An economical wear-resistant and corrosion-resistant iron container and its preparation method

An economical, container-based technology, applied in coatings, metal material coating processes, solid-state diffusion coatings, etc., can solve problems such as wear and corrosion of iron containers, and achieve good corrosion resistance, low carbon content and impurity content Low, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below:

[0036] Table 1 is the value list of the chemical composition implemented in the present invention;

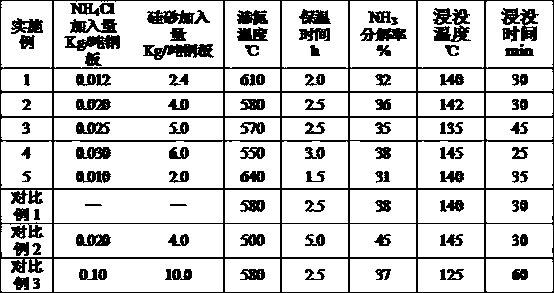

[0037] Table 2 is the value list of each embodiment of the present invention and the main process of comparative examples;

[0038] Table 3 is a list of performance test results of various embodiments of the present invention and comparative examples.

[0039] Each embodiment of the present invention is produced according to the following steps:

[0040] 1) Process the base of the low carbon steel plate into a workpiece with the required container shape;

[0041] 2) Grind and clean the inside and outside of the workpiece;

[0042] 3) Nitriding the workpiece: add NH to the nitriding container 4 Cl and silica sand, and stir well; of which: NH 4 Cl is added at 0.01~0.03Kg / ton steel plate, silica sand is added at 2~6Kg / ton steel plate, NH 4 The ratio of Cl to silica sand is 1:200; put the workpiece into the gas nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com