Semi-cycle three-phase T-shaped multi-level converter capacitor mid-point voltage balance control strategy

A voltage balance and converter technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc. tube overvoltage damage and other problems, to reduce the midpoint voltage fluctuation amplitude, improve the quality of output power, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

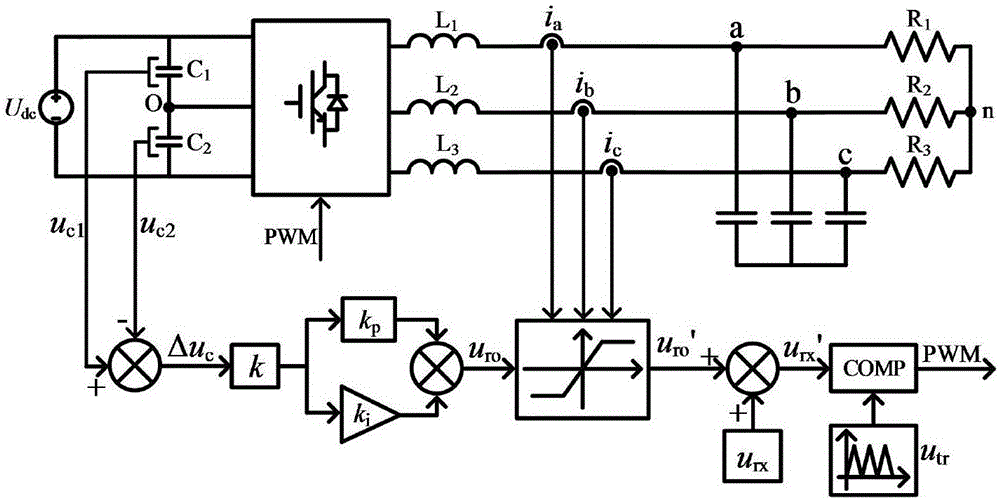

[0022] The sinusoidal pulse width modulation strategy of the three-phase T-type three-level inverter of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0023] refer to figure 1 and figure 2 , the three-phase T-type three-level inverter sinusoidal pulse width modulation strategy of the present invention includes the following:

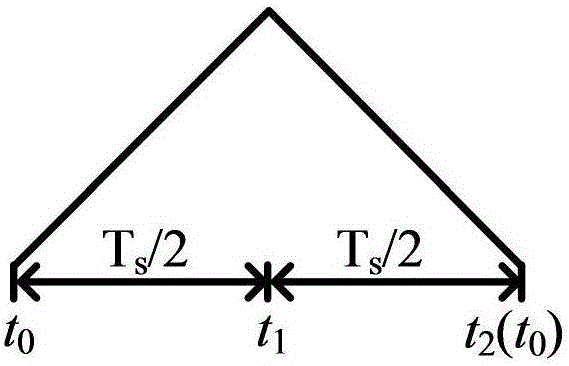

[0024] 1) When the converter adopts dual-carrier in-phase SPWM control strategy, the three-phase modulated wave u in one carrier period ra , u rb and u rc with two carriers u c1 and u c2 Comparing to obtain a total of six switch tube PWM drive signals T in each phase A1 , T A2 , T B1 , T B2 , T C1 and T C2 , to control the opening and closing of the switching tubes of each phase. Let the start time of a switching cycle be t 0 , the middle moment is t 1 , the end time is t 2 ;

[0025] 2) At each switching cycle t 0 Collect the output current of the AC side of the converter at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com