Azeotrope separation process

An azeotrope and process technology, applied in the field of azeotrope separation and purification, can solve the problems of high investment and operating costs, large number of theoretical plates and reflux ratio, etc., and achieve high recovery rate, low pollution, and high product purity. Effect

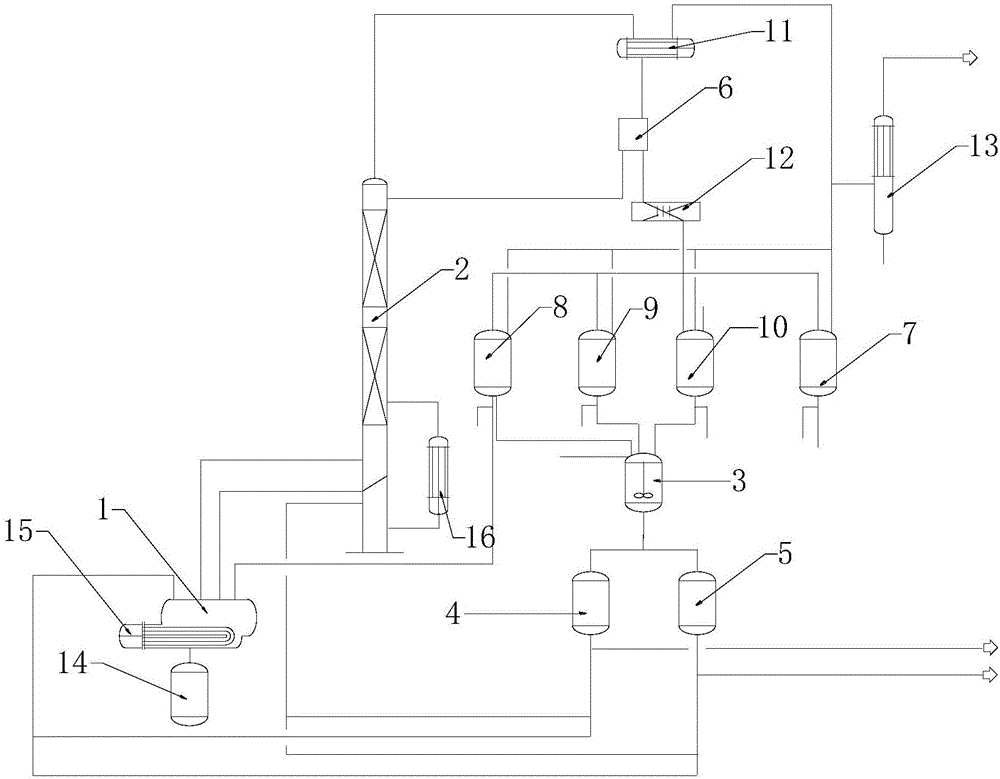

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw materials after pretreatment are mainly acetonitrile, water

[0027] The raw material first enters the extraction kettle 3, then adds the extractant, starts to stir for a certain period of time, and then stands still to separate the phases, and the water phase is extracted to the wastewater treatment section; the oil phase is transferred to the rectification kettle 1, and passes through the rectification kettle reboiler 15 After heating, the vapor phase rises into the rectifying tower 2, and is condensed by the tower top condenser 11. After the total reflux at the top of the tower is stable, according to the analysis results of the tower top product, a suitable reflux ratio is set, and the front fraction (extractant) is first extracted. The azeotrope with water, the transition fraction of extractant and acetonitrile), as the extractant can be recycled with the next batch of return to the extraction tank; then the acetonitrile product is extracted to the product r...

Embodiment 2

[0029] The raw materials after pretreatment are mainly dichloromethane and methanol

[0030] The raw material first enters the extraction kettle 3, then adds the extractant, starts to stir for a certain period of time, and then stands for phase separation. After the phase separation, an oil phase (dichloromethane product) and an aqueous phase (aqueous methanol solution containing a small amount of dichloromethane) are obtained. The water phase (aqueous methanol solution containing a small amount of dichloromethane) is transferred to the rectifying still 1, and after being heated by the rectifying still reboiler 15, the vapor phase rises into the rectifying tower 2 and is condensed by the overhead condenser 11. After the total reflux at the top of the tower is stable, an appropriate reflux ratio is set according to the analysis results of the top product, and the former fraction (dichloromethane / methanol / water), methanol, and water are sequentially extracted; water can be recycl...

Embodiment 3

[0032] The raw materials after pretreatment are mainly toluene and methanol

[0033] Through the extraction kettle 3, liquid-liquid extraction is carried out, and after phase separation, the toluene product is obtained; the water phase is the methanol aqueous solution and transferred to the rectification kettle 1, and after being heated by the rectification kettle reboiler 15, the vapor phase rises to the rectification tower 2 Inside, through the tower top condenser 11 condensation, after the total reflux at the top of the tower is stable, according to the analysis result of the tower top product, a suitable reflux ratio is set, and a small amount of front cut, methanol product, and transition cut (methanol and water) are successively extracted; After methanol is not contained in the distillation tower 2 overhead distillate, the heating can be stopped. The process wastewater in the kettle can be used as the extractant circulating water of this process after cooling.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com