Preparation method of perfluorosulfonic acid proton exchange membrane

A technology of proton exchange membrane and perfluorosulfonic acid, applied in the field of proton exchange membrane, can solve the problems of long process cycle, complex process and high cost of film formation, and achieve the effects of simple preparation process, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

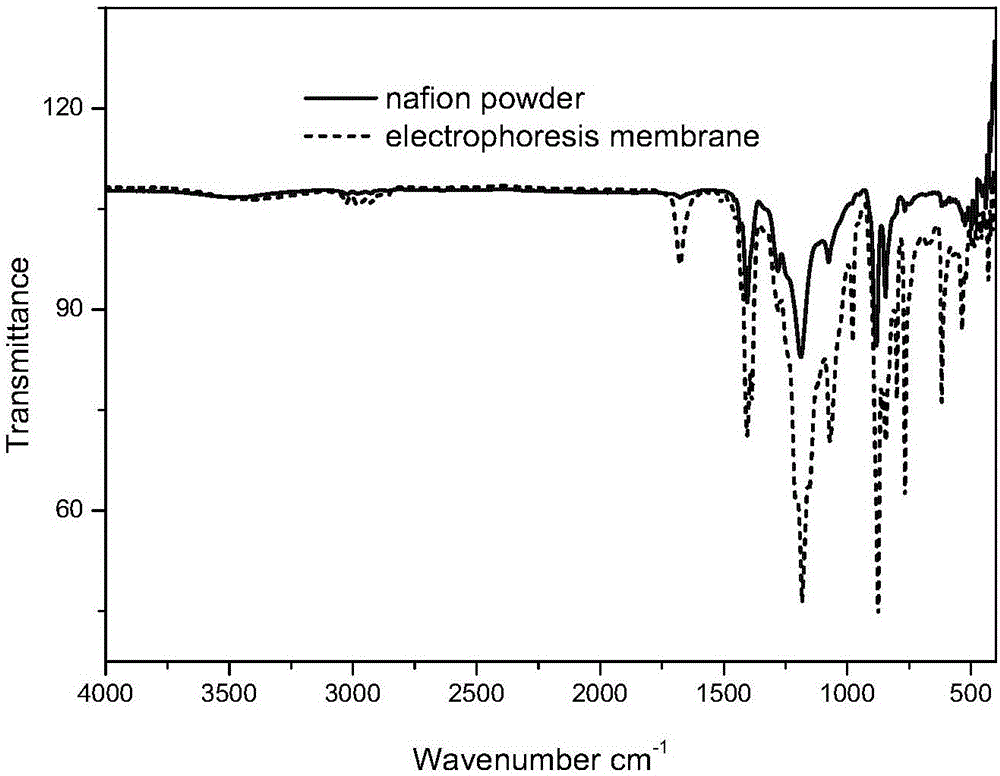

Image

Examples

Embodiment 1

[0025] S1: Weigh 0.15g of perfluorosulfonic acid resin, 14ml of ethanol, and 7ml of N-methylpyrrolidinone;

[0026] S2: Add N-methylpyrrolidinone into ethanol, stir for 0.1h until uniform to prepare a mixed solvent;

[0027] S3: Add weighed perfluorosulfonic acid resin to the mixed solvent prepared in step S2, and stir for 3 hours until the particles are uniformly dispersed to obtain a stable suspension;

[0028] S4: With the graphite sheet as the negative pole piece and the conductive glass as the positive pole piece, insert the two electrode pole pieces into the suspension prepared in step S3, apply a 50V DC voltage, the electrode distance is 5mm, electrophoresis for 300s, and obtain perfluorinated Sulfonic acid proton exchange membrane.

[0029] Further, in step S4 described in this embodiment, under the same process conditions and parameters, the positive pole piece is also electrophoresed using copper, aluminum and platinum pieces respectively.

Embodiment 2

[0031] S1: Weigh 0.05g of perfluorosulfonic acid resin, 20ml of ethanol, and 5ml of N-methylpyrrolidone;

[0032] S2: Add N-methylpyrrolidinone into ethanol, stir for 0.1h until uniform to prepare a mixed solvent;

[0033] S3: Add weighed perfluorosulfonic acid resin to the mixed solvent prepared in step S2, and stir for 2.5 hours until the particles are uniformly dispersed to obtain a stable suspension;

[0034] S4: With the graphite sheet as the negative pole piece and the conductive glass as the positive pole piece, insert the two electrode pole pieces into the suspension prepared in step S3, apply a 50V DC voltage, the electrode distance is 5mm, electrophoresis for 300s, and obtain perfluorinated Sulfonic acid proton exchange membrane.

Embodiment 3

[0036] S1: Weigh 0.05g of perfluorosulfonic acid resin, 10ml of ethanol, and 5ml of N-methylpyrrolidinone;

[0037] S2: Add N-methylpyrrolidinone into ethanol, stir for 0.1h until uniform to prepare a mixed solvent;

[0038] S3: Add weighed perfluorosulfonic acid resin to the mixed solvent prepared in step S2, and stir for 2 hours until the particles are uniformly dispersed to obtain a stable suspension;

[0039] S4: With the graphite sheet as the negative pole piece and the conductive glass as the positive pole piece, insert the two electrode pole pieces into the suspension prepared in step S3, apply a 50V DC voltage, the electrode distance is 5mm, electrophoresis for 300s, and obtain perfluorinated Sulfonic acid proton exchange membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com