Horizontal film evaporator

A thin film evaporator, horizontal technology, applied in the field of concentration equipment, can solve the problems of few application scenarios, product pollution, high maintenance cost, etc., and achieve the effect of simple overall structure principle, short material residence time, and safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

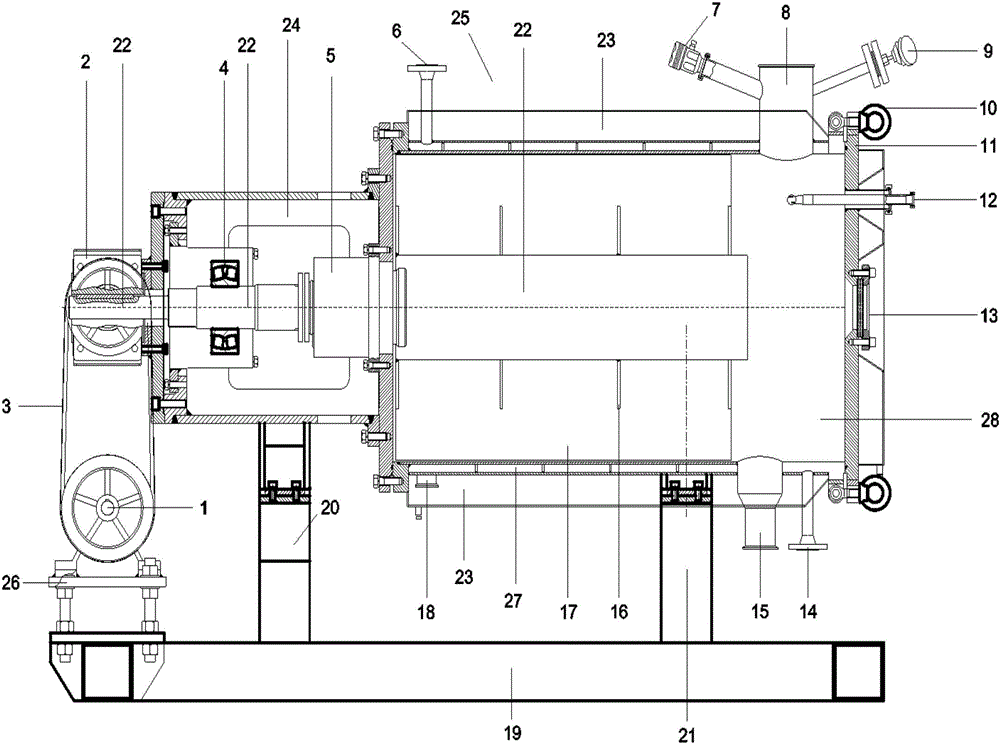

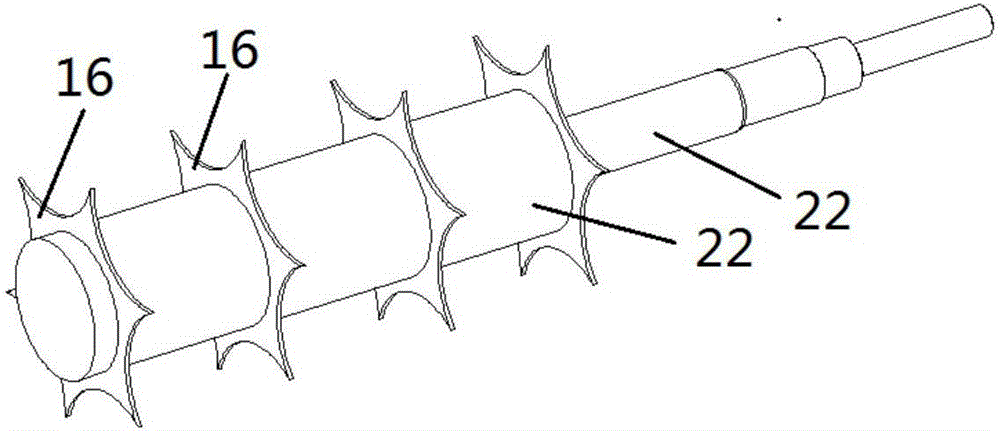

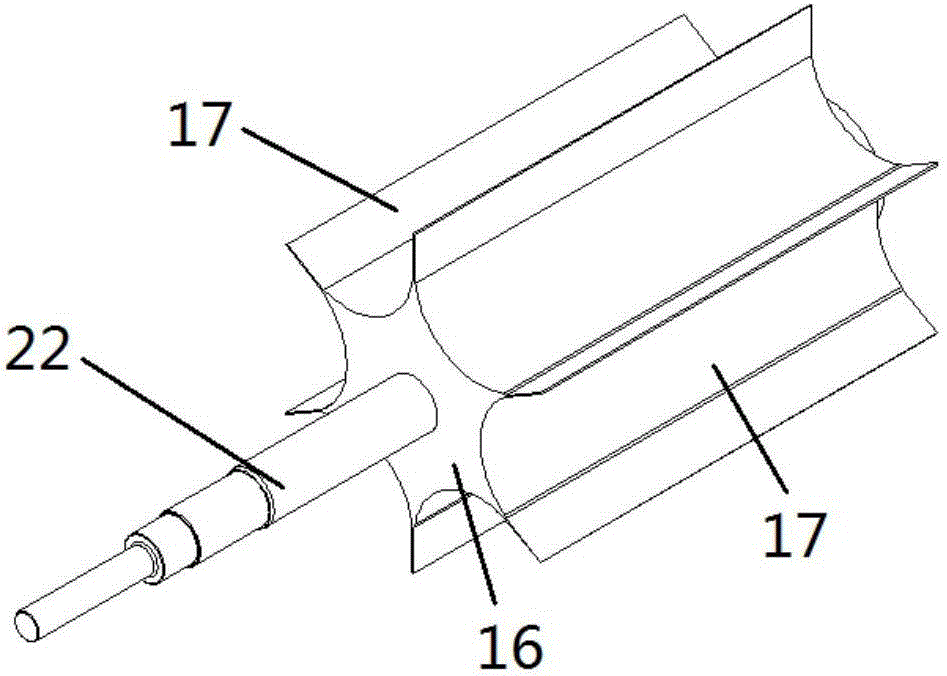

[0016] The main structure of the horizontal thin film evaporator involved in this embodiment includes a motor 1, a reducer 2, a belt 3, a bearing 4, a mechanical seal 5, a medium inlet 6, a pressure transmitter 7, a vacuum port 8, and a temperature transmitter 9. Joint bolt 10, movable head 11, cleaning spray ball 12, sight glass 13, medium outlet 14, discharge port 15, support plate 16, arc scraper 17, feed port 18, base 19, the first A leg 20, a second leg 21, a rotating shaft 22, an insulation layer 23, a reducer support 24, a heating tank body 25, a motor fixing seat 26, a heating jacket 27 and an evaporation chamber 28; the motor 1 passes through the motor fixing seat 26 It is detachably fixed at one end of the base 19, and the base 19 is a welded steel frame structure, which is fixed horizontally on the ground plane; the first leg 20 and the second leg 21 are respectively fixed on the base 19, and the first leg 20 and the second leg 21 are both symmetrical steel frame st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com