Defect-rich metal bismuth and preparation method and application thereof

A defect-rich, metal-rich technology, applied in the field of defect-rich metals and their preparation, can solve problems such as low current density, danger, and selectivity decline, and achieve excellent stability, large electrochemically active surface area, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

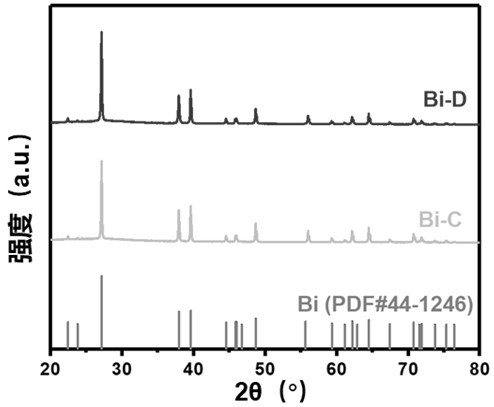

[0063] Example 1 of a preparation method of defect-rich metal bismuth (Bi-D)

[0064] (1) Add 1 mmol of bismuth neododecanoate and 300 mg of polyvinylpyrrolidone into 35 mL of ethylene glycol, and stir for 1 h at room temperature at a speed of 500 r / min until uniform to obtain solution A;

[0065] (2) Add 2 mmol of ascorbic acid to the solution A obtained in step (1), and stir for 1 h at room temperature at a rotation speed of 500 r / min until uniform to obtain solution B;

[0066] (3) Place the solution B obtained in step (2) in a 50 mL polytetrafluoroethylene-lined airtight reaction kettle, and in a constant temperature drying oven, heat up to 150°C at a heating rate of 6°C / min for solvothermal After reacting for 4 hours and cooling to room temperature naturally, the black precipitate was centrifuged and washed at a speed of 10,000 r / min (alternatively washed with deionized water and ethanol three times each), and dried in vacuum at 60°C and a vacuum of -0.04 MPa. After 12 h...

Embodiment 2

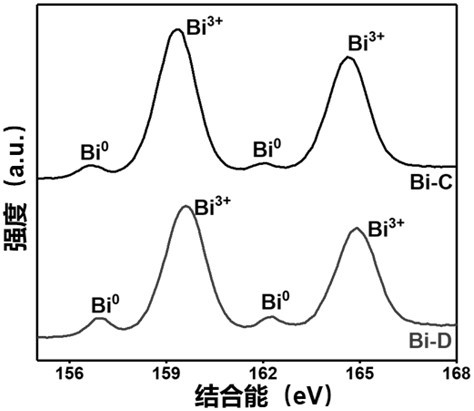

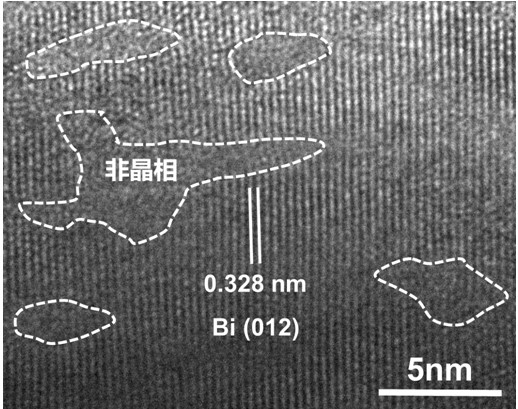

[0079]The defect-rich metal bismuth is flaky nano-particles with defect-containing amorphous phase distributed on the metal bismuth crystal phase; the crystal plane index of the main exposed crystal plane of the metal bismuth crystal phase is (012); the defects include vacancies, Dislocations and grain boundaries; the average thickness of the defect-rich metal bismuth is 130 nm; the defect-containing amorphous phase in the defect-rich metal bismuth accounts for 18% of the total area.

[0080] Example 3 of a defect-rich metal bismuth (Bi-D3)

[0081] The defect-rich metal bismuth is flaky nano-particles with defect-containing amorphous phase distributed on the metal bismuth crystal phase; the crystal plane index of the main exposed crystal plane of the metal bismuth crystal phase is (012); the defects include vacancies, Dislocations and defects; the average thickness of the defect-rich metal bismuth is 150 nm; the defect-containing amorphous phase in the defect-rich metal bismu...

Embodiment 3

[0091] (1) Add 2 mmol of bismuth neododecanoate and 300 mg of polyvinylpyrrolidone into 30 mL of ethylene glycol, and stir for 1 hour at room temperature at a speed of 600 r / min until uniform, to obtain solution A;

[0092] (2) Add 3 mmol of ascorbic acid to solution A obtained in step (1), and stir for 1 hour at room temperature with a rotation speed of 600 r / min until uniform to obtain solution B;

[0093] (3) Place the solution B obtained in step (2) in a 50 mL polytetrafluoroethylene-lined airtight reaction kettle, and in a constant temperature drying oven, heat up to 140°C at a heating rate of 4°C / min for solvothermal After reacting for 5 hours and cooling to room temperature naturally, the black precipitate was centrifuged and washed at a speed of 8000 r / min (alternatively washed with deionized water and ethanol 4 times each), and vacuum-dried at 50°C and vacuum degree of -0.03MPa for 14 hours , to get rich defect metal bismuth Bi-D3.

[0094] Application examples 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com