Die cutting die of battery pole piece and die cutting method thereof

A battery pole piece and die-cutting technology, applied in battery electrodes, electrode manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of low die-cutting efficiency, generated waste, and low utilization rate of substrates, and achieve high cutting efficiency, The effect of less waste and improved die-cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

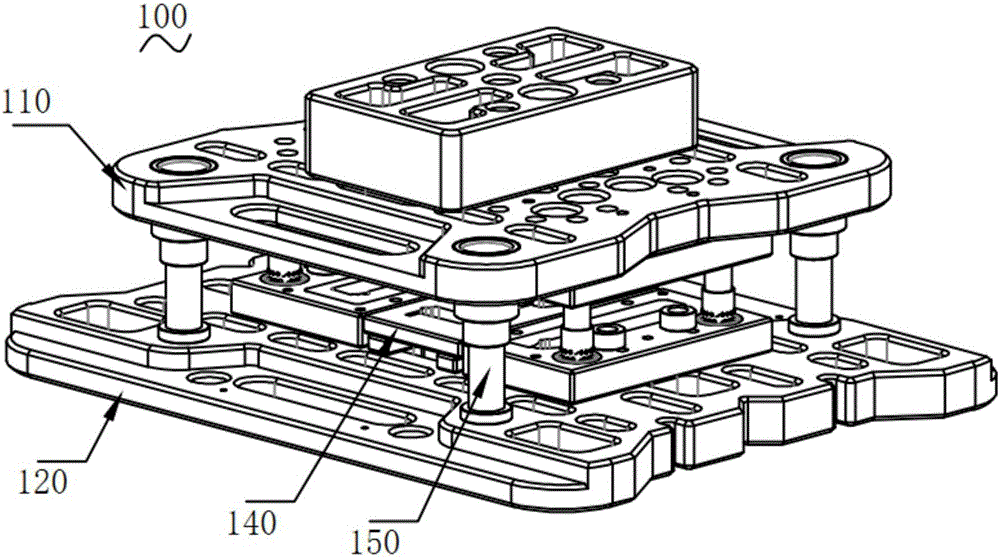

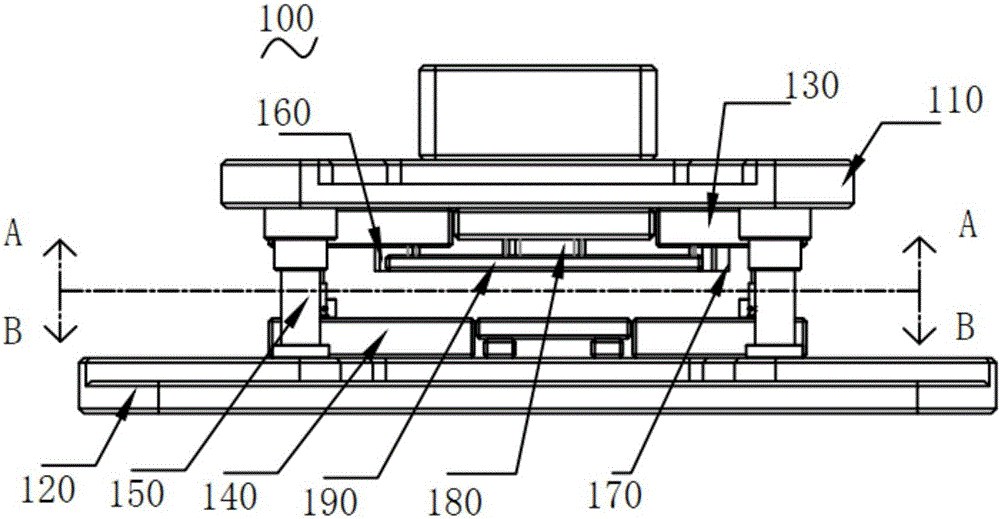

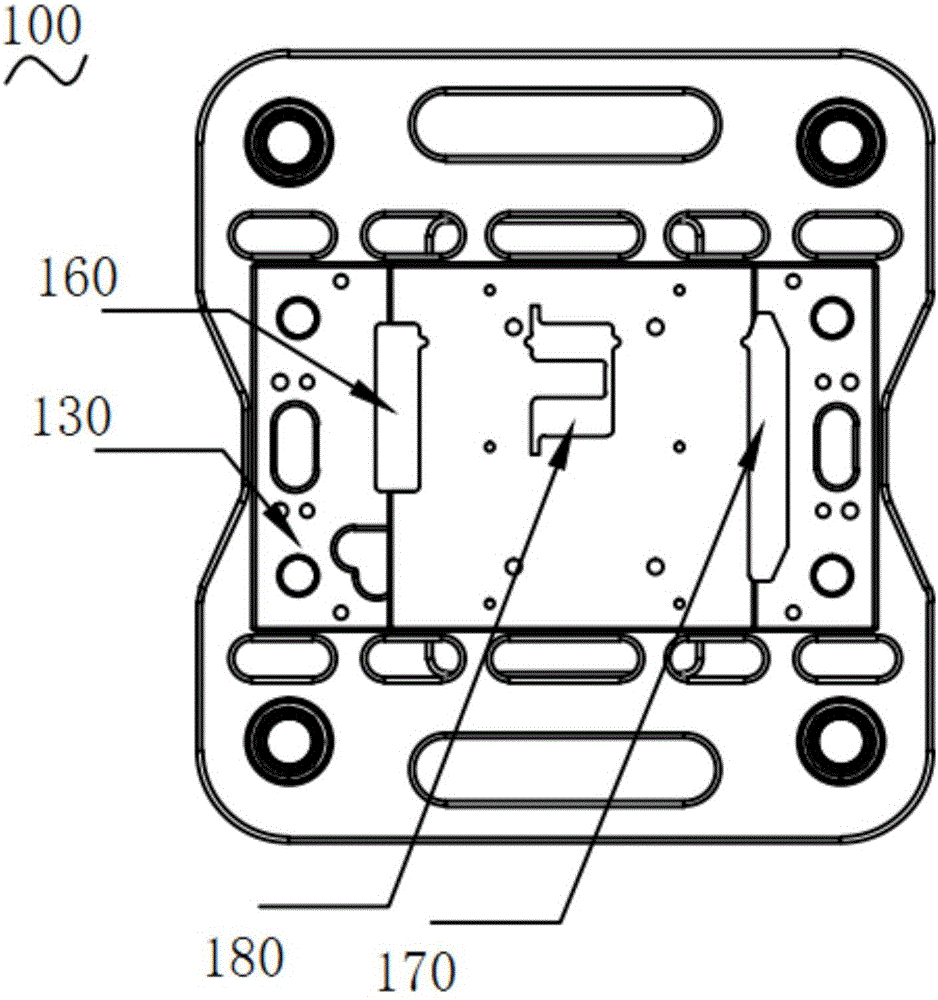

[0032] Such as Figure 1 ~ Figure 4 Shown are the perspective view, front view and cross-sectional view of different viewing angles of the battery pole piece die-cutting die.

[0033] The battery pole piece die-cutting die 100 comprises an upper mold fixing plate 110 and a lower mold fixing plate 120 arranged in parallel, an upper mold 130 arranged on the side of the upper mold fixing plate 110 close to the lower mold fixing plate 120, and an upper mold fixing plate 130 arranged on the lower mold fixing plate 120 is close to the lower mold plate 140 on the side of the upper mold fixed plate 110, and is installed on the lower mold fixed plate 120 and passes through the four guide columns 150 of the upper mold fixed plate 110. The upper mold fixed plate 110 and the upper mold plate 130 can be guided along the The column 150 moves back and forth toward the direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com