Surface crystallization ceramization environment-friendly fire retardant for electric wires and cables and preparation method thereof

A wire and cable, flame retardant technology, applied in the field of polymer materials, to achieve the effect of delaying escape time, good stability, and improving processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

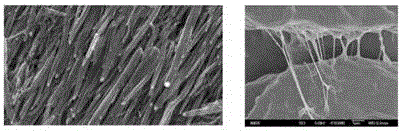

Image

Examples

Embodiment 1

[0027] The mass parts of raw materials are: PVC 100 parts, SiO 2 55 servings; Al 2 O 3 20 servings; Fe 2 O 3 0.5 part; CaO1 part; MgO0.1 part; Na 2 O 1.5 servings; K 2 1.5 parts of O; 10 parts of low-temperature ceramization aid; 3 parts of lubricant; 2 parts of surface treatment agent.

[0028] According to a certain ratio, add SiO in turn 2 , Al2O 3 , Fe 2 O 3 , CaO, MgO, Na 2 O, K 2 O. The low-temperature ceramization aid is placed in a rapid mixer, the temperature is raised to 120° C., and the reaction is carried out for 120 minutes, and then 3 parts of lubricant and 2 parts of surface treatment agent are added to obtain the surface crystalline ceramization and environmental protection flame retardant for wire and cable.

[0029] The PVC and the flame retardant are added to the high-speed mixer and mixed evenly according to the proportion, and then the material strip is extruded from the die head with a twin-screw extruder. After drying, injection molding was p...

Embodiment 2

[0035] The mass parts of raw materials are: PVC 100 parts, SiO 2 70 servings; Al 2 O 3 30 servings; Fe 2 O 3 0.5 part; CaO 1 part; MgO 0.1 part; Na 2 O 1.5 servings; K 2 12 parts of O; 20 parts of low temperature ceramization aid; 5 parts of lubricant; 4 parts of surface treatment agent.

[0036] According to a certain ratio, add SiO in turn 2 , Al 2 O 3 , Fe 2 O 3 , CaO, MgO, Na 2 O, K 2 O. The low-temperature ceramization aid is placed in a rapid mixer, the temperature is raised to 120° C., and the reaction is performed for 120 minutes. Then, 5 parts of lubricant and 4 parts of surface treatment agent are added to obtain the surface crystalline ceramization and environmental protection flame retardant for wire and cable.

[0037] The PVC and the flame retardant are added to the high-speed mixer and mixed evenly according to the proportion, and then the material strip is extruded from the die head with a twin-screw extruder. After drying, injection molding was ...

Embodiment 3

[0043] The mass parts of raw materials are: PVC 100 parts, SiO 2 60 servings; Al 2 O 3 30 servings; Fe 2 O 3 0.5 part; CaO 2 parts; MgO 0.1 part; Na 2 O 1.5 servings; K 2 12 parts of O; 20 parts of low-temperature ceramicizing aid; 5 parts of lubricant; 8 parts of surface treatment agent.

[0044] According to a certain ratio, add SiO in turn 2 , Al 2 O 3 , Fe 2 O 3 , CaO, MgO, Na 2 O, K 2 O. The low-temperature ceramization aid is placed in a rapid mixer, the temperature is raised to 120° C., and the reaction is carried out for 120 minutes. Then, 5 parts of lubricant and 8 parts of surface treatment agent are added to obtain the surface crystalline ceramization and environmental protection flame retardant for wire and cable.

[0045] The PVC and the flame retardant are added to the high-speed mixer and mixed evenly according to the proportion, and then the material strip is extruded from the die head with a twin-screw extruder. After drying, injection molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com