A kind of high-strength alloy structural steel and its preparation method

A high-strength alloy and structural steel technology, applied in the field of alloy steel, can solve the problems of unstable steel plate strength, toughness performance, difficult internal quality to meet customer needs, affecting yield strength, tensile strength, etc., and achieves stable and good performance indicators. The effect of eliminating mixed crystal phenomenon and improving tensile and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

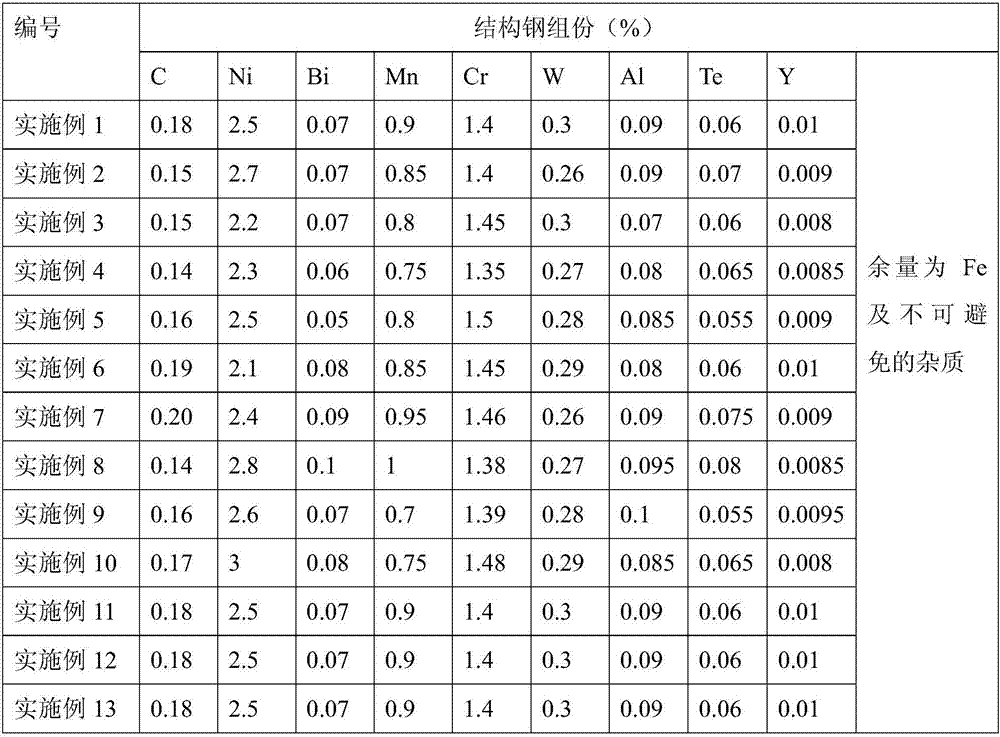

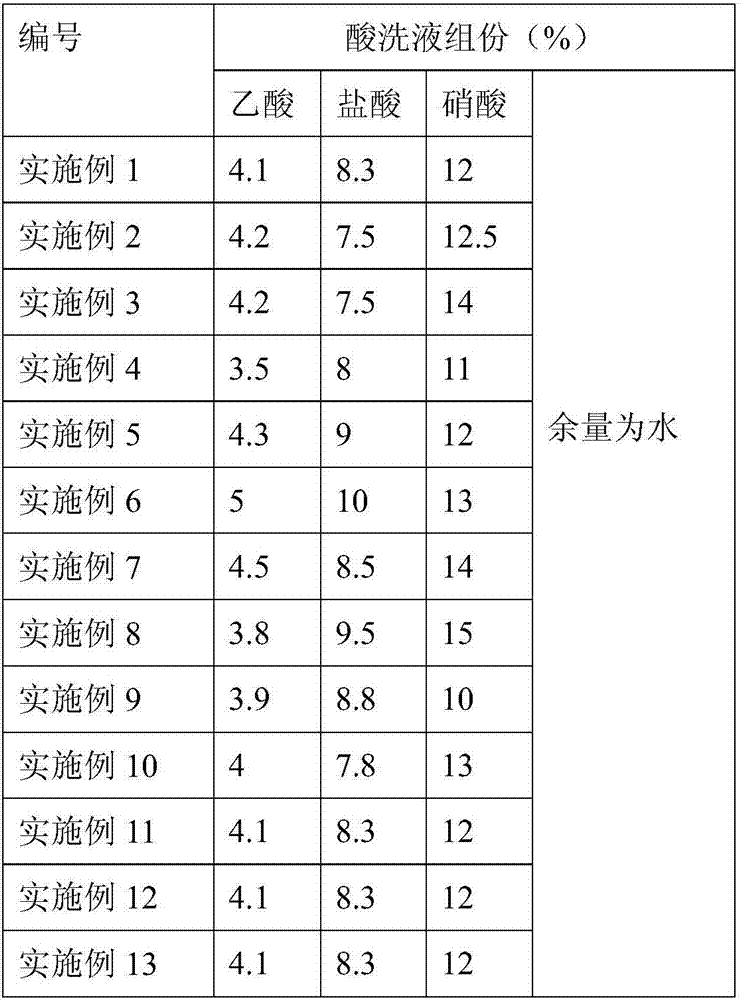

Examples

Embodiment 1

[0037] A preparation method of high-strength alloy structural steel, said preparation method comprising the following steps:

[0038] 1) Smelting, refining and continuous casting into billets;

[0039] 2) soaking the casting slab, the thickness of the casting slab is 80mm;

[0040] 3) Forging: at 970°C and a forging pressure of 6.4MPa, forge the slab after soaking in step 2) to extend it by 8%;

[0041] 4) Primary rolling: at 320°C and 6100KN rolling force, roll the forged product in step 3) at a speed of 6.5mm / s, the rolling direction and the forging direction in step 3) are perpendicular to each other, and the rolling pass for one time;

[0042] 5) Secondary rolling: at 620°C and 3500KN, the product after step 4) is subjected to secondary rolling at 2.5mm / s, the angle between the direction of the secondary rolling and the rolling direction of step 4) is 18°, and the rolling pass is one time;

[0043] 6) Three times of rolling: the product after the second rolling in step...

Embodiment 2

[0048] A preparation method of high-strength alloy structural steel, said preparation method comprising the following steps:

[0049] 1) Smelting, refining and continuous casting into billets;

