Cd metal-organic framework material and preparation method and application thereof

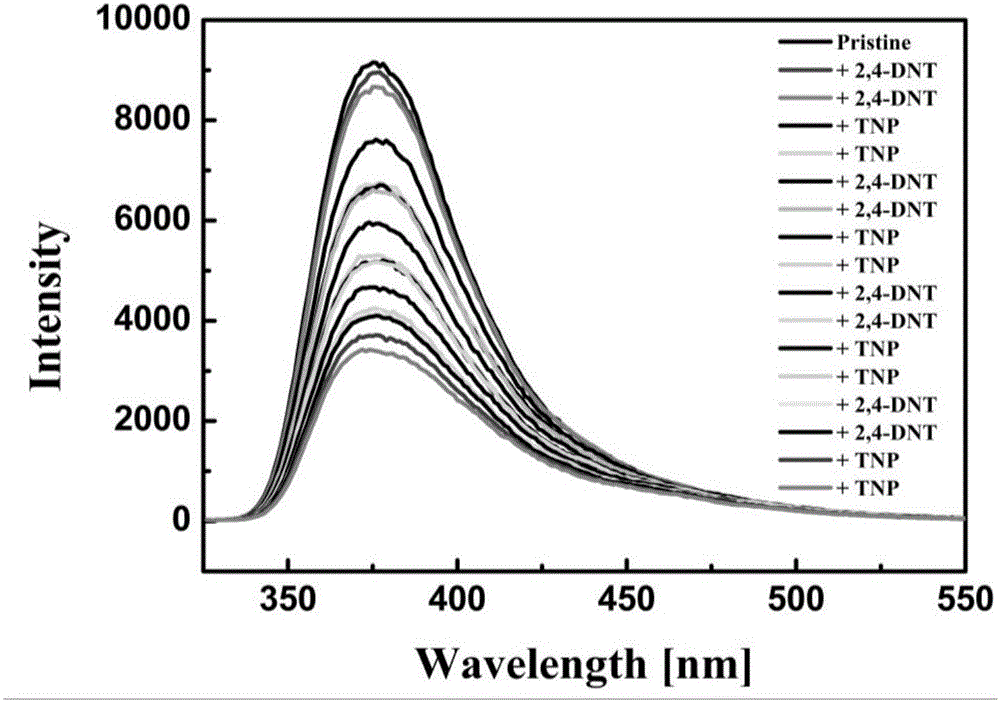

A metal-organic framework and organic ligand technology, used in the field of Cd metal-organic framework materials, metal-organic coordination polymer materials, and preparation fields, can solve problems such as reduction and strong radiation, and achieve simple process, strong fluorescence, and yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

