Deicing tackle for power transmitting line

A transmission line and pulley technology, applied in the field of transmission line maintenance devices, can solve problems such as poor, aging sealing effect of components, etc., and achieve the effects of improving clearance rate, improving efficiency, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

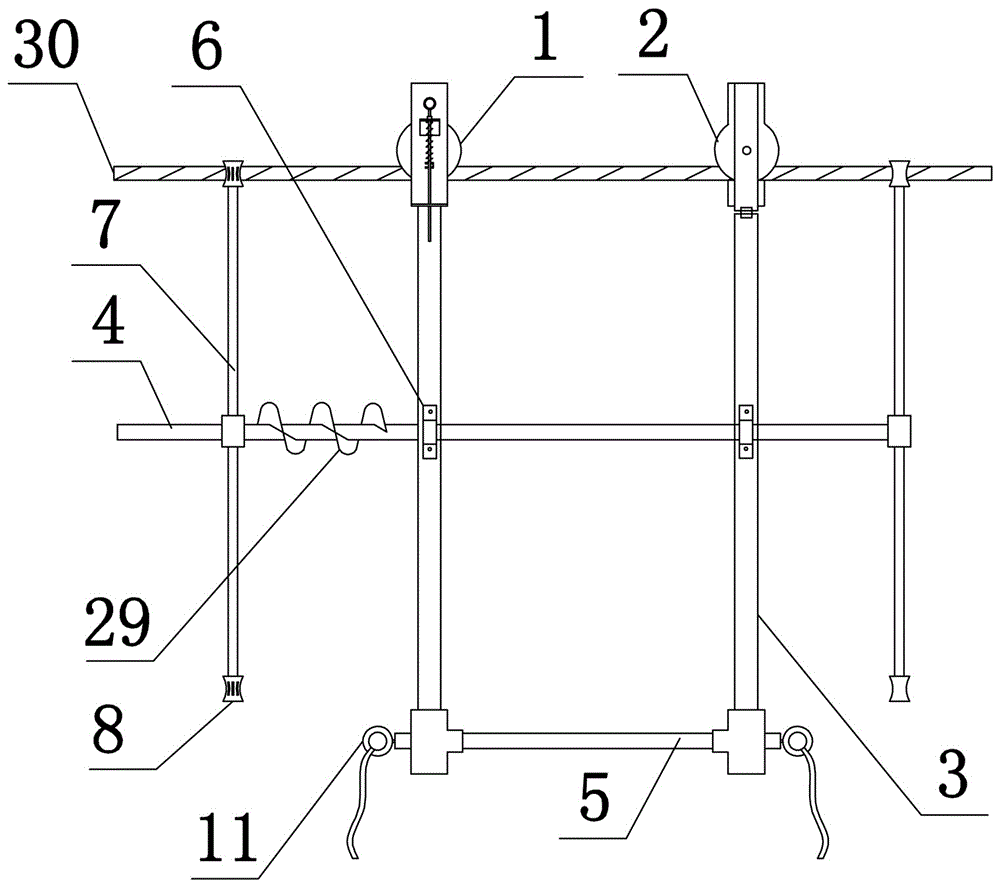

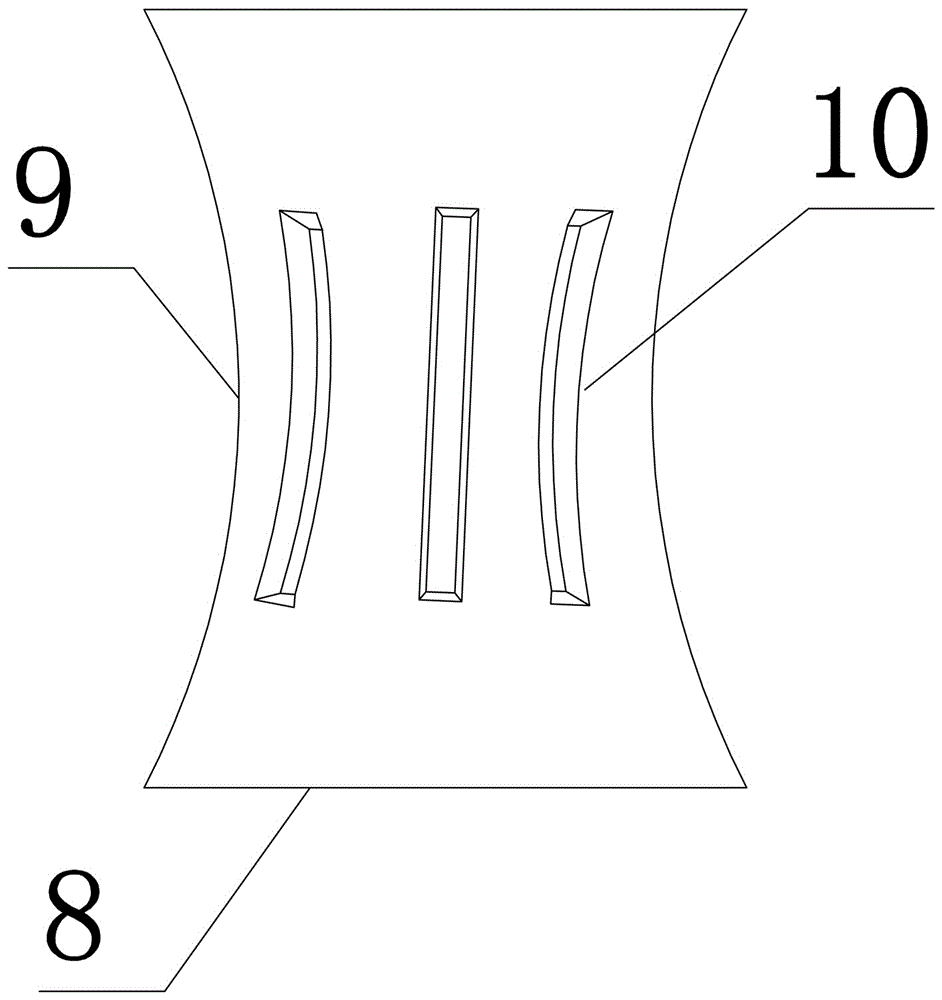

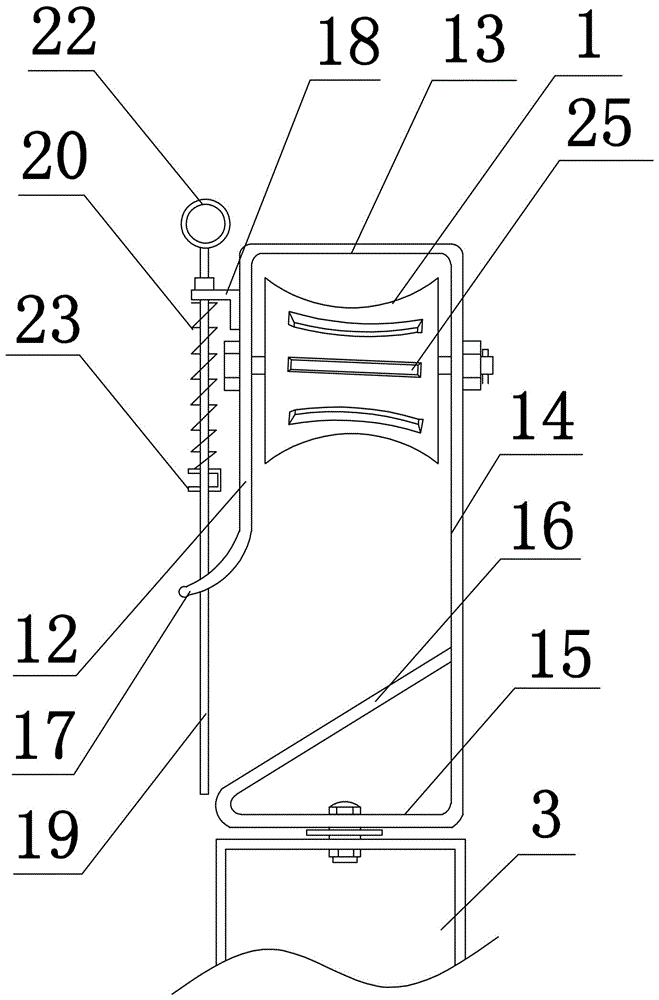

[0032] like figure 1 and figure 2 As shown, the present invention includes a support frame, a pulley one 1 and a pulley two 2, the support frame includes two vertical bars 3, an upper cross bar 4 and a lower cross bar 5, two hoops 6 are arranged on the upper cross bar 4, Two hoops 6 and the lower cross bar 5 are all fixedly connected with the two vertical bars 3, and the upper cross bar 4 is provided with a driving mechanism and a knocking mechanism. The driving mechanism is a screw rod 29, and the screw rod 29 is fixed on the surface of the upper cross bar 4 and With the coaxial rotation of the upper cross bar 4, the screw rod 29 is wound with a stay wire (not shown in the figure). The knocking mechanism includes a connecting rod 7 and an ice hammer 8 arranged at the end of the connecting rod 7. The ice hammer 8 is a columnar body, and the ice hammer 8 A groove 9 is provided on the surface, and the groove 9 is matched with the outer surface of the power transmission wire. The...

Embodiment 2

