Method for treating industrial park dyeing waste water by adopting modified attapulgite

A technology for modifying attapulgite and printing and dyeing wastewater, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low level of ATP development and utilization, and achieve improved sludge Settling performance, enhanced overall stability, and improved COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

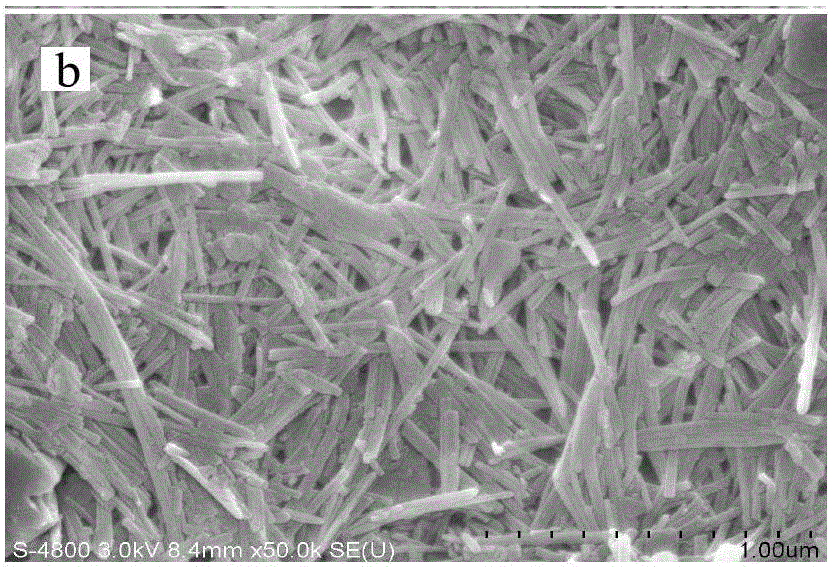

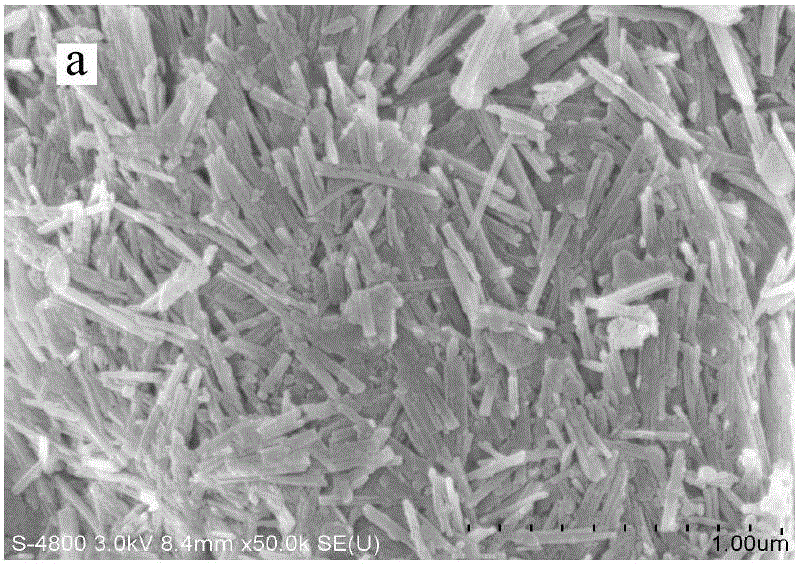

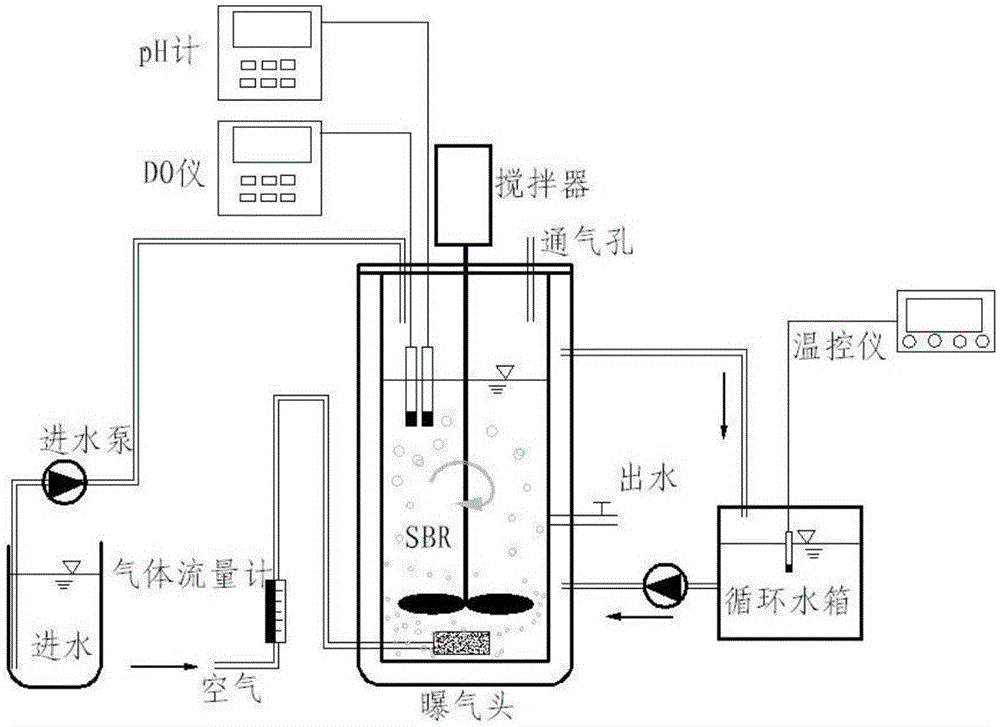

[0034] A sewage treatment plant in a township printing and dyeing industrial park in Huzhou, Zhejiang, in which printing and dyeing wastewater accounted for 70%, domestic sewage accounted for 20%, and other sewage accounted for 10%. The effluent of the hydrolytic acidification tank was used as the experimental object, and the COD concentration of the influent water quality was 200-300mg / L , the chromaticity is about 130 degrees, the pH is 7~8, and the ammonia nitrogen concentration is 8~15mg / L; the biological treatment process uses two identical SBR reactors R1 and R2 connected in parallel, and each experimental cycle is controlled by a time-controlled switch. 12h (including anaerobic stirring for 2h, aerobic aeration for 8h, precipitation for 1h, and standing for 1h), the aeration rate of the aeration head is 50L / h, the DO concentration control is about 4mg / L in the aerobic stage, and the DO concentration in the anaerobic stage The concentration control is about 0.2mg / L, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com