Slurry production line with real-time flow monitoring function

A real-time flow and production line technology, applied in the direction of dissolution, grain processing, mixer, etc., can solve the problems of uneven slurry, high dispersion cost, low solid content, etc., and achieve the effect of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

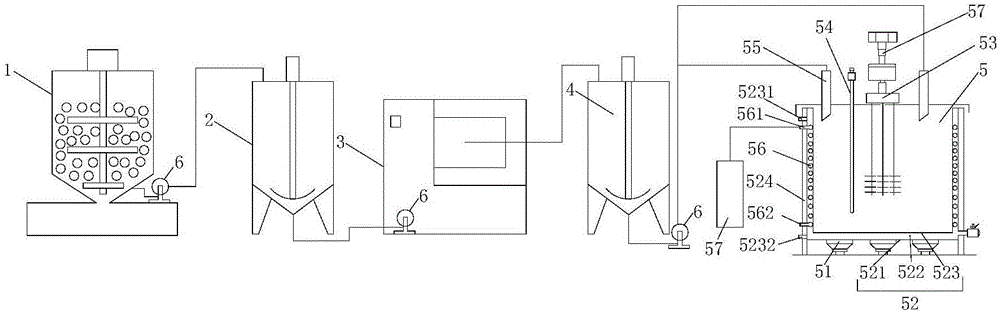

[0026] see figure 1 , figure 1 It is a structural schematic diagram of a slurry production line with real-time flow monitoring function of the present invention.

[0027] Such as figure 1 As shown, a slurry production line with real-time flow monitoring function includes a ball mill, a first transfer tank, a sand mill, a second transfer tank, an ultrasonic dispersion device and a central control system, and the outlet of the ball mill passes through the first The pipeline is connected to the feed port of the first transfer tank, the discharge port of the first transfer tank is connected to the feed port of the sand mill through the second pipeline, and the discharge port of the sand mill is passed through the third The pipeline is connected to the feed port of the second transfer tank, and the discharge port of the second transfer tank is connected to the ultrasonic dispersion device through the fourth pipeline, and the first pipeline, the second pipeline and the fourth pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com