Functional fermented soybean milk and preparation method and application thereof

A functional, soymilk technology, applied in the directions of bacteria, applications, and dairy products used in food preparation, can solve the problem of not finding xanthine oxidase fermented soymilk, etc., and achieve good curdling effect, strong acid-producing ability, and good Effects of uric acid lowering and blood pressure lowering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of plantarum lactobacillus freeze-dried bacterial powder

[0029] 1) In a sterile operating bench, pick a small amount of bacterial liquid from the glycerol tube of Lactobacillus plantarum X7021, streak it on the MRS solid plate, culture it at 37°C for 36-48 hours, pick a single colony from the MRS solid plate and inoculate it on In the MRS medium, cultured anaerobically at 37°C for 18h, then inoculated in a fermenter containing MRS medium, anaerobically fermented for 24h, and then centrifuged at 6000rpm for 10 minutes to collect the bacteria, and use a sterile pH value of 6.4 Wash twice with phosphate buffer, and centrifuge again to obtain the sludge.

[0030] 2) Fully mix and emulsify the bacteria slime prepared in step 1) and the sterilized lyoprotectant at a weight ratio of 1:2 to obtain an emulsified mixture.

[0031] 3) The emulsified mixture prepared in step 2) was pre-frozen at -45°C for more than 4 hours, and then put into a fre...

Embodiment 2

[0034] Embodiment 2: the preparation of soybean milk raw material

[0035] Non-transgenic soybeans were beaten to make soymilk, boiled and sterilized in a boiling water bath at 100° C. for 30 minutes, and sterilized soymilk was prepared and set aside.

[0036] The preparation process of soybean milk is as follows: select non-genetically modified soybeans → wash → soak overnight in distilled water according to soybean: water = 1:3 (volume ratio) → add a certain volume of hot water at 85°C for thermal grinding → filter with gauze → boil for 30 minutes → cool down.

Embodiment 3-5

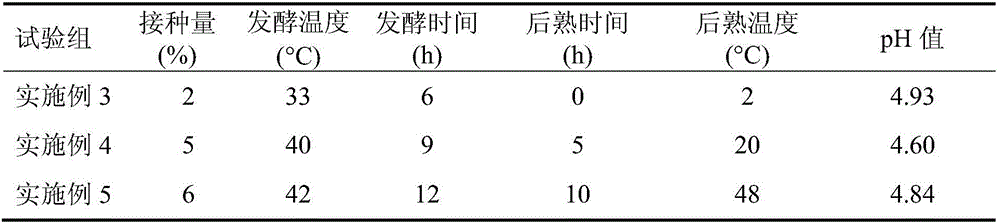

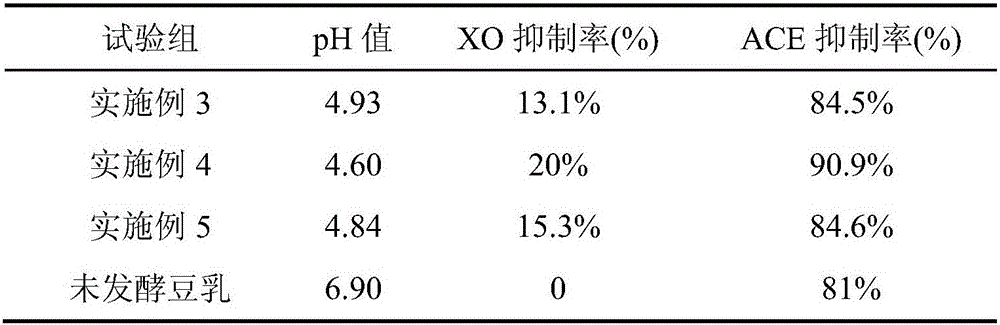

[0037] Example 3-5: Lactobacillus plantarum is used to prepare functional fermented soybean milk

[0038] The preparation method of functional soybean milk is as follows:

[0039] 1) The freeze-dried powder of Lactobacillus plantarum X7021 prepared in Example 1 was taken out and thawed, inoculated into sterilized MRS medium at a volume ratio of 2%, and cultured at 37°C and 200rpm until entering the logarithmic growth phase Take it out to obtain the activated bacteria liquid.

[0040] 2) Inoculate the activated bacteria solution in step 1) into the sterilized soybean milk prepared in Example 2 according to the volume ratio of 2-6%, and ferment in a constant temperature incubator at 33-42°C for 6-12h, at 0-10°C Post-ripening under conditions for 2-48 hours to obtain functional soybean milk.

[0041] 3) Detect the pH value of the functional soybean milk at the end of fermentation.

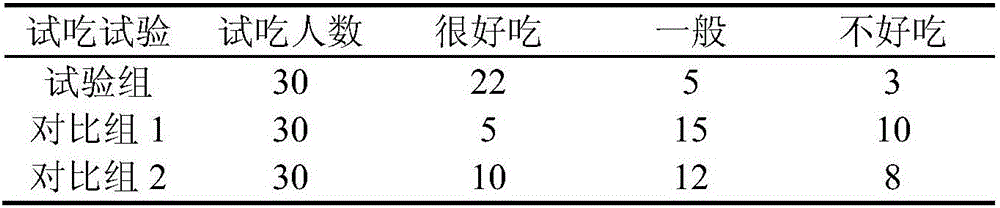

[0042] It was observed that the prepared functional soybean milk curd was in good condition. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com