Electric contact and manufacturing method therefor

A technology of electrical contacts and connecting circuits, which is applied in the field of composite materials, can solve the problems of placing electrical contacts upside down, etc., and achieve the effects of improving yield rate, wide selection of materials, and controllable costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

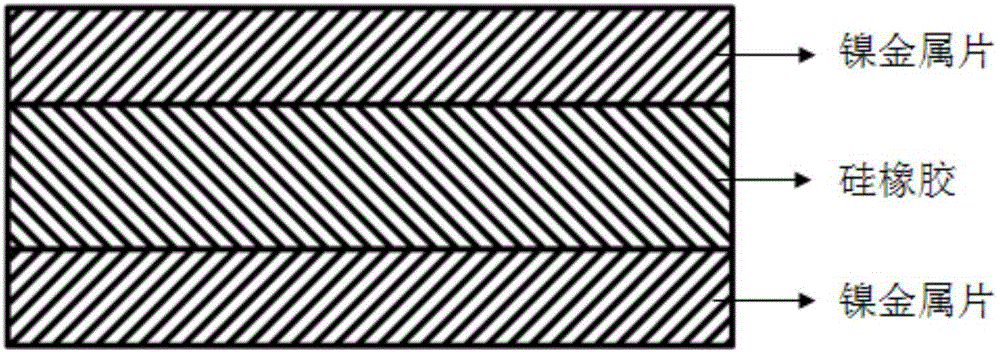

[0030]A bright 0.05mm thick vinyl tri-tert-butyl peroxysilane (VTPS) treated pure nickel sheet (nickel content greater than 99.5%), and silicone rubber compound (containing Dow Corning silicone rubber SE-4706U100 1 part, peroxide vulcanizing agent DCP 1 part) Pressing at 180 ℃ to make a composite sheet with a thickness of 0.5 mm, use instant adhesive or room temperature curing silicone rubber-metal adhesive to seal the rubber of this composite sheet The surface is bonded to a nickel metal sheet with a thickness of 0.05 mm to obtain a composite sheet of two layers of metal sheets and rubber. The obtained composite sheet was punched into small discs with a diameter of 5 mm. The material or chemical composition of the two circular surfaces of this small disc is the same, and the contact resistance of the two circular surfaces is also the same. This small disc, as an electrical contact, is compounded with silicone rubber by thermal vulcanization and bonding, so that a silicone ru...

Embodiment 2

[0032] The materials used in Example 1 were also used in Example 2. In order to improve the production efficiency of the composite sheet, the composite sheet was laminated in the manner of nickel metal sheet-polymer material-nickel metal sheet, and the laminated materials were pressed at 175°C for 10 minutes. The obtained composite sheet is punched into small discs with diameters of 2mm, 5mm and 8mm. This small disc can also be used as an electrical contact to produce silicone rubber keys.

Embodiment 3

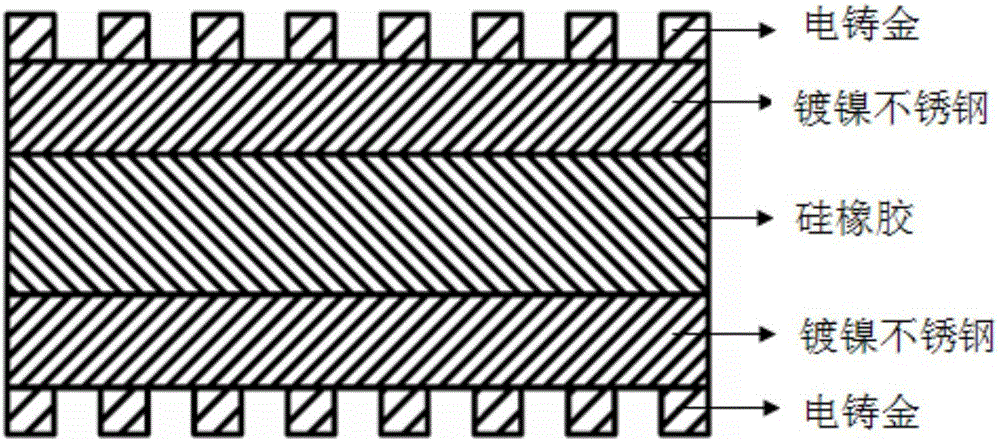

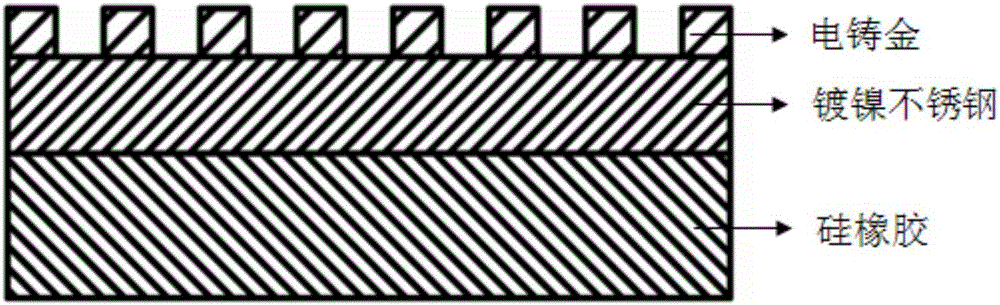

[0034] As in Example 1, but the metal sheet used is a 316 stainless steel sheet, the thickness of the stainless steel sheet is 0.1 mm, and the electroless plating method is used on the stainless steel sheet to first plate a layer of nickel coating with a thickness of 1 μm, and then electroplate the nickel coating. A cylindrical electroformed layer with an average thickness of 0.7 μm and a gold content of more than 99.9% is cast. The purpose of electroforming gold on the stainless steel sheet is to reduce the surface contact resistance of the electrical contacts and increase the electrical conductivity and service life of the electrical contacts. Using a flat vulcanizer, under the condition of 175°C×10 minutes, the electroformed gold stainless steel-polymer material-electroformed gold stainless steel is thermally vulcanized to make a composite sheet with a thickness of 1.0mm, and the composite sheet is punched Cut into small discs with a diameter of 5mm, the contact resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com