A fiber bragg grating transverse pressure transducer system based on a microwave photonic filter and a measuring method thereof

A technology of fiber optic Bragg and microwave photons, which is applied to fluid pressure measurement, force measurement, and measurement devices using optical methods, and can solve problems such as low lateral pressure sensitivity, difficult implementation and practicality, and inability to accurately measure lateral pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

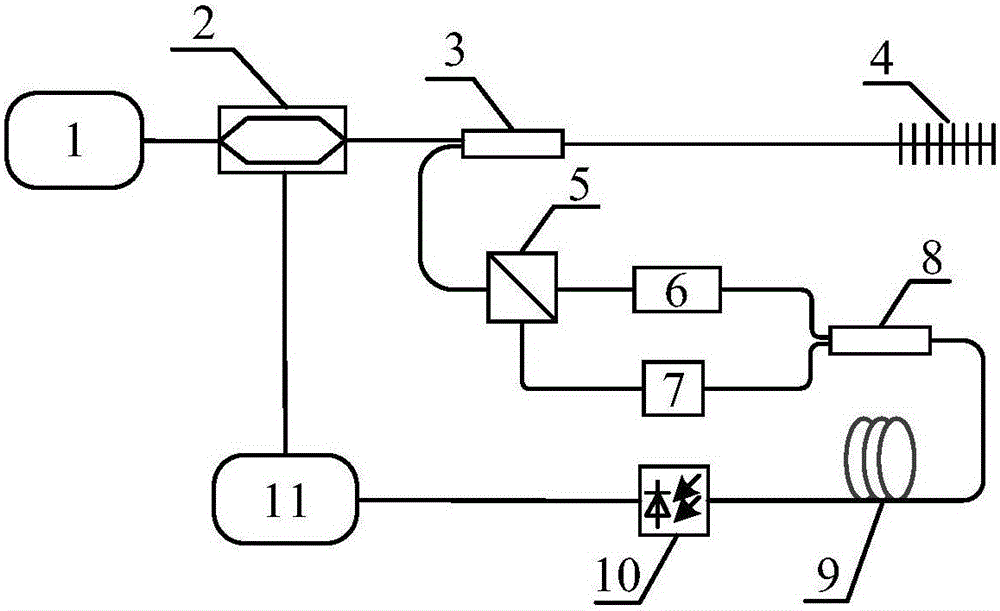

[0015] see figure 1 As shown, the present invention provides a fiber Bragg grating lateral pressure sensing system based on a microwave photon filter, adopting a fiber Bragg grating made of a common single-mode fiber as a sensing unit, which includes a broadband light source 1, an electro-optical intensity modulator 2, First fiber coupler 3, fiber Bragg grating 4, fiber polarization beam splitter 5, adjustable fiber delay line 6, adjustable fiber attenuator 7, second fiber coupler 8, dispersion compensation fiber 9, photodetector 10 and vector network analyzer11.

[0016] refer to figure 1 As shown, the optical input end of the electro-optic intensity modulator 2 is connected to the output end of the broadband light source 1, its output port is connected to an input port of the first fiber coupler 3, and its radio frequency input end is connected to the radio frequency output of the vector network analyzer 11 The ports are connected; the fiber Bragg grating 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com