A simple and convenient detection apparatus for collecting lens surface types and a detection method based on the apparatus

A detection device and lens technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the inner surface shape of large-diameter collection lenses cannot be detected, etc., and achieve the effect of easy detection method, simple device, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

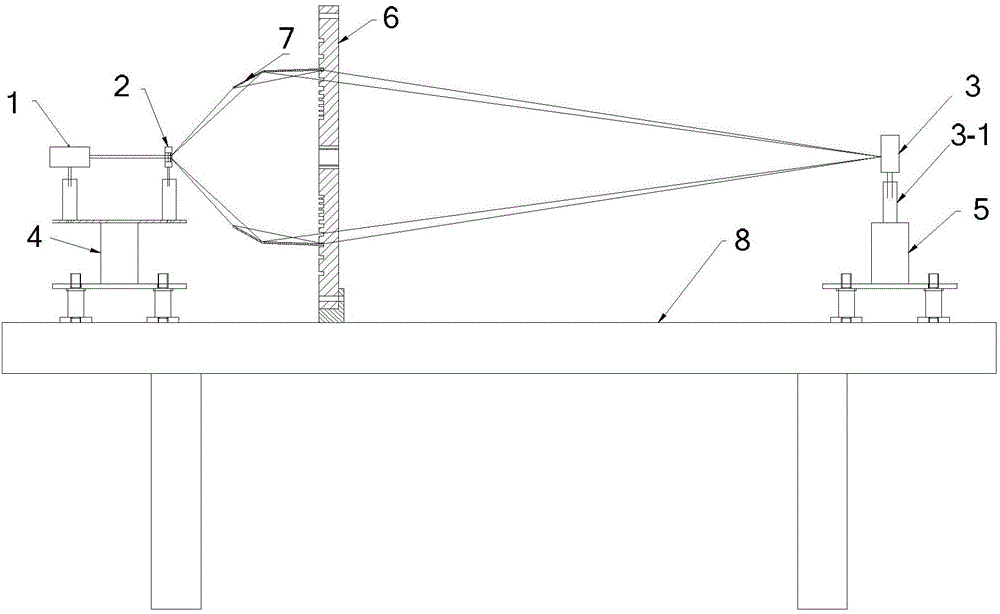

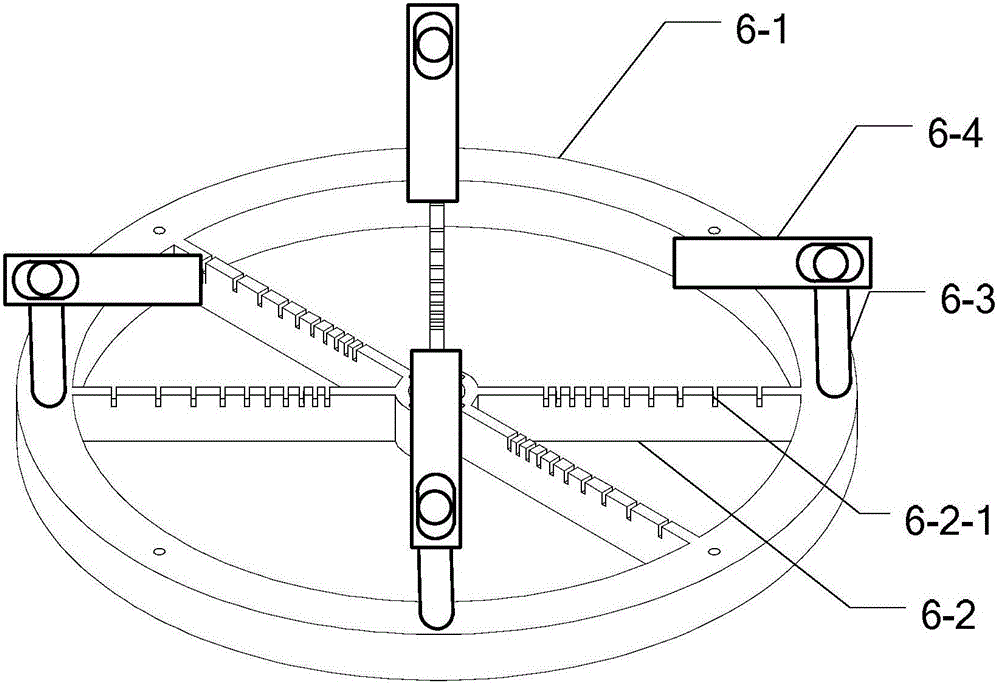

[0024] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment in detail, the simple and convenient detection device of collecting lens surface described in this embodiment, comprises semiconductor laser 1, frosted glass 2, CCD sensor 3, the first five-dimensional adjustment table 4, the second five-dimensional adjustment table 5, collecting Lens support 6 and computer;

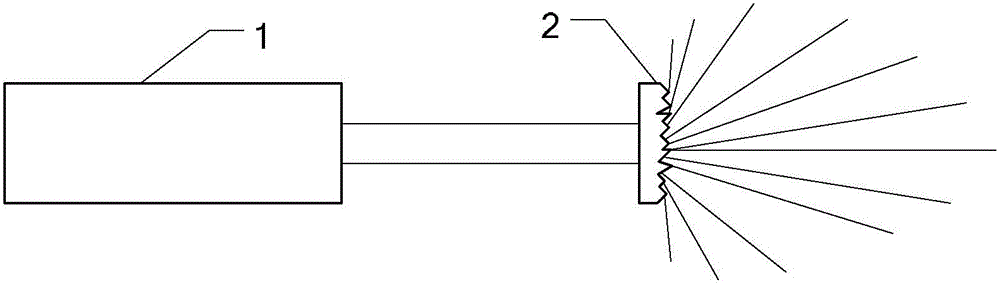

[0025] A black paper is pasted on the frosted glass 2, and a small round hole is opened on the black paper;

[0026] The laser light emitted by the semiconductor laser 1 is incident on the ground glass 2, and the light transmitted through the small round hole of the ground glass 2 is converged to the CCD sensor 3 through the collecting lens 7;

[0027] The collection lens support 6 fixes the collection lens 7 in the optical path, the semiconductor laser 1 and the frosted glass 2 are fixed on the first five-dimensional adjustment table 4, the CCD sensor 3 is fixed on the se...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment is a further description of the simple detection device for collecting lens surface shape described in Embodiment 1. In this embodiment, the small round hole is a round hole of Φ3mm.

[0035] The diameter of the capillary is usually Φ3mm, so the small hole is also a round hole of Φ3mm.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment further describes the simple detection device for collecting lens surface shape described in Embodiment 1 or 2. In this embodiment, the semiconductor laser 1 outputs visible light.

[0037] The semiconductor laser 1 outputs visible light, which facilitates the debugging of the optical path, and red light is suitable for visible light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com