Nitrogen-doped graphene loaded Pd/Ni catalyst and preparation method thereof

A nitrogen-doped graphene and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as dispersibility, poor stability, easy agglomeration of composite catalysts, and catalytic activity to be improved. , to achieve high stability, high redox catalytic performance, and reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

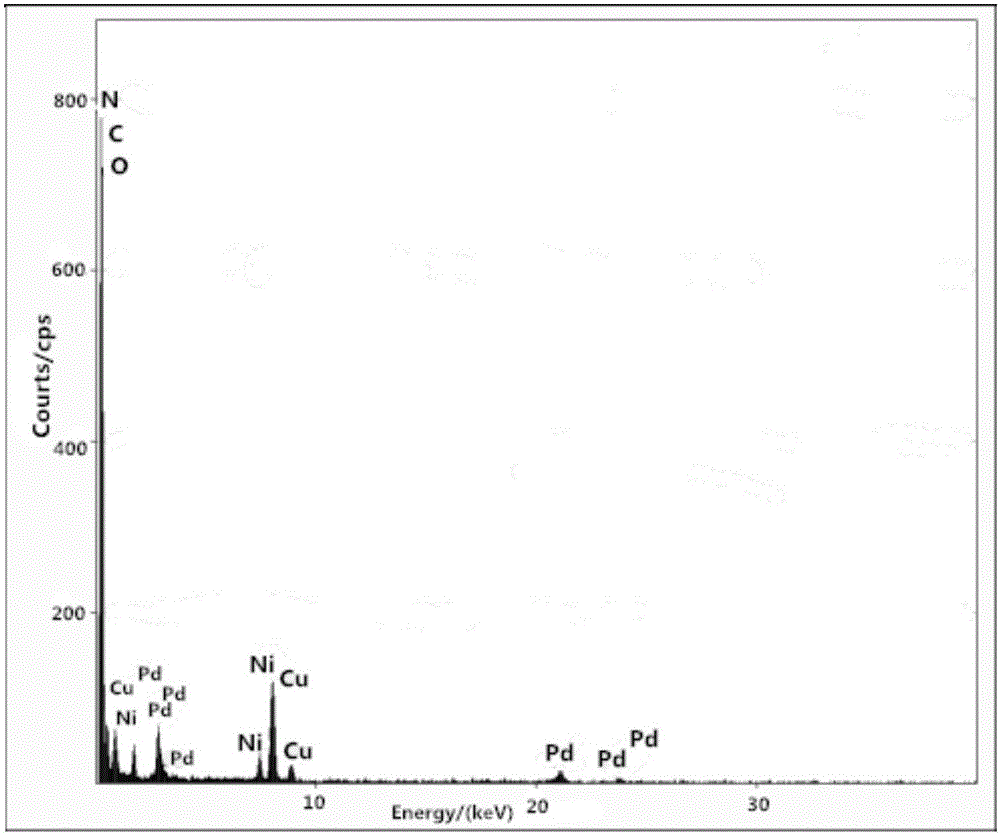

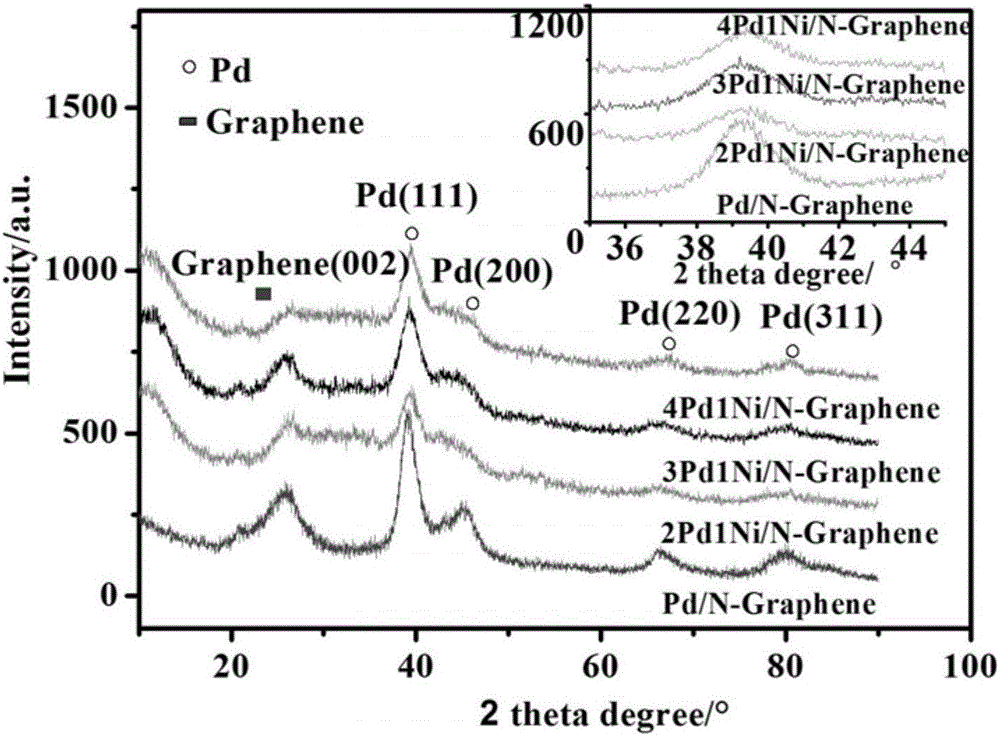

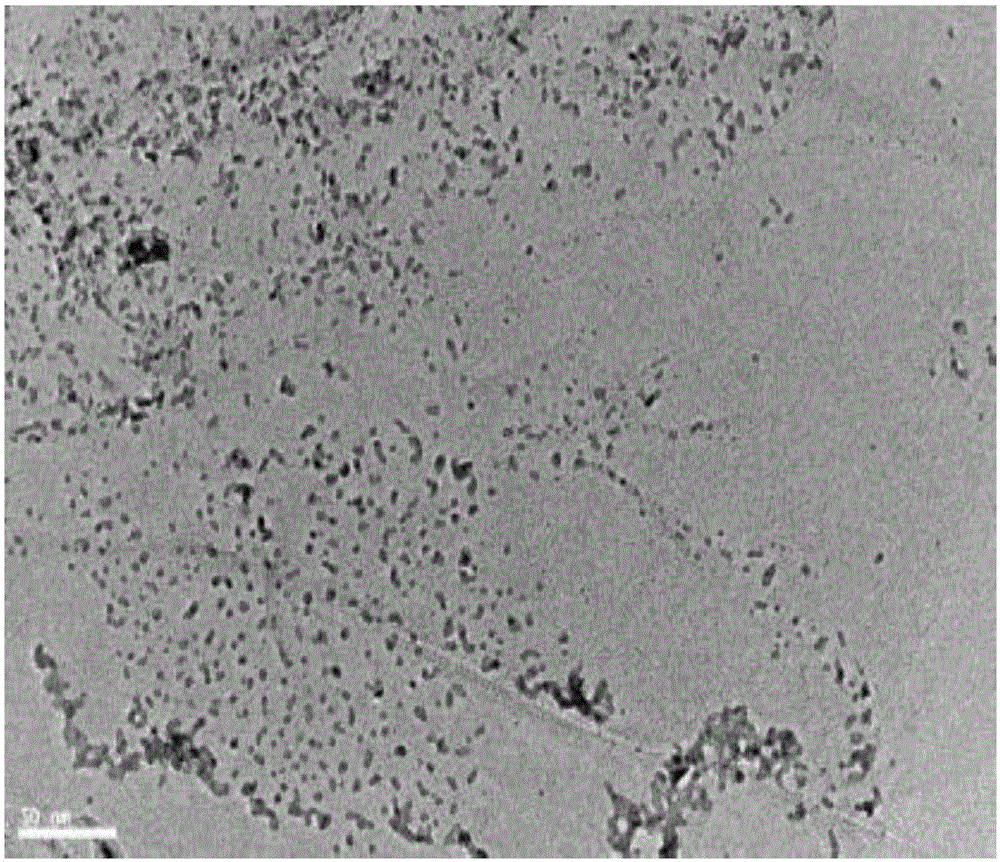

[0033] A nitrogen-doped graphene supported Pd / Ni catalyst, prepared from the following components by weight: NiSO 4 ·6H 2 1 part of O, 4 parts of nitrogen-doped graphene, 20 parts of potassium borohydride; also contains an appropriate amount of 0.05mol / L of PdCl 2 solution, so that the molar ratio of Ni to Pd is 1:2;

[0034] Wherein, nitrogen-doped graphene is made by following method:

[0035] Add graphene oxide into an appropriate amount of ammonia water and ultrasonically disperse for 10 minutes, then add the dispersed solution into a hydrothermal reaction kettle, and then react at a temperature of 200°C for 4 hours. Nitrogen-doped graphene was obtained by drying at ℃ for 10 hours; 150 ml of ammonia water was added to every 1 gram of graphene oxide.

[0036] A preparation method of nitrogen-doped graphene supported Pd / Ni catalyst, comprising the following steps:

[0037] a) adding nitrogen-doped graphene to distilled water for ultrasonic treatment to make it uniformly ...

Embodiment 2

[0044] A nitrogen-doped graphene supported Pd / Ni catalyst, prepared from the following components by weight: NiSO 4 ·6H 2 1 part of O, 5 parts of nitrogen-doped graphene, 23 parts of potassium borohydride; also contains an appropriate amount of 0.05mol / L of PdCl 2 solution, so that the molar ratio of Ni to Pd is 1:3;

