Double-fuel machine control system and double-fuel machine control method igniting natural gas due to micro-injection of diesel oil

A control method and control system technology, applied in the field of diesel micro-injection ignited natural gas dual-fuel engine control system, can solve the problems of large speed fluctuation rate, slow response speed, natural gas leakage, etc., and achieve fast response speed, smooth transition, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing.

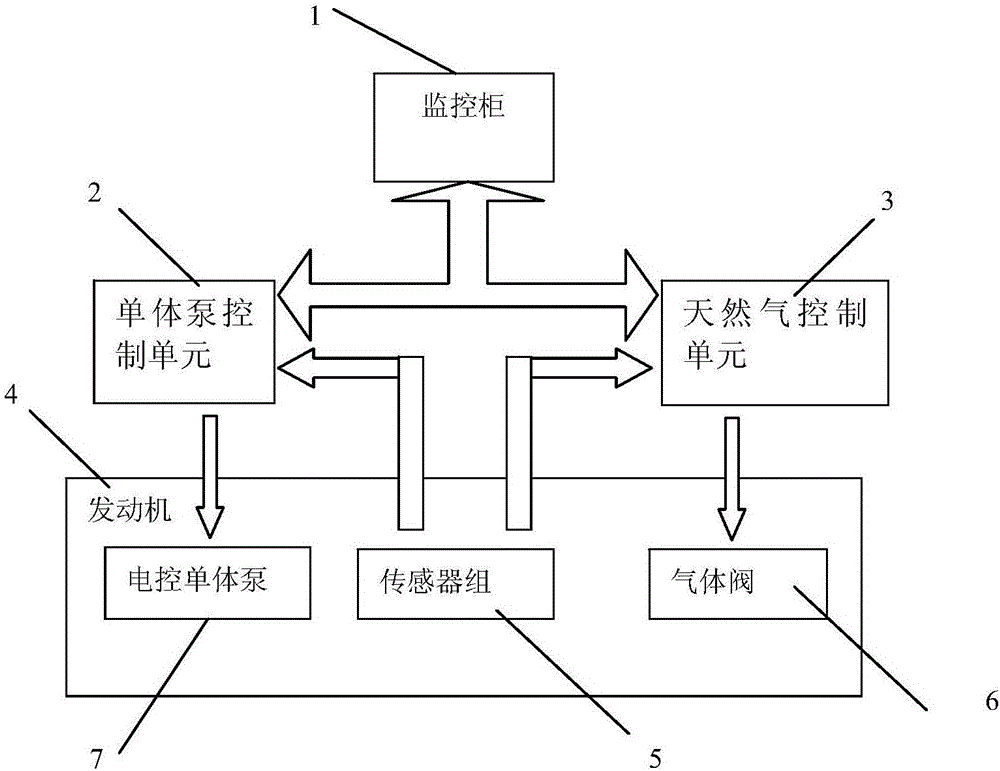

[0060] Such as figure 1The shown diesel micro-injection pilot natural gas dual-fuel engine control system includes a monitoring cabinet 1, a unit pump control unit 2, a natural gas control unit 3 and a sensor group 5.

[0061] The monitoring cabinet 1 has a human-computer interaction interface for displaying various monitoring information and sending operation instructions. The monitoring cabinet 1 is connected with the unit pump control unit 2 and the natural gas control unit 3 respectively. The operator sends a mode switching instruction on the human-computer interaction interface of the monitoring cabinet 1 .

[0062] The sensor group 5 sends the collected signals to the unit pump control unit 2 and the natural gas control unit 3 , and the sensor group 5 is connected to the unit pump control unit 2 and the natural gas control unit 3 respectively.

[0063] The unit pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com