Ferric oxide removing device for surface of steel plate

A removal device, iron oxide technology, applied in grinding/polishing safety devices, grinding machines, metal processing equipment, etc. The effect of recycling, reducing damage and increasing removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

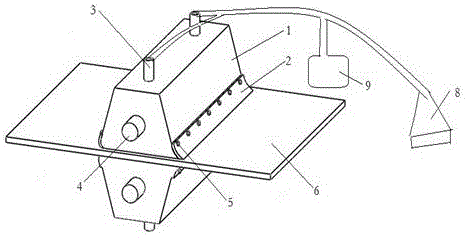

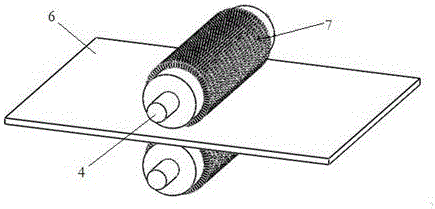

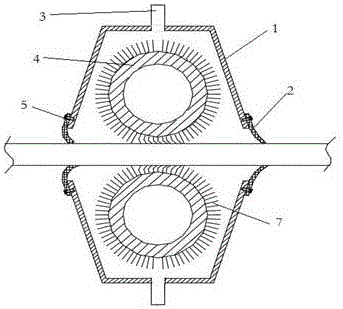

[0023] As shown in the figure: a device for removing iron oxide on the surface of a steel plate, comprising a negative pressure box 1 on a steel plate 6, a roller 4 inside the negative pressure box 1, and a metal wire on the surface of the roller 4, and the negative pressure box 1 is flexibly connected to The upper and lower surfaces of the steel plate 6, the negative pressure box 1 is symmetrically distributed relative to the steel plate 6, the bottom of the left and right sides of the negative pressure box 1 is fixedly connected with rubber baffles 2, and the top of the negative pressure box 1 has a negative pressure tube 3 , the negative pressure tube 3 communicates with the inside of the negative pressure box 1; the roller 4 runs through the front and back of the negative pressure box 1, and the metal wire is a flexible steel wire 7.

[0024] The above-mentioned negative pressure box 1 is connected to the steel plate 6, which is beneficial for the roller 4 in the negative p...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the front and rear sides of the negative pressure box 1 are triangular, and there is a negative pressure tube 3 on the top of the negative pressure box 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap