Method for depositing nano-silver in microfluidic channels

A nano-silver, microfluidic technology, applied in chemical instruments and methods, laboratory containers, instruments, etc., can solve problems such as complex process conditions and the use of expensive instruments, and achieve good repeatability, low price, and repeatability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

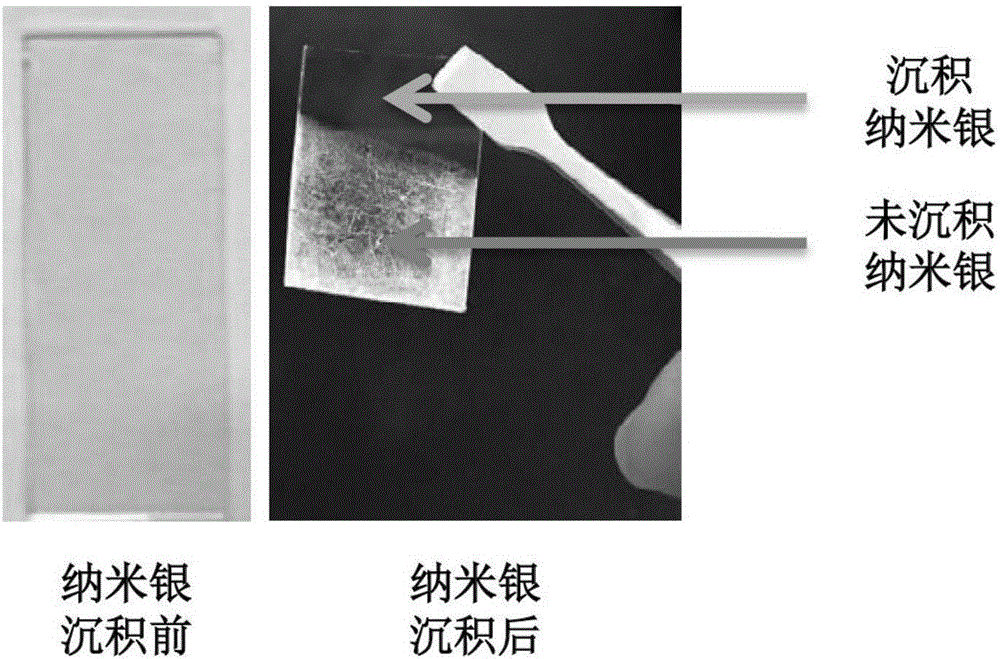

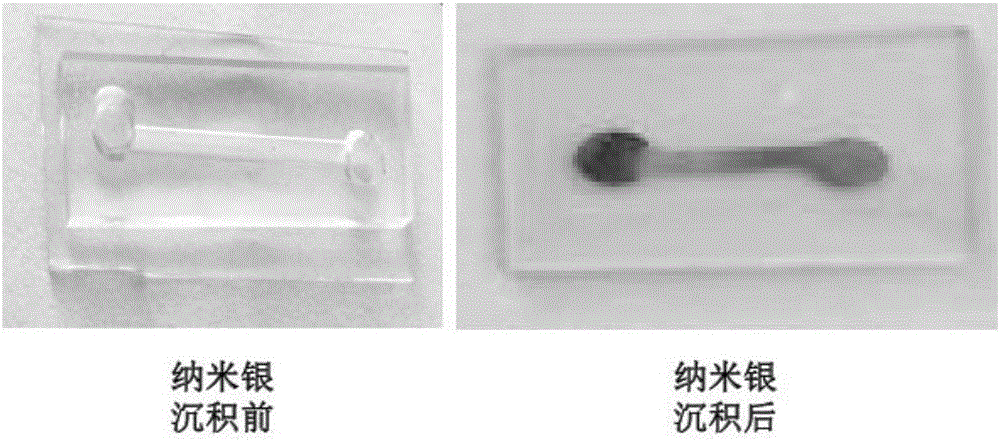

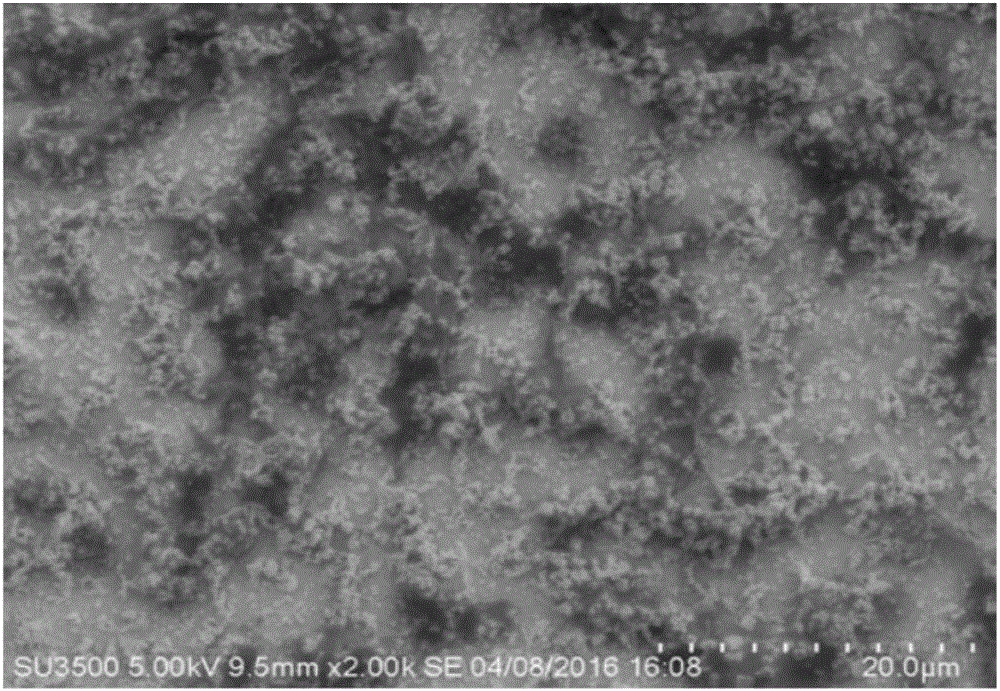

Image

Examples

Embodiment 1

[0021] (1) Pour PDMS liquid A (monomer) and liquid B (initiator) into a beaker at a mass ratio of 10:1, stir with a glass rod for 5 minutes, and then pour it into the above-mentioned petri dish with a silicon wafer.

[0022] (2) Put the petri dish in a concentrated desiccator, pump air with a diaphragm vacuum pump for 1.5 hours to remove air bubbles in PDMS, and then place it in a vacuum oven at 80° C. for 1 hour to solidify.

[0023] (3) After it cools naturally, gently peel off the PDMS from the silicon wafer template, cut it into small pieces with a cutting machine, and then punch holes in the corresponding parts with a manual chip puncher for experimental use.

[0024] (4) Ultrasonic clean the ITO glass with absolute ethanol, and then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 1 mg / mL PDDA solution for 5 minutes, and take it out , washed with distilled water several times in a small amount, an...

Embodiment 2