[0045] Wherein, nitrogen-doped graphene is made by following method:

[0046]Add graphene oxide into an appropriate amount of ammonia water and ultrasonically disperse for 12 minutes, then add the dispersed solution into a hydrothermal reaction kettle, and then react at a temperature of 210°C for 5 hours. Nitrogen-doped graphene was obtained by drying at ℃ for 12 hours; wherein 150 ml of ammonia water was added to 1 gram of graphene oxide.

[0047] A preparation method of nitrogen-doped graphene supported Pd / Ni catalyst, comprising the following steps:

[0048] a) adding nitrogen-doped graphene to distilled water for ultrasonic treatment to make it uniformly...

Embodiment 3

[0055] A nitrogen-doped graphene supported Pd / Ni catalyst, prepared from the following components by weight: NiSO 4 ·6H 2 1 part of O, 6 parts of nitrogen-doped graphene, 25 parts of potassium borohydride; also contains an appropriate amount of 0.05mol / L of PdCl 2 solution, so that the molar ratio of Ni to Pd is 1:4;

[0056] Wherein, nitrogen-doped graphene is made by following method:

[0057] Add graphene oxide into an appropriate amount of ammonia water and ultrasonically disperse for 15 minutes, then add the dispersed solution into a hydrothermal reaction kettle, and then react at a temperature of 250°C for 6 hours. Nitrogen-doped graphene was obtained by drying at ℃ for 14 hours; wherein 150 ml of ammonia water was added to 1 gram of graphene oxide.

[0058] A preparation method of nitrogen-doped graphene supported Pd / Ni catalyst, comprising the following steps:

[0059] a) adding nitrogen-doped graphene to distilled water for ultrasonic treatment to make it uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com