Method for detecting chemical components of quenched plate

A detection method and technology of chemical composition, applied in the fields of electrical excitation analysis, material excitation analysis, preparation of test samples, etc., can solve problems such as troublesome analysis and research work, inaccuracy, avoid adverse effects, reduce data distortion, The effect of analyzing the results accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

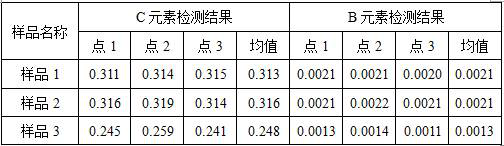

[0028] The present embodiment selects 3 sample pieces that the trade mark is 34MnB5, and the numbering of 3 sample pieces is sample 1, sample 2, sample 3 successively, then carry out following operations:

[0029] (1) Sample 2 and sample 3 were quenched under the same conditions, the heating temperature was 900°C, the holding time was 5 minutes, and water was used as the quenching medium; sample 1 was not treated.

[0030] (2) Preparation of erosion solution: first add 150ml of deionized water to a 300ml beaker, then slowly add 40ml of concentrated hydrochloric acid, 3ml of concentrated sulfuric acid, 1g of sodium lauryl sulfate, and finally add 1ml of hydrogen peroxide, mix well, and set aside .

[0031] (3) Erosion of the oxide layer on the surface of the quenching plate: immerse sample 2 in the etching solution, heat it at a low temperature on an electric heating plate until the temperature of the etching solution is 40°C, and then erode for 300 seconds. After taking it out...

Embodiment 2

[0039] The present embodiment selects 3 sample pieces that the trade mark is 34MnB5, and the numbering of 3 sample pieces is sample 1, sample 2, sample 3 successively, then carry out following operations:

[0040] (1) Perform quenching treatment on samples 2 and 3 under the same conditions, the heating temperature is 900°C, the holding time is 5 minutes, and water is used as the quenching medium; sample 1 is not treated.

[0041] (2) Preparation of erosion solution: first add 150ml of deionized water to a 300ml beaker, then slowly add 50ml of concentrated hydrochloric acid, 5ml of concentrated sulfuric acid, 1.5g of sodium lauryl sulfate, and finally add 2ml of hydrogen peroxide, mix well, wait use.

[0042] (3) Erosion of the oxide layer on the surface of the quenching plate: immerse sample 2 in the etching solution, heat it at a low temperature on an electric heating plate until the temperature of the etching solution is 50°C, and then erode for 240 seconds. After taking it ...

Embodiment 3

[0050] The present embodiment selects 3 sample pieces that the trade mark is 22MnB5, and the numbering of 3 sample pieces is sample 1, sample 2, sample 3 successively, then carry out following operations:

[0051] (1) Perform quenching treatment on samples 2 and 3 under the same conditions, the heating temperature is 900°C, the holding time is 5 minutes, and water is used as the quenching medium; sample 1 is not treated.

[0052] (2) Preparation of erosion solution: first add 150ml of deionized water to a 300ml beaker, then slowly add 60ml of concentrated hydrochloric acid, 6ml of concentrated sulfuric acid, 2g of sodium lauryl sulfate, and finally add 1ml of hydrogen peroxide, mix well, and set aside .

[0053](3) Erosion of the oxide layer on the surface of the quenching plate: immerse sample 2 in the etching solution, heat it at a low temperature on an electric heating plate until the temperature of the etching solution is 55°C, and then erode for 180 seconds. After taking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com