A kind of solid contact polymer film lead ion selective electrode and its application

A polymer film, lead ion technology, applied in the direction of material analysis, measurement device, instrument, etc. by electromagnetic means, can solve the problems of limiting the application of conductive polymers, and achieve increased electrochemical active surface area, good reproducibility, and response. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific preparation steps of the solid contact polymer membrane lead ion selective electrode are as follows:

[0029] a. Preparation of sensitive film: a mixture of PVC particles, o-nitrophenyl octyl ether, lead ionophore and sodium tetrakis(3,5-bis(trifluoromethyl)phenyl)borate total 250mg, of which 32.85wt% PVC particles, 65.71wt% o-nitrophenyl octyl ether, 1.0wt% lead ionophore and 0.44wt% sodium tetrakis(3,5-bis(trifluoromethyl)phenyl)borate, transferred to 2.0ml tetrahydrofuran solution , Ultrasound and stir for 2h to make it evenly dispersed.

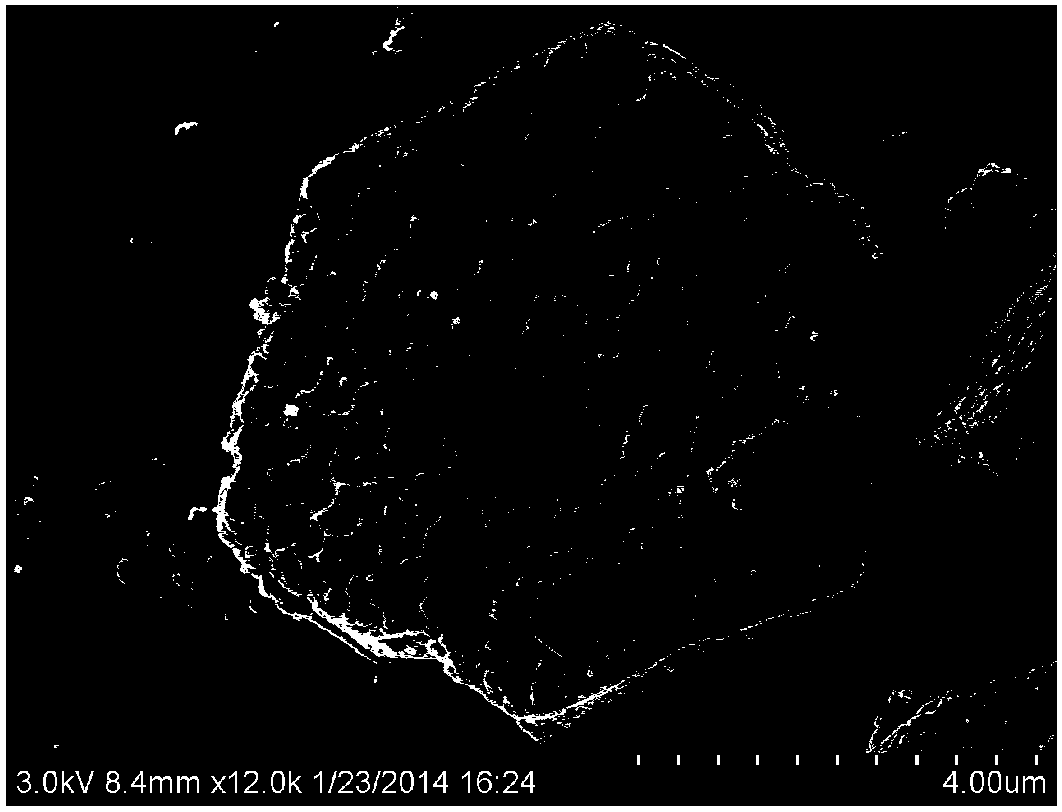

[0030] b. Hexagonal disc shape double die hole C 60 Preparation: Weigh 7mg of C 60 Powder, dissolve it in 10ml mixed solution of carbon tetrachloride:benzene=9:1 (v / v), filter it under 100W power for 45min, get C 60 The saturated solution should be placed in a refrigerator at 5°C for later use. Take 1ml of C 60 Put the saturated solution in a 15ml glass bottle, and then slowly add 5ml of isopropanol (maintaining the rate o...

Embodiment 2

[0035] The electrode obtained above should be in 10 -3 M lead nitrate activated for 30h, and then 10 -9 M is activated in lead nitrate for two days.

