Lubricating oil secondary cooling system for wind power gear box

A wind power gearbox and secondary cooling technology, applied in gear lubrication/cooling, wind power generation, belt/chain/gear, etc., can solve the problem of decreased cooling power of the wind cooler, weakened cooling effect of the gearbox, and difficulty in cleaning solid sludge, etc. problems, to achieve the effect of improving cooling capacity, good cooling effect, and reducing high temperature faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

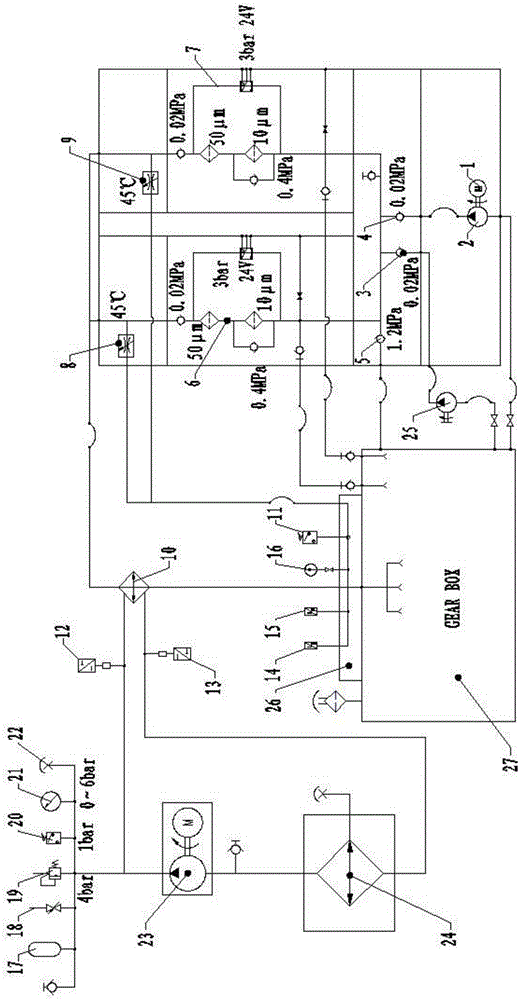

[0020] The specific embodiment of the present invention is shown in the accompanying drawings. The secondary cooling system for the lubricating oil of the wind power gearbox includes a primary cooling system. The primary cooling system includes: a motor 1, an oil pump 2, a single shut-off valve I3, a single shut-off valve II4, a safety valve 5, Double-precision filter I6, double-precision filter II7, temperature control valve I8, temperature control valve II9, plate cooler 10 and mechanical pump 25; the oil suction ports of oil pump 2 and mechanical pump 25 are connected to gear box 27, mechanical pump 25 and The oil outlet of oil pump 2 is connected to the inlets of double-precision filter I6 and double-precision filter II7 through one-way stop valve I3 and one-way stop valve II4 respectively; the outlets of double-precision filter I6 and double-precision filter II7 are respectively connected to the temperature control The valve I8 is connected to the inlet of the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com