Nitrogen-doped-graphene-loaded Pd catalyst

A nitrogen-doped graphene and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low catalytic efficiency, uneven distribution of Pd, hindering catalytic efficiency, etc., and achieve excellent catalytic activity, reduced agglomeration, and high oxidation. The effect of reducing catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

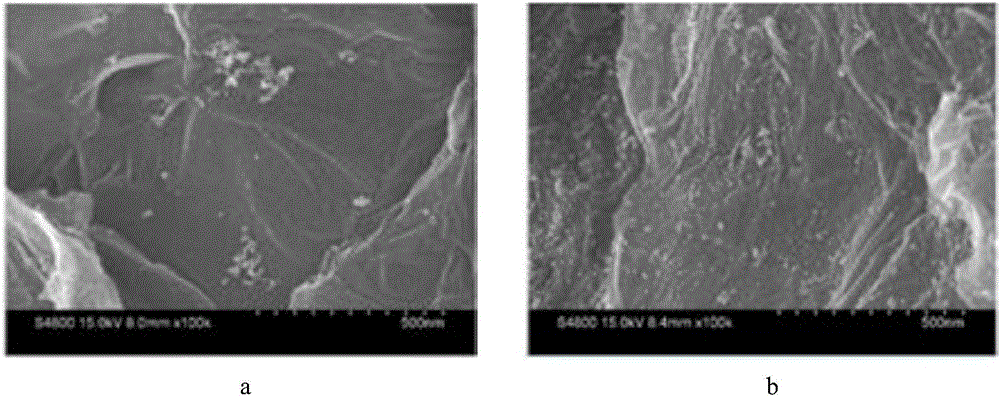

[0039] A nitrogen-doped graphene supported Pd catalyst, made from the following raw materials in parts by weight: 60 parts of nitrogen-doped graphene, PdCl 2 15 parts, 300 parts of potassium borohydride;

[0040] Wherein, nitrogen-doped graphene is made by following method:

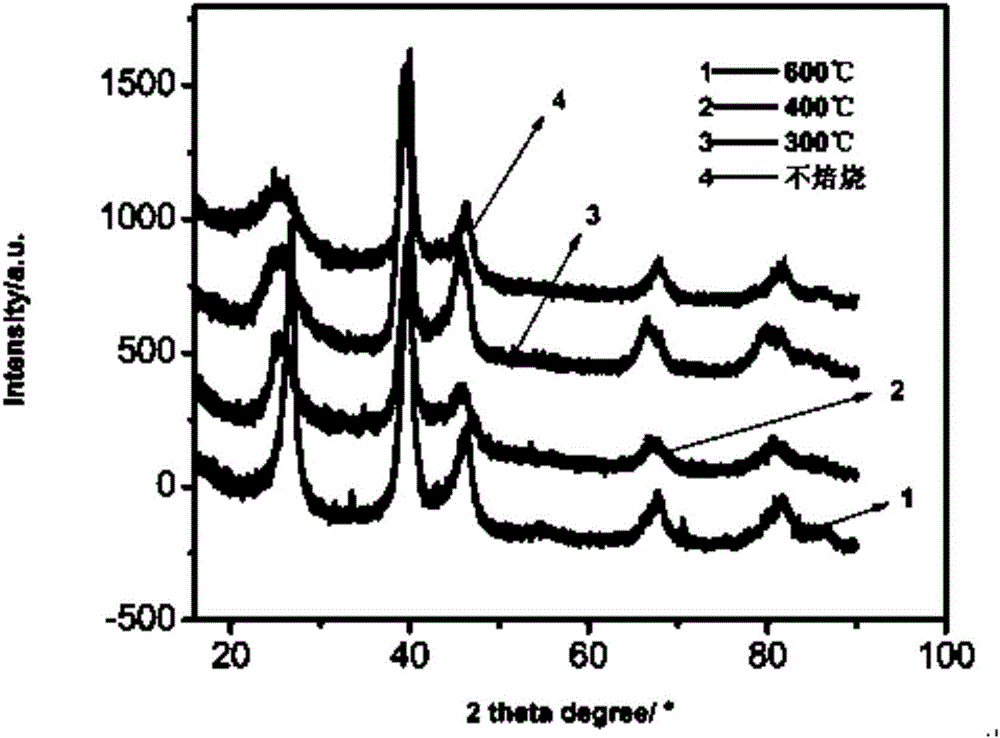

[0041] Adding 2700 parts by weight of ammonia to 30 parts by weight of graphene oxide, ultrasonic treatment for a long enough time to make it ink-like; putting the ink-like product and 2650 parts by weight of ammonia into hydrothermal reaction In the kettle, react at a temperature of 200° C. for 4 hours to obtain a nitrogen-doped graphene pre-product; react the nitrogen-doped graphene pre-product at 300° C. for 6 hours to obtain a nitrogen-doped graphene;

[0042] In addition, graphene oxide is produced by hummer method.

