New Renewable Energy Fuel Pellets And It's Manufacturing Process

A technology of renewable energy and fuel particles, applied in the direction of biofuels, fuels, solid fuels, etc., to achieve high calorific value and solve existing environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

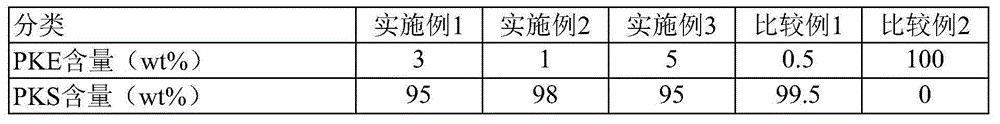

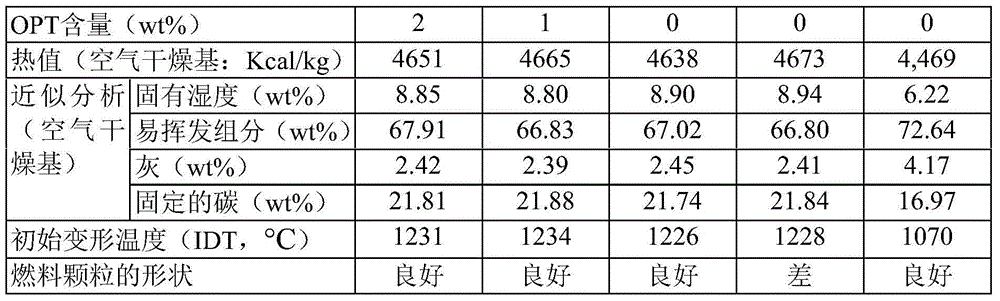

Embodiment 1

[0063] A mixture was prepared by mixing 3% by weight of palm kernel shell (PKE) powder, 95% by weight of palm kernel shell (PKS) powder and 2% by weight of oil palm trunk (OPT) powder.

[0064] Palm kernel residue is a powder having a moisture content of 6.22% by weight and an oil content of 8% by weight, and is used by grinding it to have an average particle size of 100 mesh to 200 mesh. Palm kernel shell powder comprising a moisture content of 8.98% by weight was used with an average particle size of 100 mesh to 200 mesh by milling. And, by pulverizing, an oil palm trunk containing a moisture content of 9% by weight was used with an average particle size of 100 mesh to 200 mesh.

[0065] Pressed at 750 tons / m by using hydraulic oil 2 The resulting mixture was subjected to compression molding to produce fuel pellets.

Embodiment 2

[0067] Fuel pellets were manufactured in the same manner as in Example 1 except using a mixture containing 5% by weight of palm kernel pomace, 90% by weight of palm kernel shell, and 5% by weight of oil palm trunk.

Embodiment 3

[0069] Fuel pellets were produced in the same manner as in Example 1 except using a mixture containing 5% by weight of palm kernel pomace and 95% by weight of palm kernel shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com