A technological process for flue gas desulfurization transformation of coke oven without continuous furnace

A process flow and coke oven technology, which is applied in the field of coke oven flue gas desulfurization reformation, can solve the problems of furnace shutdown and the difficulty of reforming the flue gas emission system, and achieve the effects of high reliability, ingenious structural design of accessories, and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

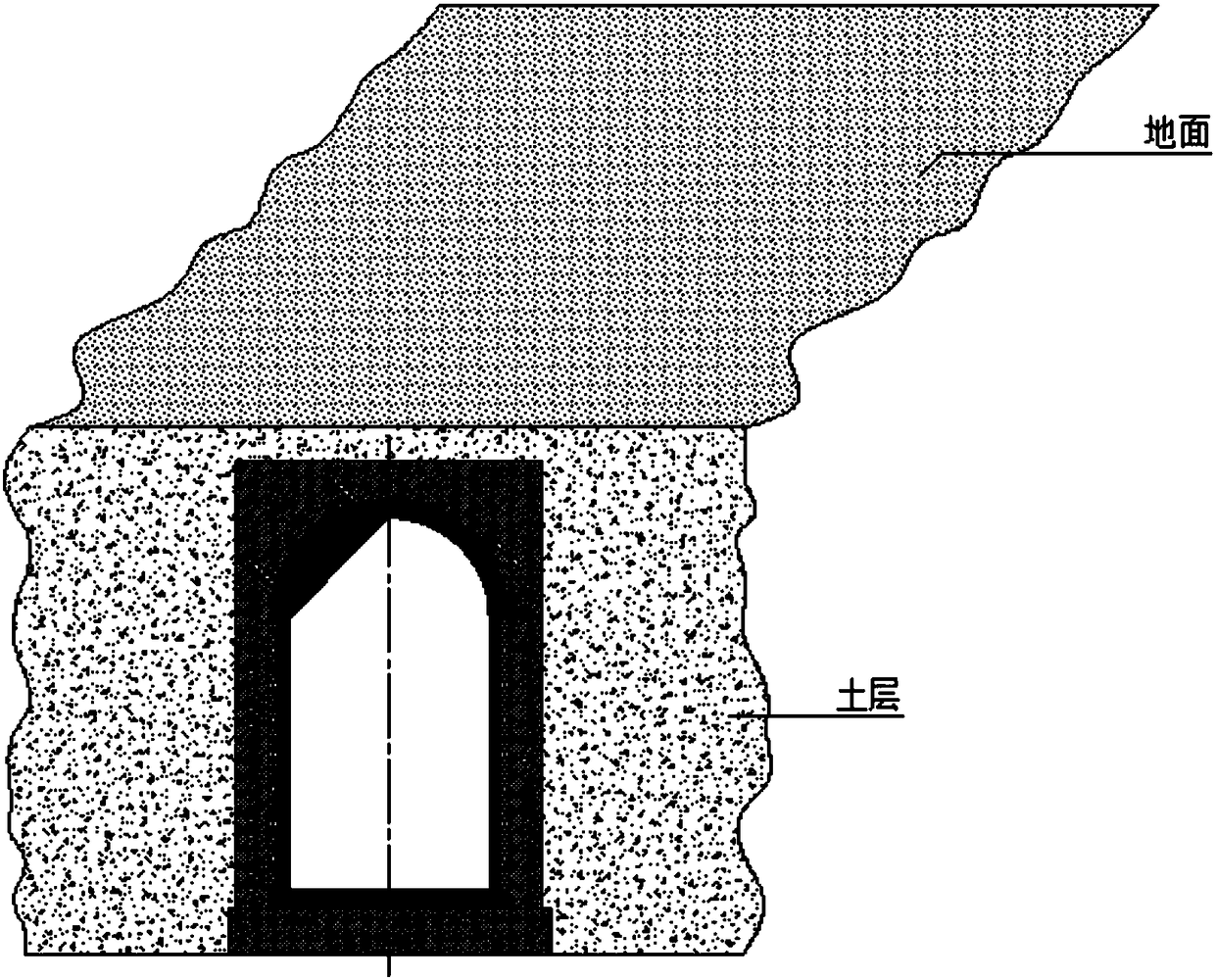

