Silicon chip fast handing over device

A handover device and silicon wafer technology, which is applied in photolithographic process exposure equipment, transportation and packaging, instruments, etc., can solve the problems of not performing silicon wafer pre-alignment functions, reduce handover time, increase production capacity, and ensure high The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

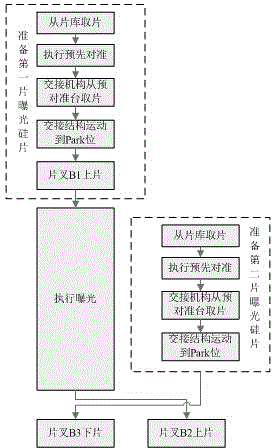

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

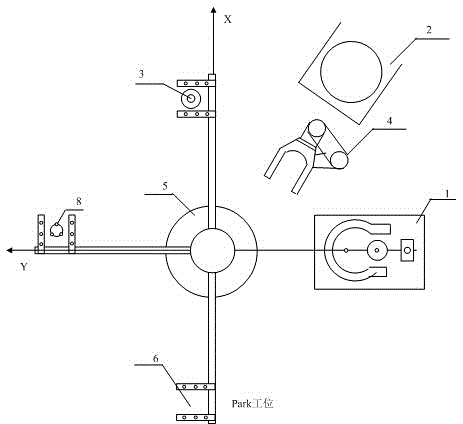

[0019] figure 1 It is a transmission layout diagram of the silicon wafer rapid transfer device of the present invention. Such as figure 1 As shown, the silicon wafer transfer system is composed of a pre-alignment unit 1 , a wafer storage unit 2 , an unloading buffer table 3 , a silicon wafer transfer manipulator 4 , and a silicon wafer transfer mechanism 5 . The pre-alignment unit 1 mainly realizes the centering and orientation of silicon wafers; the wafer storage unit 2 is mainly responsible for the storage of silicon wafers; the unloading cache table 3 realizes the caching of silicon wafers after exposure; the silicon wafer transfer robot 4 realizes the silicon wafer from the wafer storage The movement of silicon wafers between unit 2 to pre-alignment unit 1, and from the next buffer table 3 to the library unit 2.

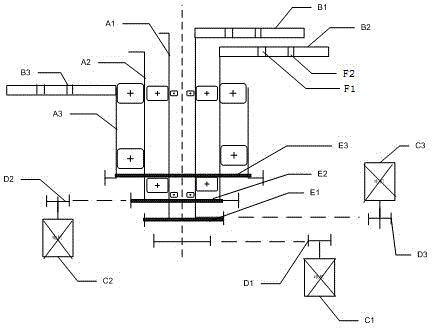

[0020] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com