[0036] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 5 As shown, a magnet one 27 is set between the inclined plate 16 and the horizontal plate two 15, and the lower end of the pull rod 19 is fixedly connected to the magnet two 28 which is attracted to each other by the magnet one 27. For the arc groove structure that cooperates with magnet one 27, the suction force F1 when magnet one 27 contacts with magnet two 28 is greater than the maximum elastic force F2 of spring 20, and the suction force F1 when magnet one 27 contacts with magnet two 28 is smaller than this Invent the self-weight G of the whole.

[0037] In this embodiment, the mutual attraction between the magnet one 27 set between the inclined plate 16 and the horizontal plate two 15 and the magnet two 28 set at the lower end of the pull rod 19 can effectively ensure the effect of automatic sealing, especially when the spring 20 is irreversibly shortened. ...

Embodiment 3

[0039] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 6 to Figure 8 As shown, blunt protrusion one 25, blunt protrusion two 26 and blunt protrusion three 10 are all cross-shaped. Image 6 Only show the structure of the blunt protrusion three 10, the drive mechanism is a grooved roller 31, the groove bottom of the grooved roller 31 is provided with a tooth one 32, and a transmission belt 33 is arranged in the grooved roller 31, and the transmission belt 33 is arranged to match with the tooth one 32 Tooth 2:34. In this embodiment, the grooved roller 31 replaces the screw rod 29 in Embodiment 1, and the transmission belt 33 replaces the pull wire of Embodiment 1. The gear cooperation between the grooved roller 31 and the conveyor belt 33 effectively prevents the gap between the transmission belt 33 and the knocking mechanism. Slippage occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com