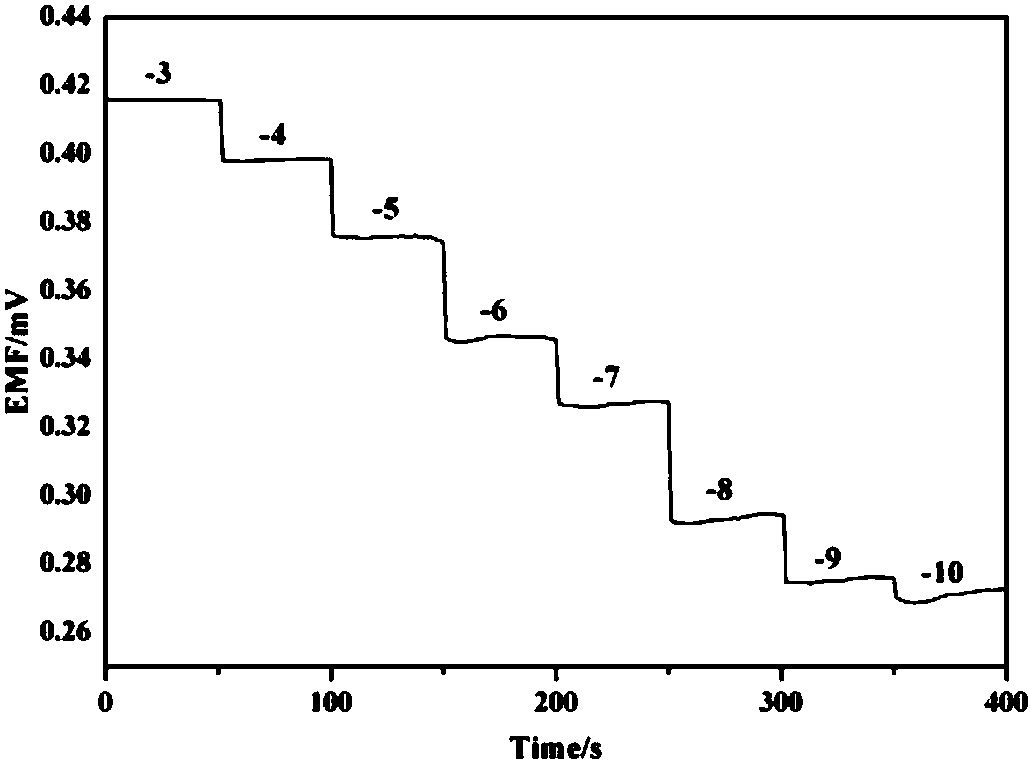

[0036] Insert the activated electrodes into the lead nitrate solution containing a series of different concentrations (the concentration of lead nitrate solution is 10 -3 , 10 -4 , 10 -5 , 10 -6 ,10 -7 , 10 -8 , 10 -9 , 10 -10 mol / L) to generate a potential response signal (see figure 2 ).

[0037] by figure 2 It can be seen that with double die hole C 60 The solid contact polymer membrane lead ion selective electrode with solid contact layer has a very sensitive potential response and can finally detect 10 -10 mol / L lead ion concentration, and the potential is 10 -4 -10 -7 Nernst response is present in the mol / L range.

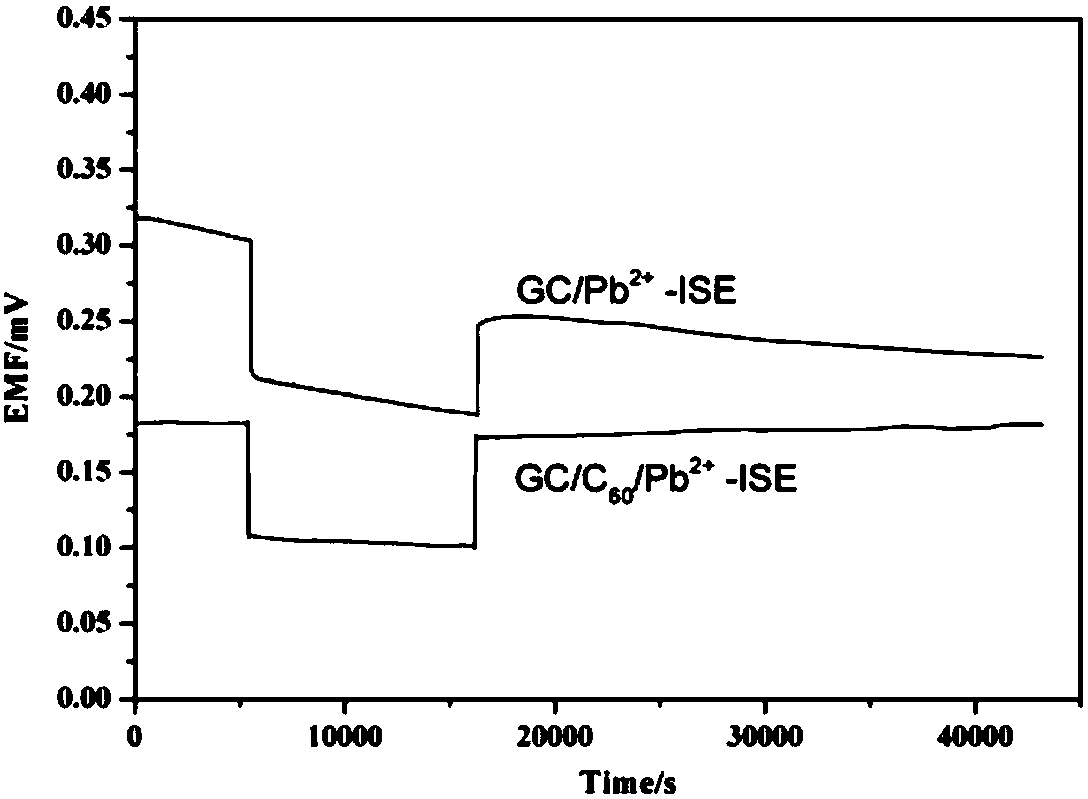

[0038] Then insert the activated electrodes into 10 -3 1.5h in mol / L lead nitrate solution, 10 -1 mol / L calcium nitrate solution for 3h, 10 -3 mol / L lead nitrate solution for 12h for water layer test (see image 3 )...

Embodiment 3

[0042] a. Electrophoresis deposition double mold hole C 60 :Combine the synthesized double-die hole C 60 First dissolve in toluene, and mix the dissolved mixture with acetonitrile again at a volume ratio of 1:3 to form a suspension of 0.05 mg / ml. Under the condition of 5V voltage, accompanied by 800r p m Magnetic stirring deposition for 12 minutes, it can be deposited on the surface of the glassy carbon electrode to obtain a uniform and dense C with a thickness of 0.15mm 60 Sedimentary layer.

[0043] b. The rest of the implementation steps refer to step d of Example 1 and Example 2, and a solid contact polymer membrane lead ion selective electrode can be obtained. -3 -10 -10 The potential change response of M lead nitrate solution and the electrode at 10 -3 Water layer test in M lead nitrate solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com