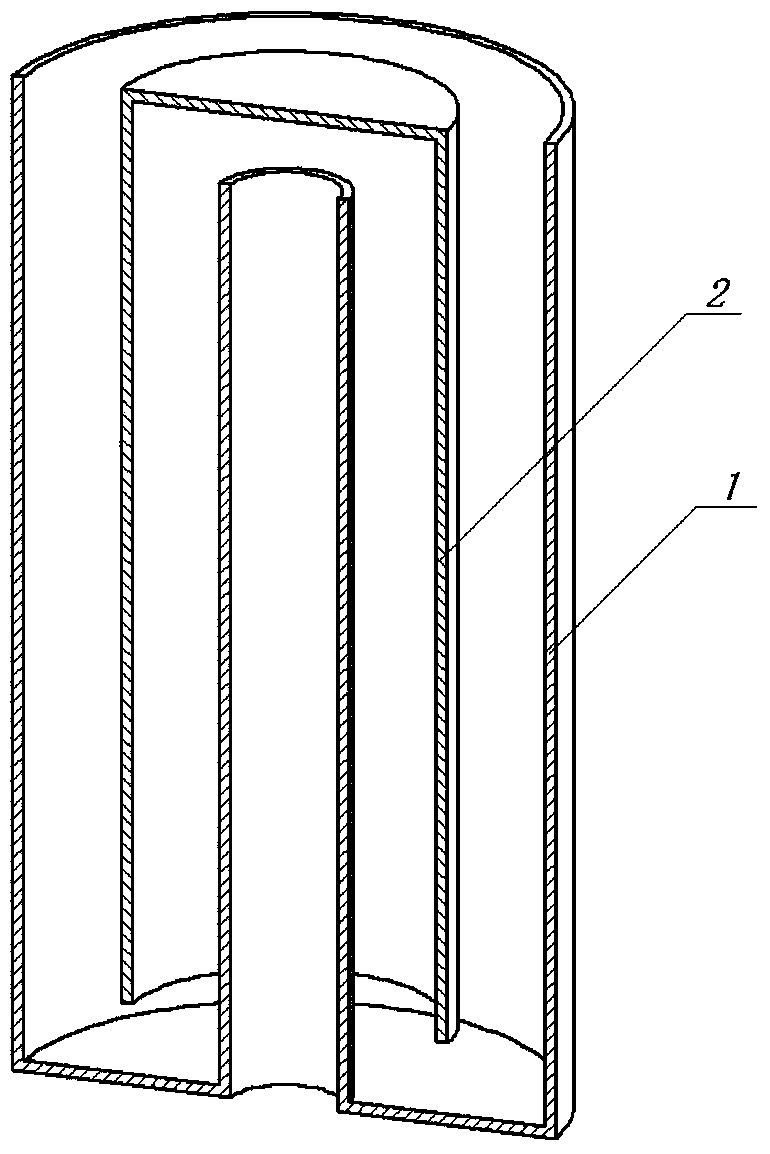

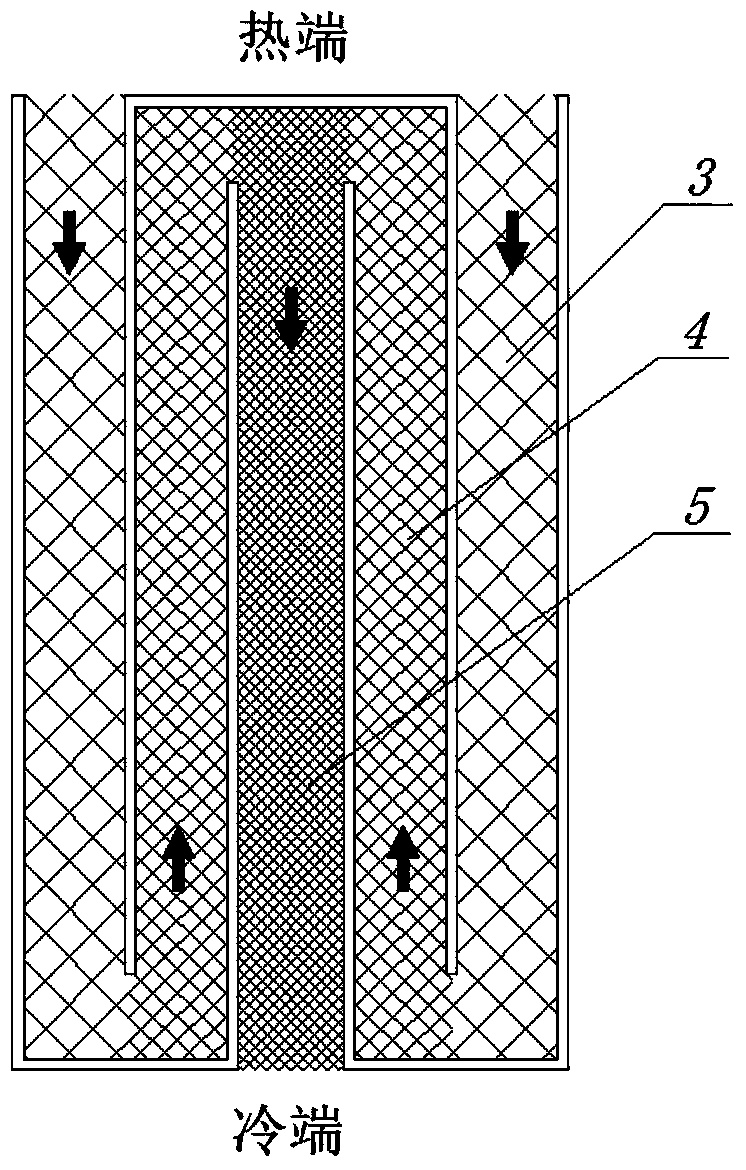

[0028] Such as figure 1 and figure 2 As shown, this embodiment includes: a cylindrical inner thermal barrier layer 2 and an outer thermal barrier layer 1 coaxially arranged from the inside to the outside, and divides the interior of the regenerator into three ring-shaped areas, which are respectively filled from the inside to the outside Low temperature section filler 5, medium temperature section filler 4 and high temperature section filler 3.

