Flip light emitting diode (LED) with ODR structure and preparation method, and flip high-voltage LED

A light-emitting diode, flip-chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of improving reflectivity, improving chip brightness, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

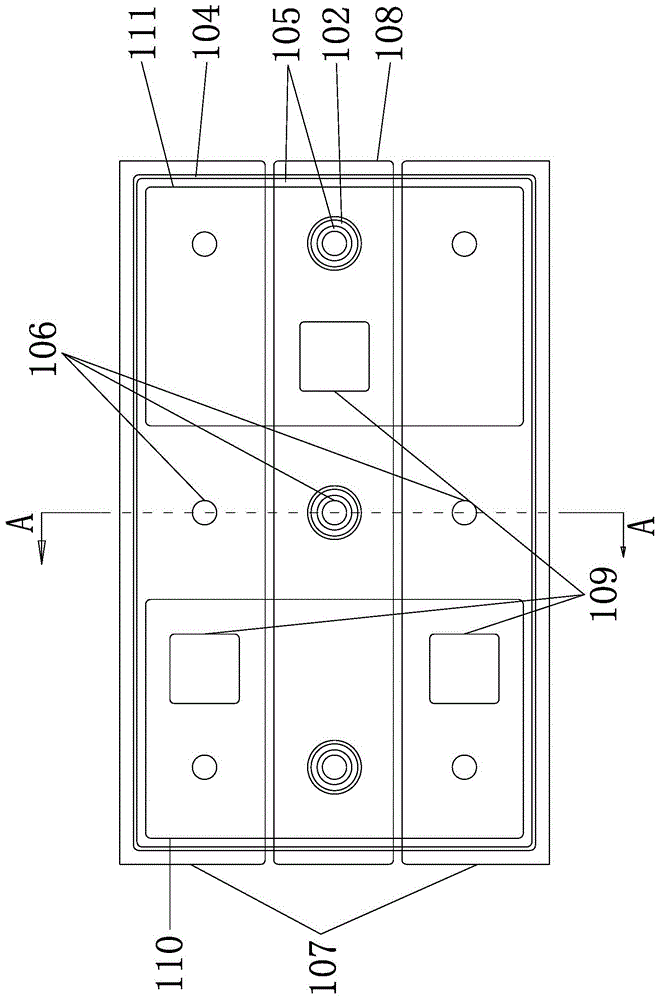

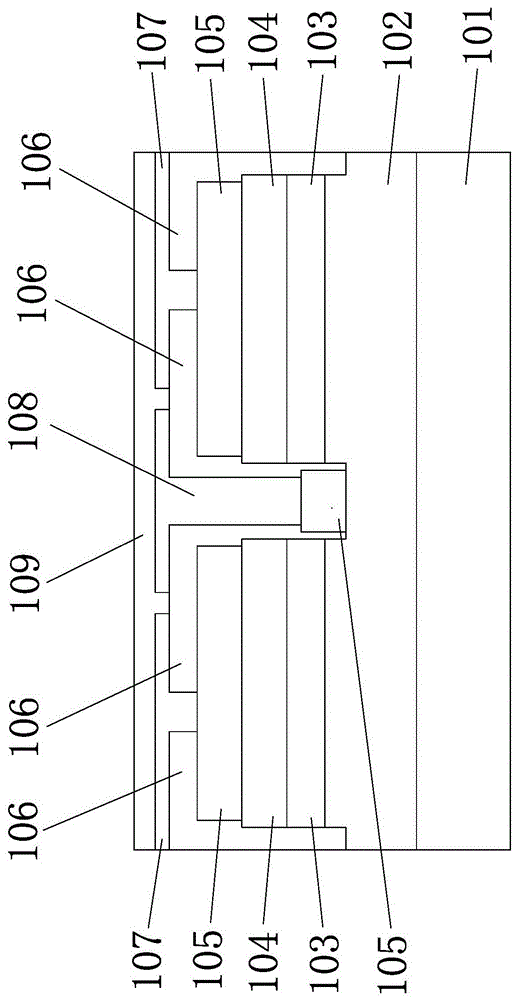

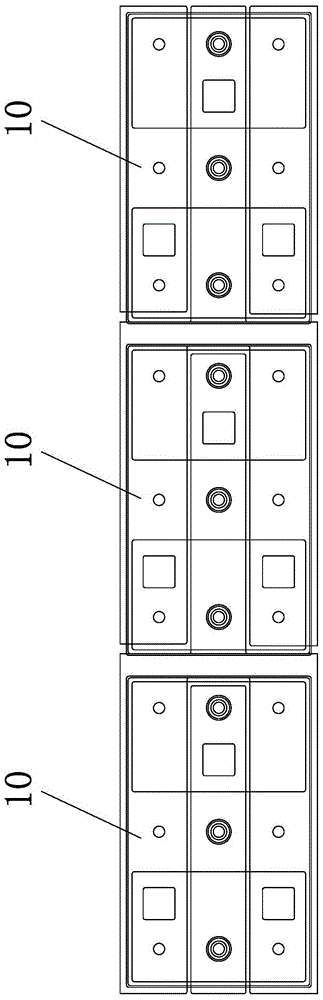

[0029] Such as Figure 1-2 Shown is a flip-chip light-emitting diode 10 with an ODR structure disclosed in the present invention, which mainly includes a substrate 101, an N-type layer 102, an active layer 103, a P-type layer 104, a current spreading layer 105, a DBR layer 106 and Ag reflective layer.

[0030] The N-type layer 102, the active layer 103 and the P-type layer 104 are sequentially arranged on the substrate 101, and the P-type layer 104 and the active layer 103 are etched to form steps to expose part of the N-type layer 102, the P-type layer 104 and the exposed A current spreading layer 105 is formed on the N-type layer 102 .

[0031] A DBR layer 106 is formed on the current spreading layer 105 , the DBR layer 106 is etched to expose a part of the current spreading layer 105 , and an Ag reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com