Electrochromism solution for gridiron and electrochromism method thereof

A technology for electroplating chromium and solution, applied in the field of metal surface treatment, can solve the problems of unsuitable chromium electroplating and simple composition, and achieve the effects of strong corrosion resistance, enhanced coating thickness and enhanced coating activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the manufacturer's conditions, and the unspecified implementation conditions are usually conventional experimental conditions.

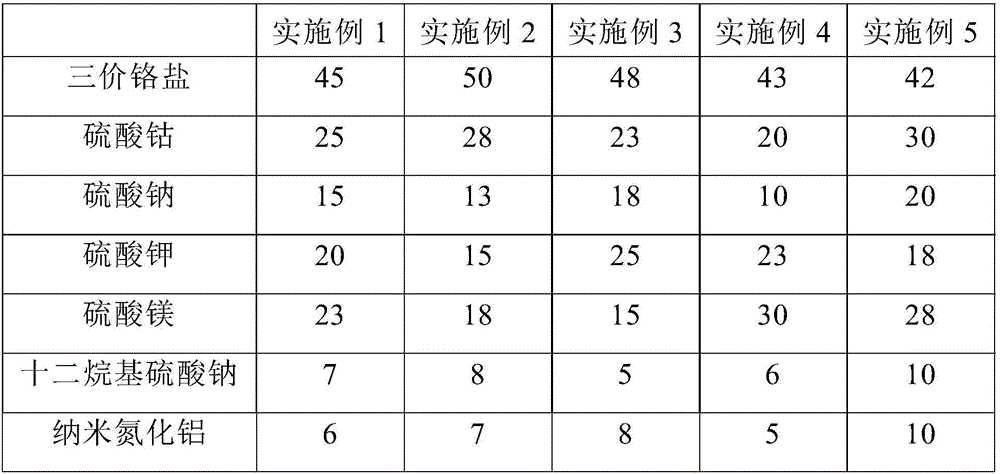

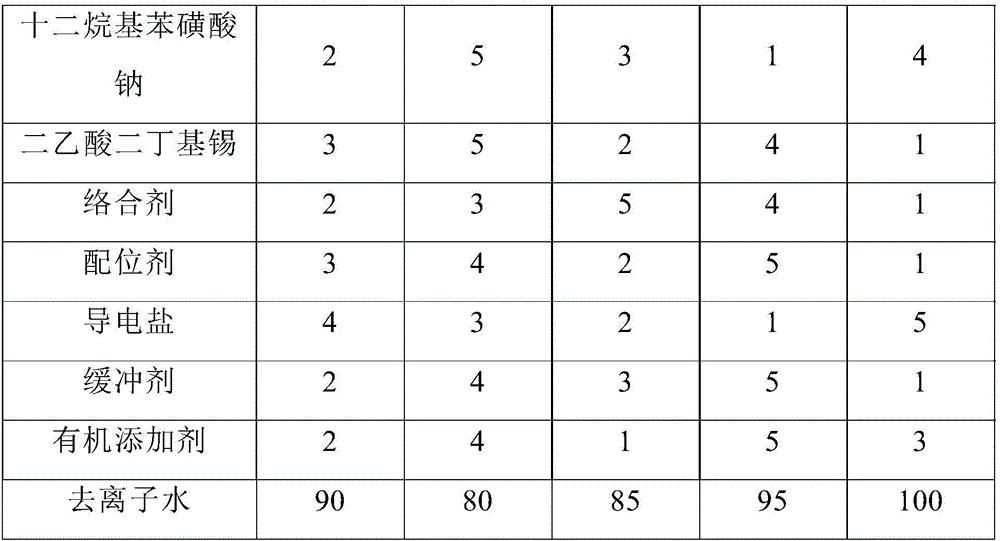

[0030] An electroplating solution for grills provided by the present invention, the solution includes the following components by weight: trivalent chromium salt: 40-50 parts, cobalt sulfate: 20-30 parts, sodium sulfate: 10-20 parts, Potassium sulfate: 15-25 parts, magnesium sulfate: 15-30 parts, sodium dodecyl sulfate: 5-10 parts, nano-aluminum nitride: 5-10 parts, sodium dodecylbenzenesulfonate: 1-5 parts Parts, dibutyltin diacetate: 1-5 parts, complexing agent: 1-5 parts, complexing agent: 1-5 parts, conductive salt: 1-5 parts, buffer agent: 1-5 parts, organic additives: 1 ~5 parts, deionized water: 80~100 parts.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com