Cleanliness detection method of rubber plugs for sterile powder for ultraviolet absorbance evaluative injection

A technology of sterile powder and detection method, applied in the measurement of color/spectral characteristics, etc., can solve the problems of long time period, complex rubber stopper composition, and high detection cost, and achieve the effect of saving cost and improving the accuracy and efficiency of research and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Ultraviolet absorbance of the present invention evaluates the detection method of the cleanliness of the rubber stopper for sterile powder for injection as follows:

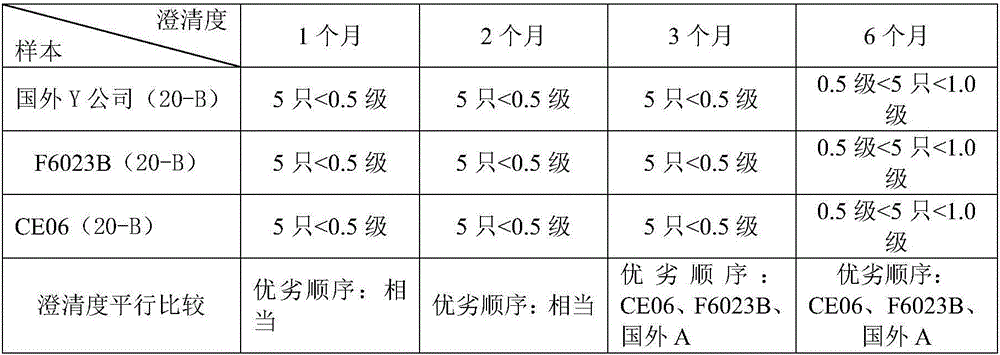

[0017] Select two basic production formulas to produce rubber stoppers for sterile powders for injection, product specification 20-B, carry out rapid evaluation according to the method of the present invention, and initially compare the cleanliness of the rubber stoppers; Sodium drug powder was accelerated for 6 months for compatibility test, and the key index of drug clarity was selected for comparison, so as to verify the effectiveness of the rapid test method. Based on the basic production formula, follow the conventional production process of rubber stopper for sterile powder for injection, such as compounding, rubber mixing, vulcanization, punching, cleaning and packaging, etc., and produce according to the corresponding process conditions.

[0018] The rubber stopper for sterile powder for injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com