Hydrogen evolution catalyst and preparation method thereof

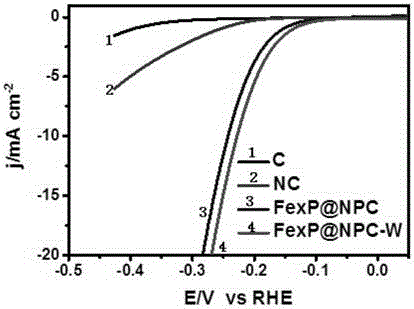

A catalyst and hydrogen evolution technology, applied in the field of catalysis, can solve the problems of high price and limited large-scale application, and achieve the effects of long activity and life, simple preparation process and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

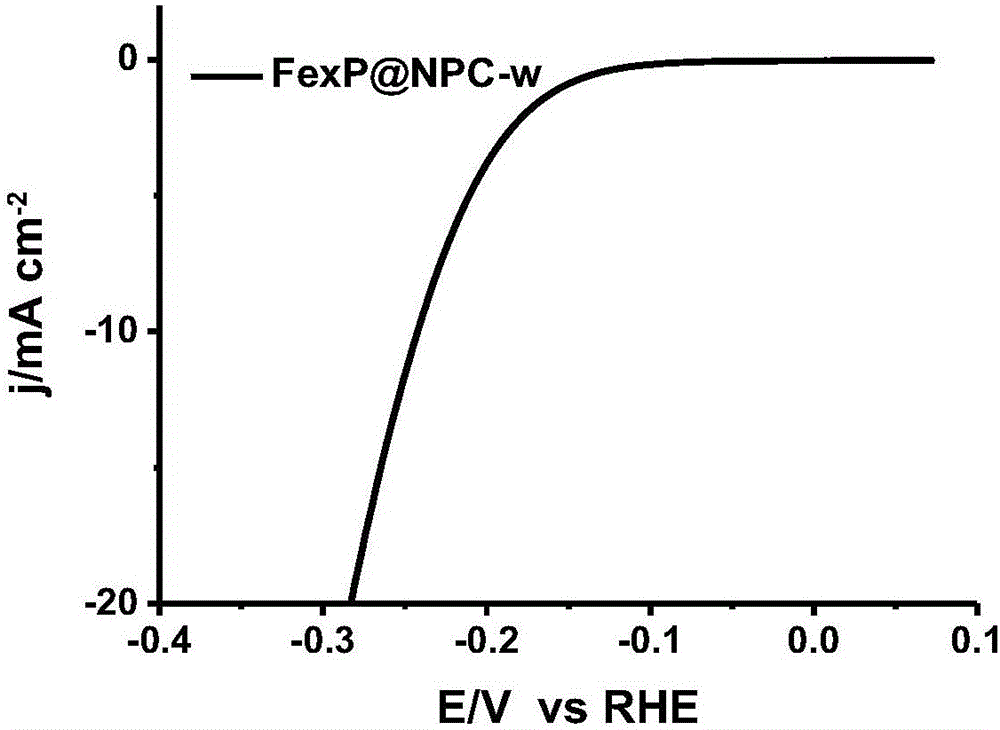

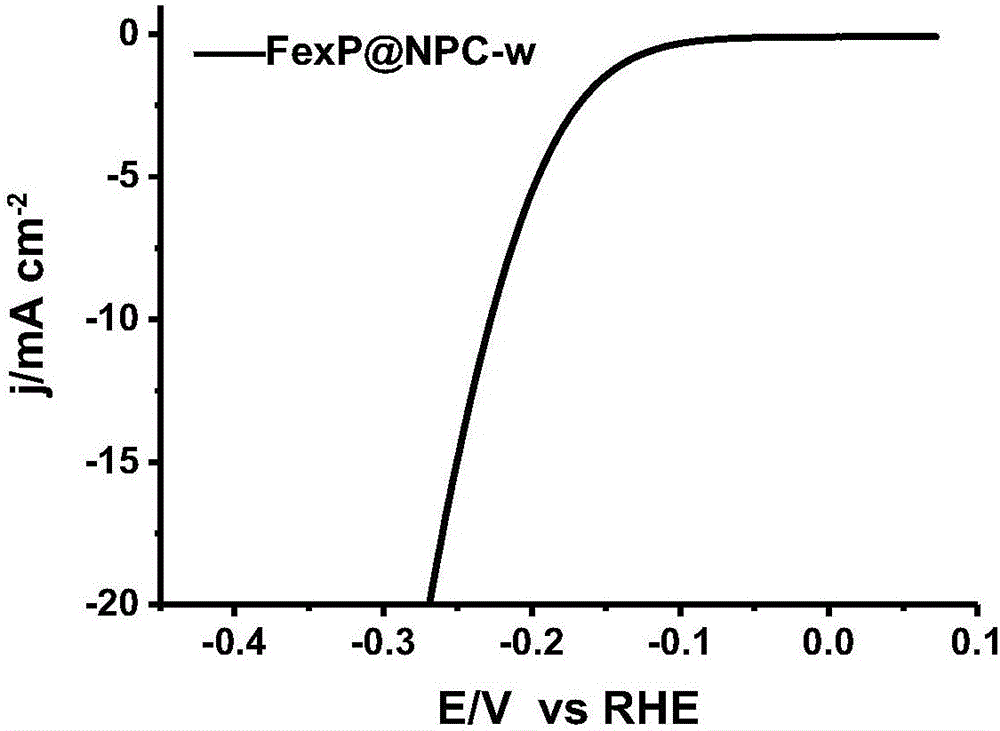

Embodiment 1

[0033] Take by weighing 6.75g (24.97mmol) ferric chloride crystals (FeCl3 6H 2 O) Add 75mL of dimethylformamide (DMF), weigh 2.25g (12.42mmol) of 2-aminoterephthalic acid into 75mL of dimethylformamide (DMF).

[0034] The two solutions were mixed, then transferred to a 200mL reactor, and the reactor was heated to 110°C for 24 hours of reaction.

[0035] The resulting product was washed with suction several times with DMF and methanol. Dry in an oven at 60°C for 12 hours. The precursor of C, N, Fe (NH2-MIL-101(Fe)) was obtained.

[0036] Weigh 1 g of the synthesized C, N, Fe precursors and 1 g of glyphosate into 150 ml of DMF solution, and stir at 55° C. for 8 h.

[0037] The product was then washed with suction several times with DMF and ethanol. Dry in an oven at 60°C for 12 hours. Dry to obtain a precursor containing C, Fe, P, N (NH2-MIL-101(Fe)-P).

[0038] The synthesized precursors containing C, Fe, P, and N were moved into a high-temperature furnace for burning, an...

Embodiment 2

[0041] Weigh 5.04g (12.49mmol) of ferric sulfate and add it in 40mL dimethylformamide (DMF), weigh 1.12g (6.21mmol) of 2-aminoterephthalic acid and add it in 40mL dimethylformamide (DMF )middle.

[0042] The two solutions were mixed, and then transferred to a 100mL reactor, and the reactor was heated to 120°C for 24 hours of reaction.

[0043] The resulting product was washed with suction several times with DMF and methanol. Dry in an oven at 60°C for 8 hours. A precursor (NH2-MIL-101(Fe)) for obtaining C, N, Fe was obtained.

[0044] Weigh 0.5g of the synthesized Fe, N-containing material and 1g of glyphosate into 80ml of DMF solution, and stir at 60°C for 8h.

[0045]The product was then washed with suction several times with DMF and ethanol. Dry in an oven at 60°C for 8 hours. Dry to obtain a precursor containing C, Fe, P, N (NH2-MIL-101(Fe)-P).

[0046] The synthesized materials containing Fe, P, and N were moved into a high-temperature furnace for firing, and the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com