[0032] (1) Pour PDMS liquid A (monomer) and liquid B (initiator) into a beaker at a mass ratio of 10:1, stir with a glass rod for 5 minutes, and then pour it into the above-mentioned petri dish with a silicon wafer. The culture dish was placed in a concentrated desiccator, evacuated with a diaphragm vacuum pump for 1.5 hours to remove air bubbles in PDMS, and then placed in a vacuum oven at 80°C for 1 hour to solidify. After it cooled naturally, the PDMS was gently peeled off from the silicon wafer template, cut into small pieces with a cutting machine, and then punched holes in the corresponding parts with a manual chip puncher for experimental use.

[0033] (2) Ultrasonic clean the ITO glass with absolute ethanol, and then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 1 mg / mL PDDA solution for 5 minutes, and take it out , washed with distilled water several times in a small amount, and then blown d...

Embodiment 3

[0037] (1) Pour PDMS liquid A (monomer) and liquid B (initiator) into a beaker at a mass ratio of 10:1, stir with a glass rod for 5 minutes, and then pour it into the above-mentioned petri dish with a silicon wafer. The culture dish was placed in a concentrated desiccator, evacuated with a diaphragm vacuum pump for 1.5 hours to remove air bubbles in PDMS, and then placed in a vacuum oven at 80°C for 1 hour to solidify. After it cooled naturally, the PDMS was gently peeled off from the silicon wafer template, cut into small pieces with a cutting machine, and then punched holes in the corresponding parts with a manual chip puncher for experimental use.

[0038] (2) Ultrasonic clean the ITO glass with absolute ethanol, and then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 1 mg / mL PDDA solution for 5 minutes, and take it out , washed with distilled water several times in a small amount, and then blown d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com