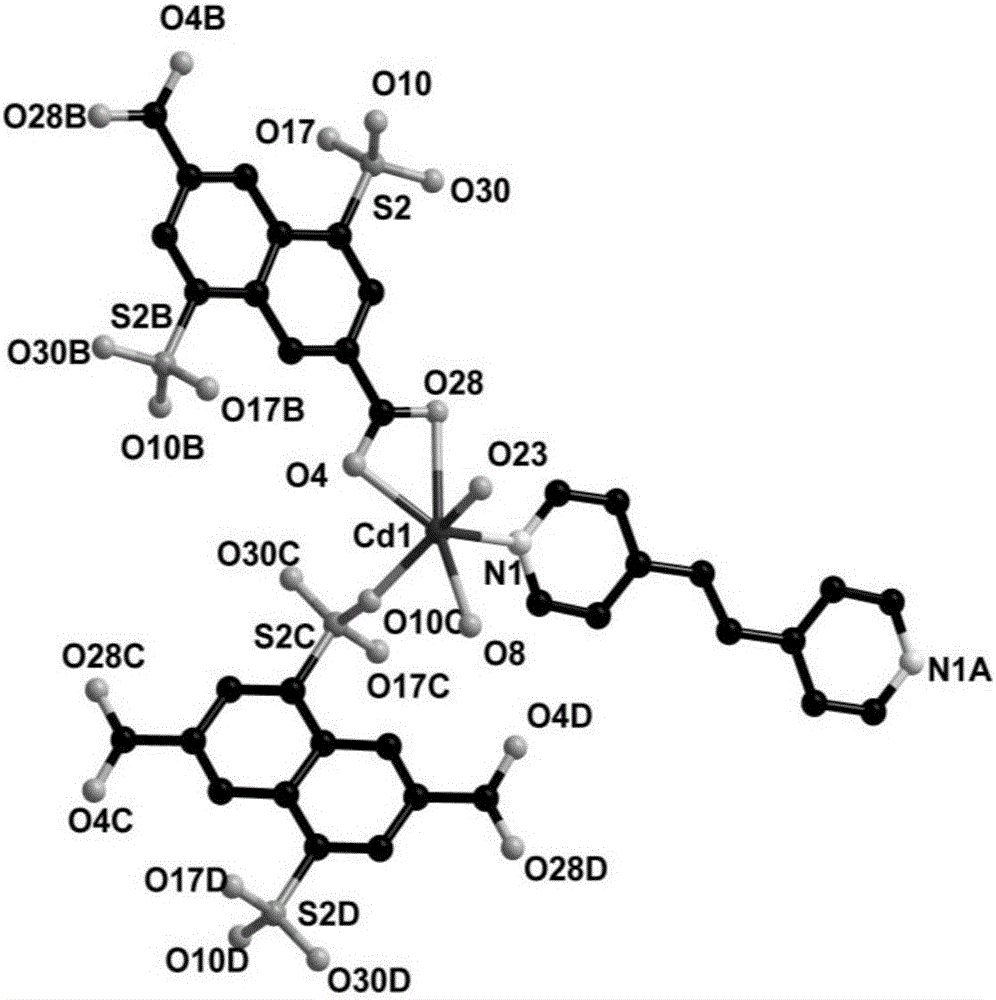

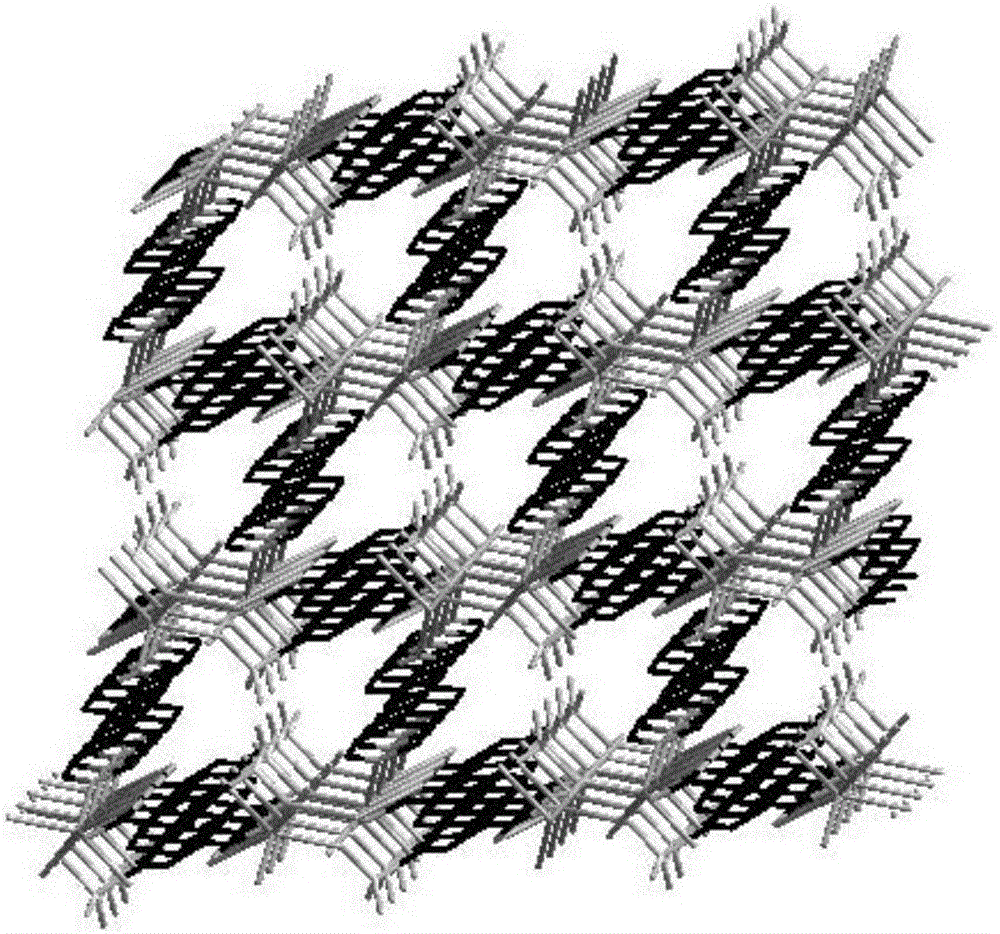

Method used

Image

Examples

Embodiment 1

[0020] Mix organic ligand L (0.035 mmol), auxiliary ligand dpe (0.035 mmol) and cadmium nitrate tetrahydrate (0.035 mmol) in 1 mL of N,N-dimethylacetamide, add 0.1 mL of H 2 O, sealed in a vial. Crystals of MOFs were obtained via thermal reaction at 80 °C for 24 hours.

Embodiment 2

[0022] Mix organic ligand L (0.035 mmol), auxiliary ligand dpe (0.019 mmol) and cadmium nitrate tetrahydrate (0.035 mmol) in 1 mL of N,N-dimethylacetamide, add 0.5 mL of H 2 O, sealed in a vial. Crystals of MOFs were obtained via thermal reaction at 80 °C for 48 hours.

Embodiment 3

[0024] Mix organic ligand L (0.019 mmol), auxiliary ligand dpe (0.035 mmol) and cadmium nitrate tetrahydrate (0.035 mmol) in 1.5 mL of N,N-dimethylacetamide, add 0.5 mL h 2 O, sealed in a vial. Crystals of MOFs were obtained via thermal reaction at 80 °C for 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com