Stereoscopic structure organic semiconductor material and monomer preparation method

A technology of organic semiconductor and three-dimensional structure, which is applied in the fields of electricity and optics to achieve the effect of simple and convenient preparation process, simple preparation and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

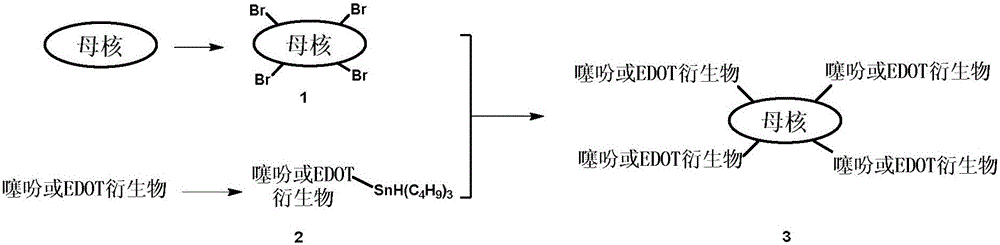

Method used

Image

Examples

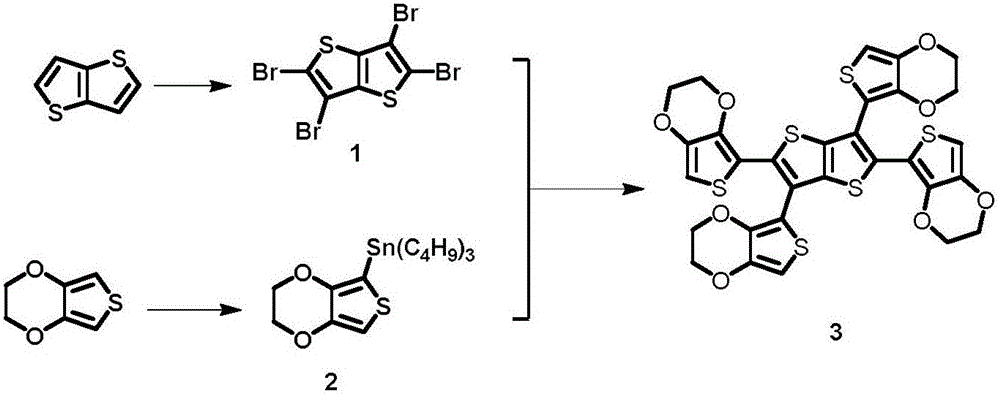

Embodiment 1

[0086] S1. Dissolve thiophene (5g, 35.7mmol) in a mixed solvent of glacial acetic acid (36ml) and chloroform (10ml), and add Br dropwise at room temperature 2 (28.5g, 180.56mmol), continue to stir for half an hour, and then heat and reflux overnight at 78°C; after cooling to room temperature, wash with water to precipitate a white solid compound, wash with water and methanol three times, and dry under vacuum at room temperature , to obtain white solid compound 1, [M+]=455.0. (yield: 95%);

[0087] S2, under the low temperature condition of -78 ℃, add n-BuLi (31.25ml) in the THF (150ml) solvent of EDOT (7.1g, 50mmol), stir at room temperature for 1.5 hours; Add ClSn (C 4 h 9 ) 3(50mmol, 13.56ml), reacted overnight at room temperature; quenched by adding saturated ammonium chloride solution, extracted with dichloromethane, and combined the organic phase; the organic phase was washed 3 times with water, dried over anhydrous magnesium sulfate, and spin-dried Distillation; Obtai...

Embodiment 2

[0090] The electrochemical polymerization process of monomer compound t-EDOT-TT is as follows:

[0091] In the electrodeposition process, the monomer compound t-EDOT-TT is first added to anhydrous dichloromethane solution to prepare a 0.56mM saturated solution, and then the electrolyte TBAPF is added to the solution 6 , so that the solution concentration is 0.1M. Using platinum wire as the counter electrode, ITO transparent glass as the working electrode, and silver wire as the reference electrode, the three-electrode system adopts cyclic voltammetry electropolymerization, and the voltage will be 100mV / s in the range of (-1.3V to +1.3V). The conductive polymer thin film deposited under the scan speed of 1 is marked as P(t-EDOT-TT)-1, and the conductive polymer thin film deposited under the same scan speed (-0.2V to 1.0V) is marked as P(t -EDOT-TT)-2;

Embodiment 3

[0093] The cyclic voltammetry scan of the monomer compound t-EDOT-TT is as follows:

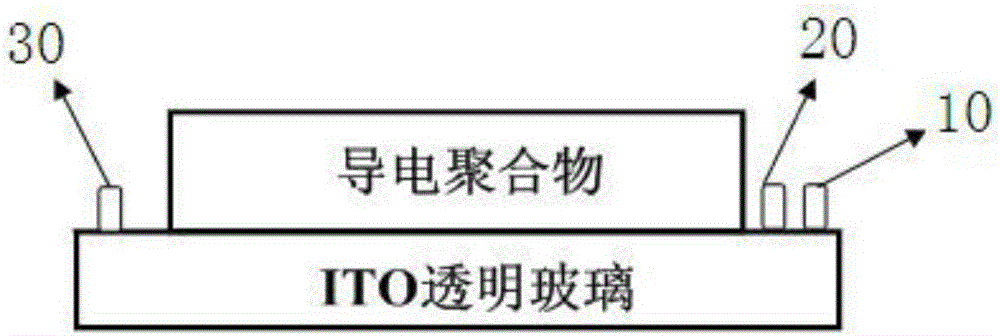

[0094] The platinum wire is used as the counter electrode, the ITO transparent glass is used as the working electrode, and the silver wire is used as the reference electrode. The film structure is as follows: image 3 Shown, wherein, 10 is a reference electrode, 20 is a counter electrode, and 30 is a working electrode; Cyclic voltammetry scanning obtains the cyclic voltammetry curves of two kinds of film polymers (i.e. conductive polymer films), as Figure 4a (corresponding to P(t-EDOT-TT)-1) and 4b (corresponding to P(t-EDOT-TT)-2); when the scanning speed is 100mV / s, P(t-EDOT-TT)-1 The starting point of oxidation is 0.26V, and the starting point of reduction is 0.094V. The oxidation onset of polymer P(t-EDOT-TT)-2 under the same conditions is 0.087V, and the reduction onset is -0.1V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com