A power diode forward dynamic resistance test device

A power diode and dynamic resistance technology, applied in the field of power diode forward dynamic resistance testing devices, can solve the problems of testing without considering the forward dynamic resistance of power diodes, and achieve automatic detection and display, low mutual interference, and high performance. Effects of Accuracy and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

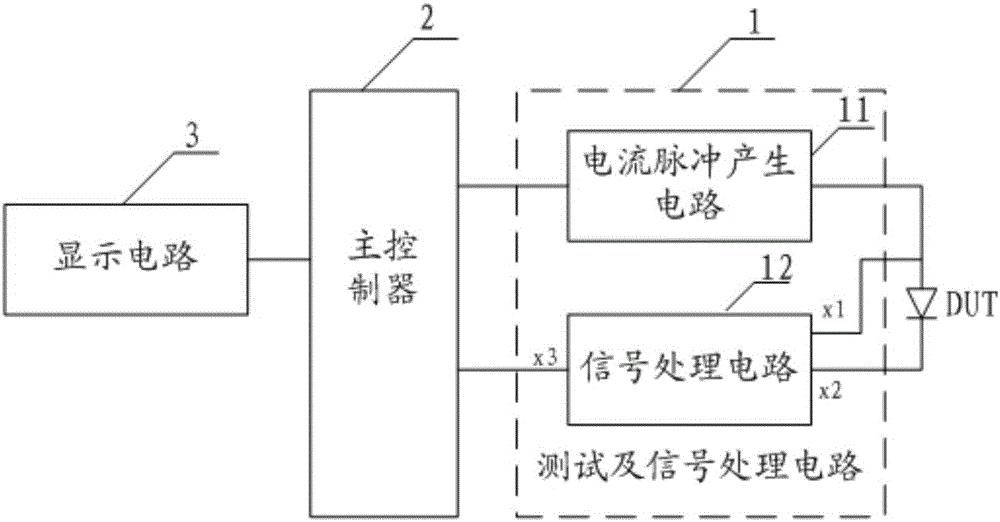

[0033] like Figure 1 to Figure 3 As shown, in the embodiment of the present invention, a power diode forward dynamic resistance test device is provided, including a test and signal processing circuit 1, a display circuit 3, and a main control connected to the test and signal processing circuit and the display circuit 3. device 2; where,

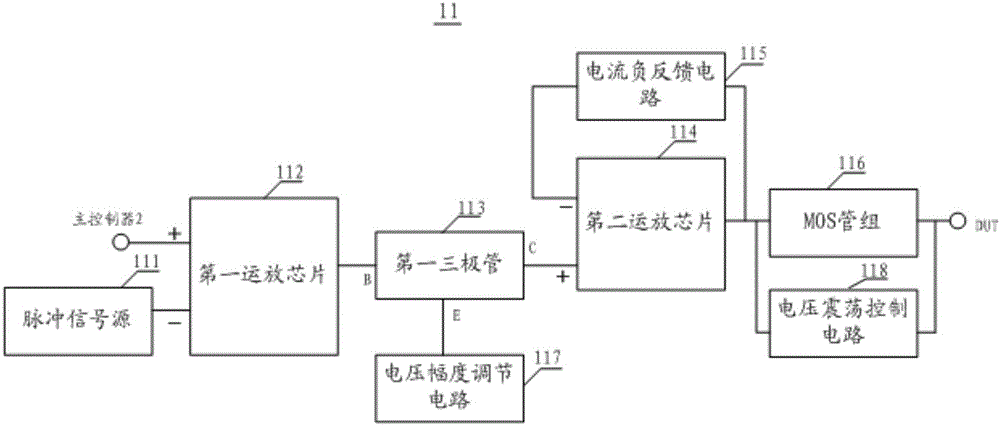

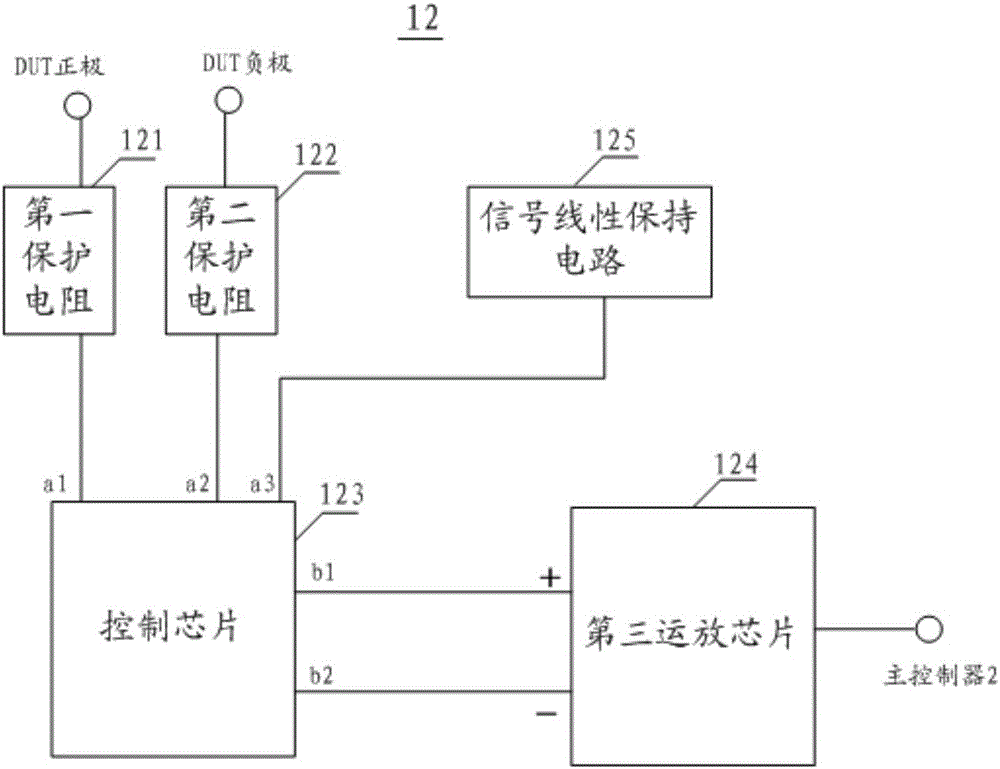

[0034] The test and signal processing circuit 1 includes a current pulse generation circuit 11 for loading a large current pulse signal on the power diode DUT under test and turning it on, and a current pulse generating circuit 11 for acquiring the voltage signal generated after the power diode DUT under test is turned on and connecting it with the power diode DUT. The signal processing circuit 12 for processing the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com