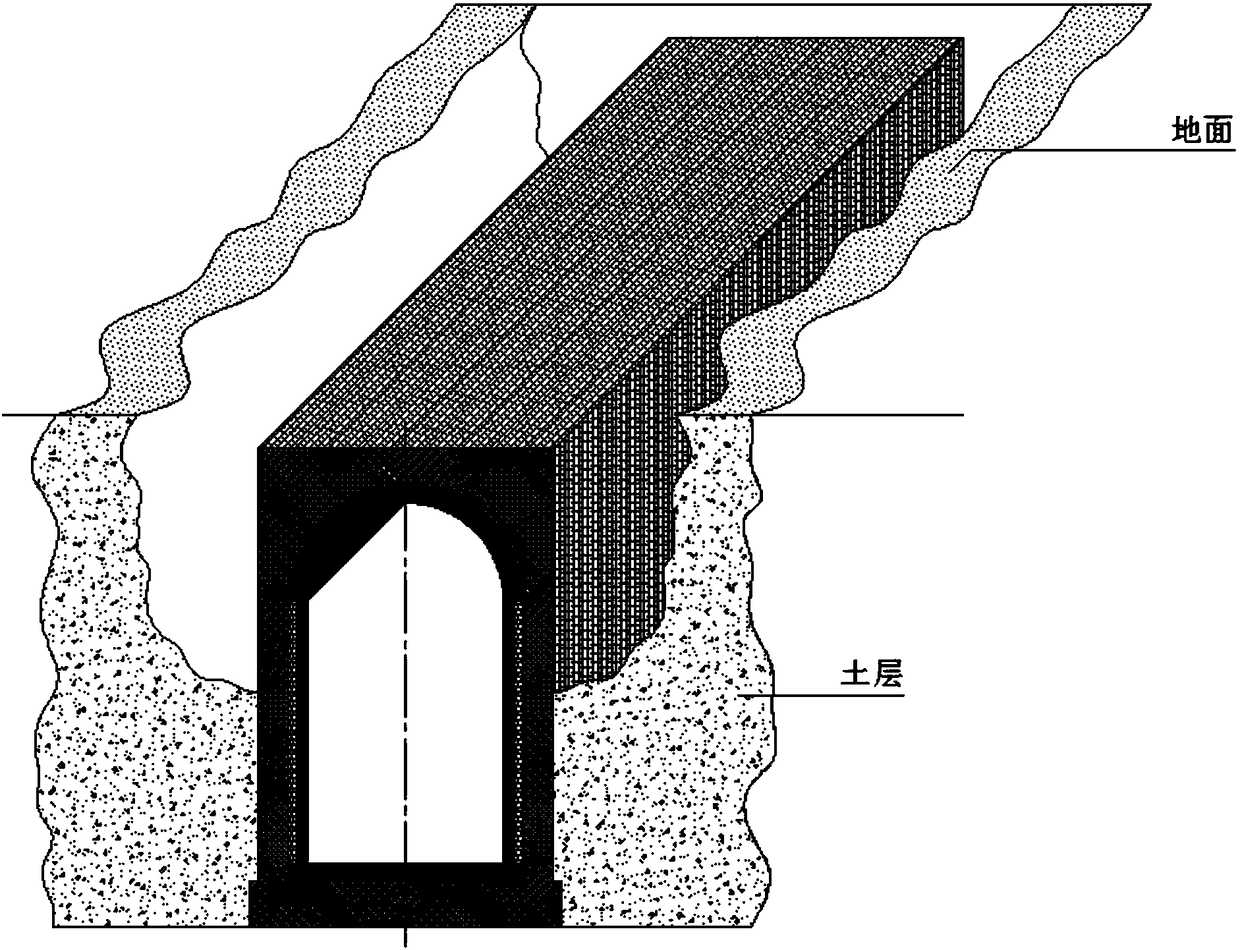

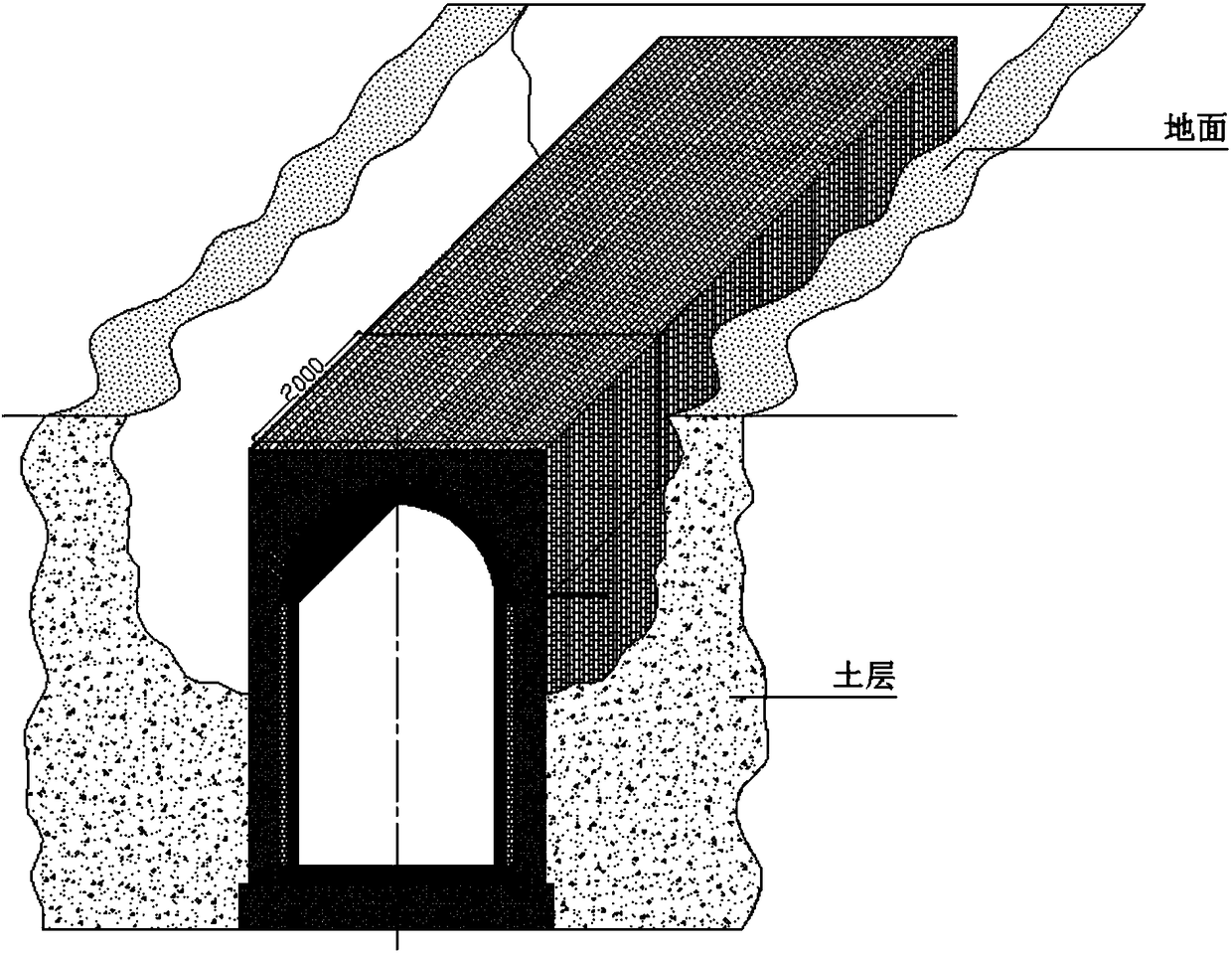

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0045] The main machinery and tools include: one 25-ton car crane; four 20-ton hydraulic jacks; four grinders; one excavator; one transport vehicle; one large concrete cutting machine; concrete drilling One machine; four chain hoists; several jacks and shovels; four electric welding machines; several lifting tools; two small submersible pumps; some scaffolding pipes and rainproof cloths; one small blower.

[0046] Construction preparation:

[0047] The technical information and drawings necessary for construction are complete; the equipment and tools required for construction are complete, and the measuring tools have been calibrated and are within the validity period; construction site conditions: laying out lines according to the size of the concrete flue and the size of the excavation; 'No impact in the construction area Other construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com