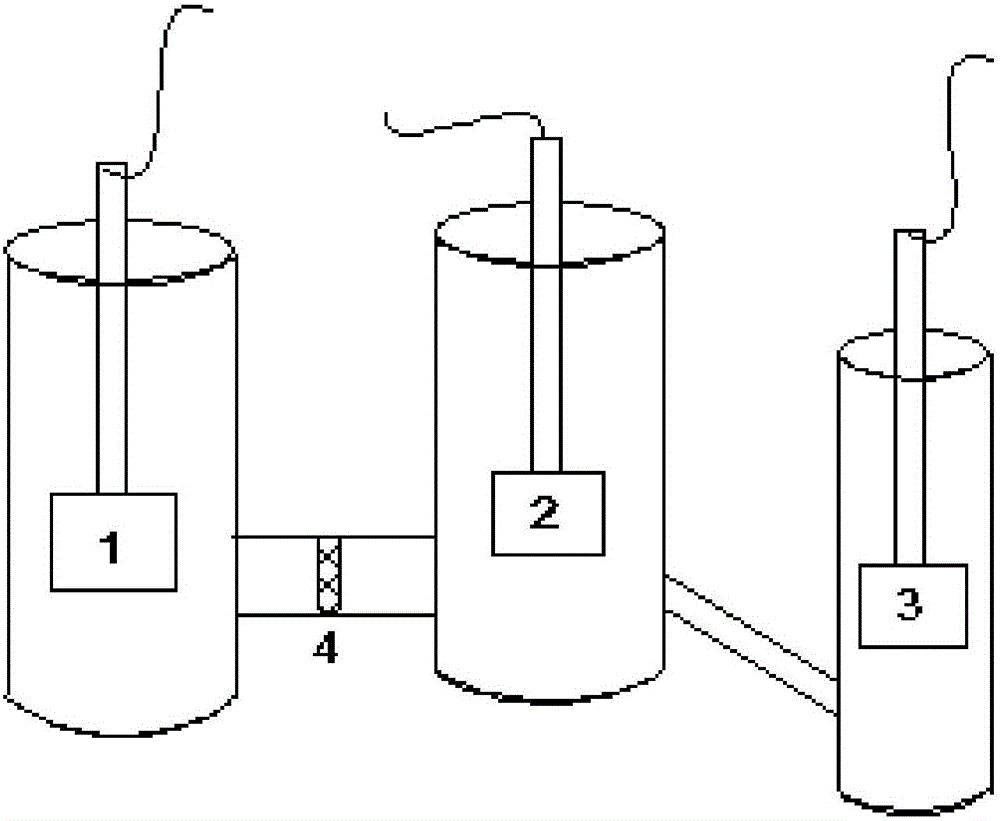

[0043] A preparation method of nitrogen-doped graphene supported Pd catalyst, comprising the following steps:

[0044] a) adding nitrogen-doped graphene into distilled water for ultr...

Embodiment 2

[0052] A nitrogen-doped graphene supported Pd catalyst, made from the following raw materials in parts by weight: 80 parts of nitrogen-doped graphene, PdCl 2 25 parts, 317 parts of potassium borohydride;

[0053] Wherein, nitrogen-doped graphene is made by following method:

[0054]Adding 2730 parts by weight of ammonia to 35 parts by weight of graphene oxide, ultrasonic treatment for a long enough time to make it ink-like; putting the ink-like product and 2730 parts by weight of ammonia into hydrothermal reaction In the kettle, react at a temperature of 210° C. for 5 hours to obtain a nitrogen-doped graphene pre-product; react the nitrogen-doped graphene pre-product at 400° C. for 6 hours to obtain a nitrogen-doped graphene;

[0055] In addition, graphene oxide is produced by hummer method.

[0056] A preparation method of nitrogen-doped graphene supported Pd catalyst, comprising the following steps:

[0057] a) adding nitrogen-doped graphene into distilled water for ultra...

Embodiment 3

[0065] A nitrogen-doped graphene supported Pd catalyst, made from the following raw materials in parts by weight: 90 parts of nitrogen-doped graphene, PdCl 2 30 parts, 320 parts of potassium borohydride;

[0066] Wherein, nitrogen-doped graphene is made by following method:

[0067] Adding 2800 parts by weight of ammonia to 35 parts by weight of graphene oxide, ultrasonic treatment for a long enough time to make it ink-like; putting the ink-like product and 2750 parts by weight of ammonia into hydrothermal reaction In the kettle, react at a temperature of 240° C. for 6 hours to obtain a nitrogen-doped graphene pre-product; react the nitrogen-doped graphene pre-product at 600° C. for 7 hours to obtain a nitrogen-doped graphene;

[0068] In addition, graphene oxide is produced by hummer method.

[0069] A preparation method of nitrogen-doped graphene supported Pd catalyst, comprising the following steps:

[0070] a) adding nitrogen-doped graphene into distilled water for ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com