[0050] 2) soaking the casting slab, the thickness of the casting slab is 80mm;

[0051] 3) Forging: at 975°C and 5.5MPa, forge the slab soaked in step 2) to extend it by 8%;

[0052] 4) Rolling: at 330°C and 6500KN, the product forged in step 3) is rolled at a speed of 6.8mm / s, the rolling direction is perpendicular to the forging direction of step 3), and the rolling pass is one;

[0053] 5) Secondary rolling: at 620°C and 3450KN, the product after step 4) is subjected to secondary rolling at 2.8mm / s, the angle between the direction of the secondary rolling and the rolling direction of step 4) is 16°, and the rolling pass is one time;

[0054] 6) Three times of rolling: the product after the second rolling in step 5) is placed in heat conduction oil and cooled to room temperature, ...

Embodiment 3

[0059] A preparation method of high-strength alloy structural steel, said preparation method comprising the following steps:

[0060] 1) Smelting, refining and continuous casting into billets;

[0061] 2) soaking the casting slab, the thickness of the casting slab is 80mm;

[0062] 3) Forging: at 970°C and 6.3MPa, forge the slab after soaking in step 2) to extend it by 7%;

[0063] 4) Rolling: at 330°C and 6150KN, the product forged in step 3) is rolled at a speed of 6.4mm / s, the rolling direction is perpendicular to the forging direction of step 3), and the rolling pass is one;

[0064] 5) Secondary rolling: at 620°C and 3300KN, the product after step 4) is subjected to secondary rolling at 2.7mm / s, the angle between the direction of the secondary rolling and the rolling direction of step 4) is 20°, and the rolling pass is one time;

[0065] 6) Three times of rolling: the product after the second rolling in step 5) is placed in heat-conducting oil and cooled to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com