[0029] The thermal barrier layers 1 and 2 both have a thickness of 0.5 mm and are made of polytetrafluoroethylene, which ensures a good thermal barrier effect while minimizing the space filled with the cold storage material of the regenerator.

[0030] The low-temperature section packing 5, the medium-temperature section packing 4 and the high-temperature section packing 3 are all made of phosphor bronze wire mesh, and the porosity is 63%, 75% and 90% respectively, and the flow resistance is effectively reduced by increasing the por...

Embodiment 2

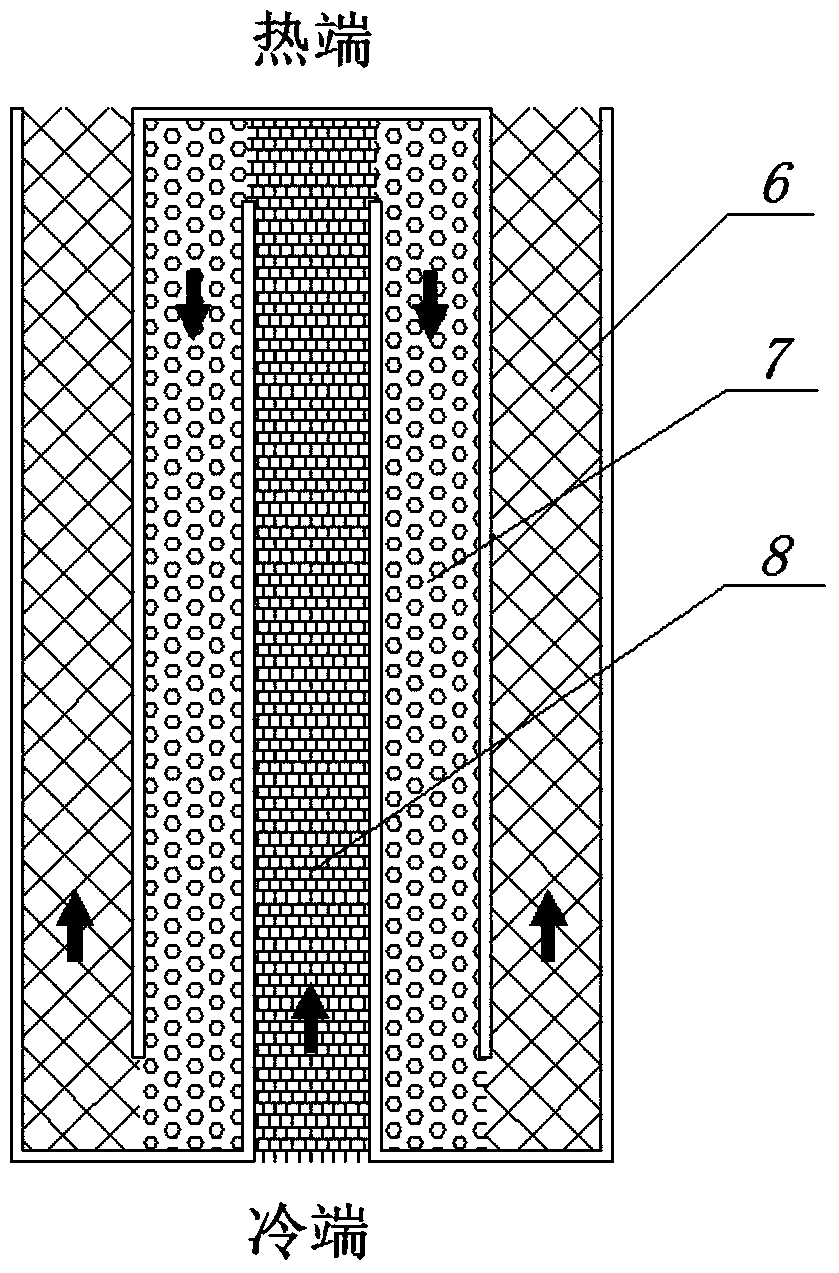

[0034] Such as figure 1 and image 3 As shown, this embodiment includes: a cylindrical inner thermal barrier layer 2 and an outer thermal barrier layer 1 coaxially arranged from the inside to the outside, and divides the interior of the regenerator into three ring-shaped areas, which are respectively filled from the inside to the outside Low temperature section packing 8, medium temperature section packing 7 and high temperature section packing 6.

[0035] The thicknesses of the thermal barrier layers 1 and 2 are both 0.7mm, and the material is polyimide.

[0036] The low-temperature section filler 8, the medium-temperature section filler 7 and the high-temperature section filler 6 are respectively made of magnetic cold storage material, lead shot and phosphor bronze wire mesh, and the porosity is 59%, 74% and 88% respectively.

[0037] In this embodiment, the air inlet at the cold end and the air outlet at the hot end are taken as an example: the cold air flow entering from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com