Making system for underwater 3D terrain of construction position of trailing suction hopper dredger

A trailing suction dredger, 3D technology is applied in the field of systems where trailing suction dredger construction provides underwater 3D terrain, and can solve problems affecting seabed sounding accuracy, seabed shape distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

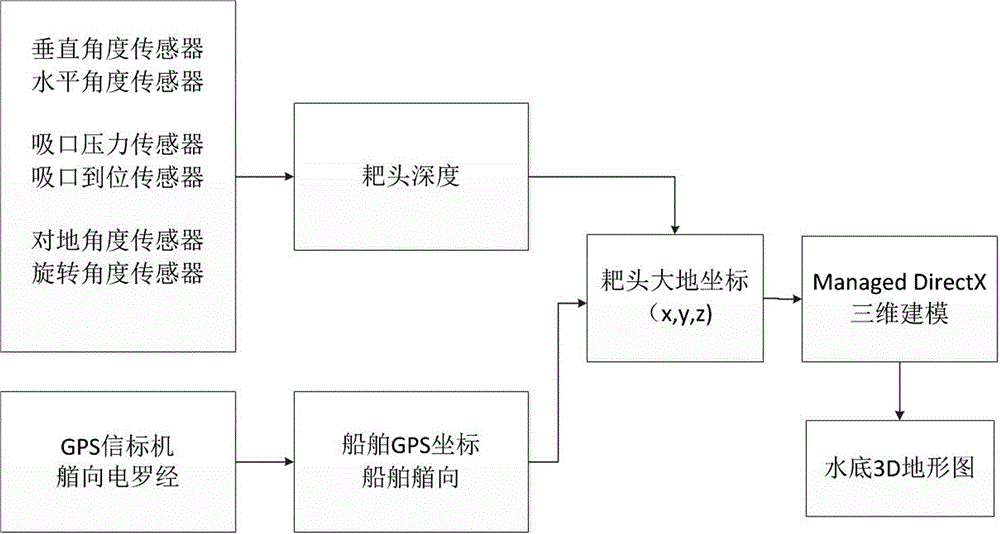

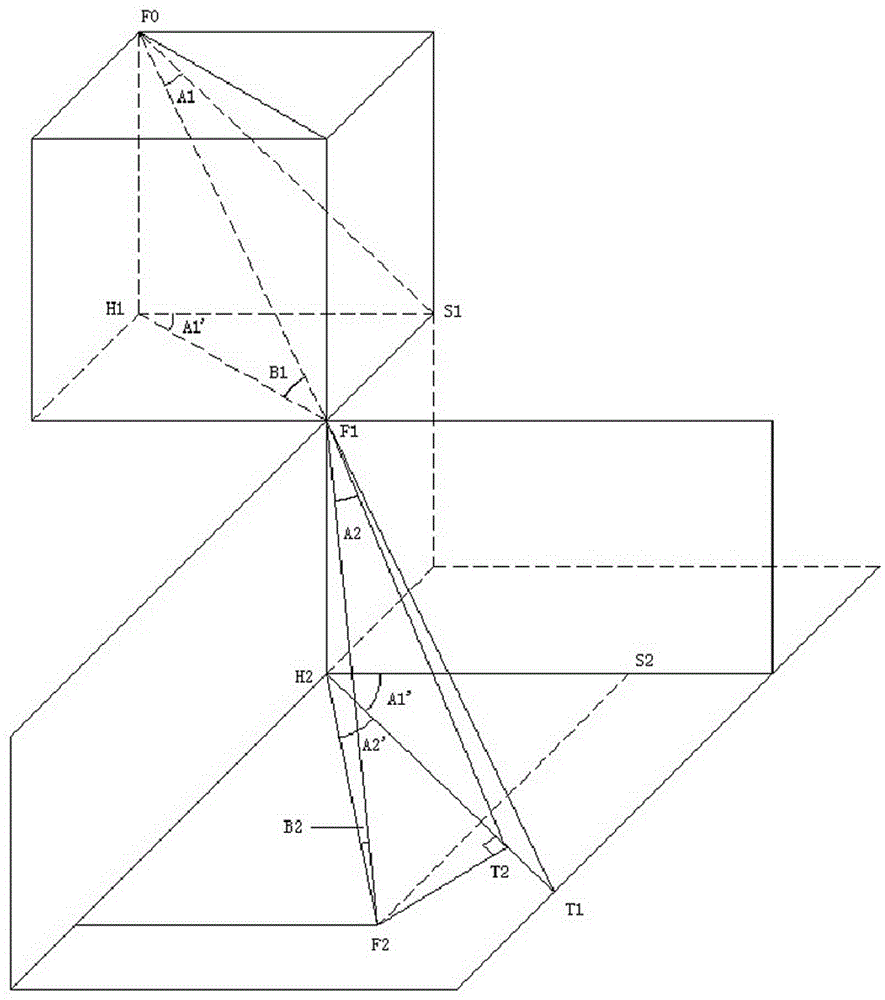

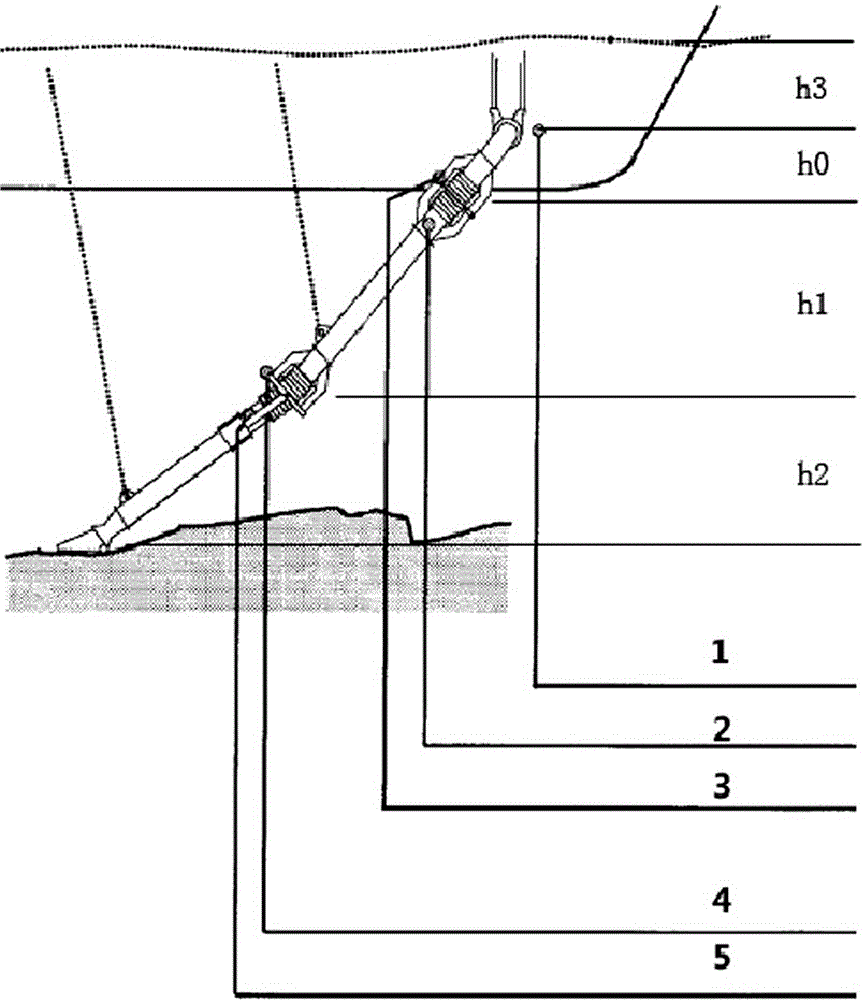

[0012] This embodiment includes a rake arm position system consisting of a set of rake arm equipment and a programmable controller located at the dredging console, a set of GPS beacons for obtaining the GPS position of the ship, a gyro compass for the ship's heading, and a ship control computer. The location system consists of a data processing system for calculating the geodetic coordinates of the rake head and establishing a data model, and a graphics generation and display system located in the dredging console. The horizontal angle sensor of the upper rake pipe, the vertical angle sensor of the upper rake pipe, the horizontal angle sensor of the lower rake pipe, the vertical angle sensor of the lower rake pipe are installed on the rake arm, and the suction port pressure sensor is installed to detect the state of the suction port of the rake arm. The installation position of the sensor is: the vertical angle sensor of the upper rake pipe (2) is installed at the vertical side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com