Microfluidic module for large-scale preparation of liquid drops

A microfluidic, droplet technology, applied in the fields of measuring tubes/pipettes, chemical instruments and methods, laboratory containers, etc. problem, to achieve the effect of high sphericity, good monodispersity, and guaranteed distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

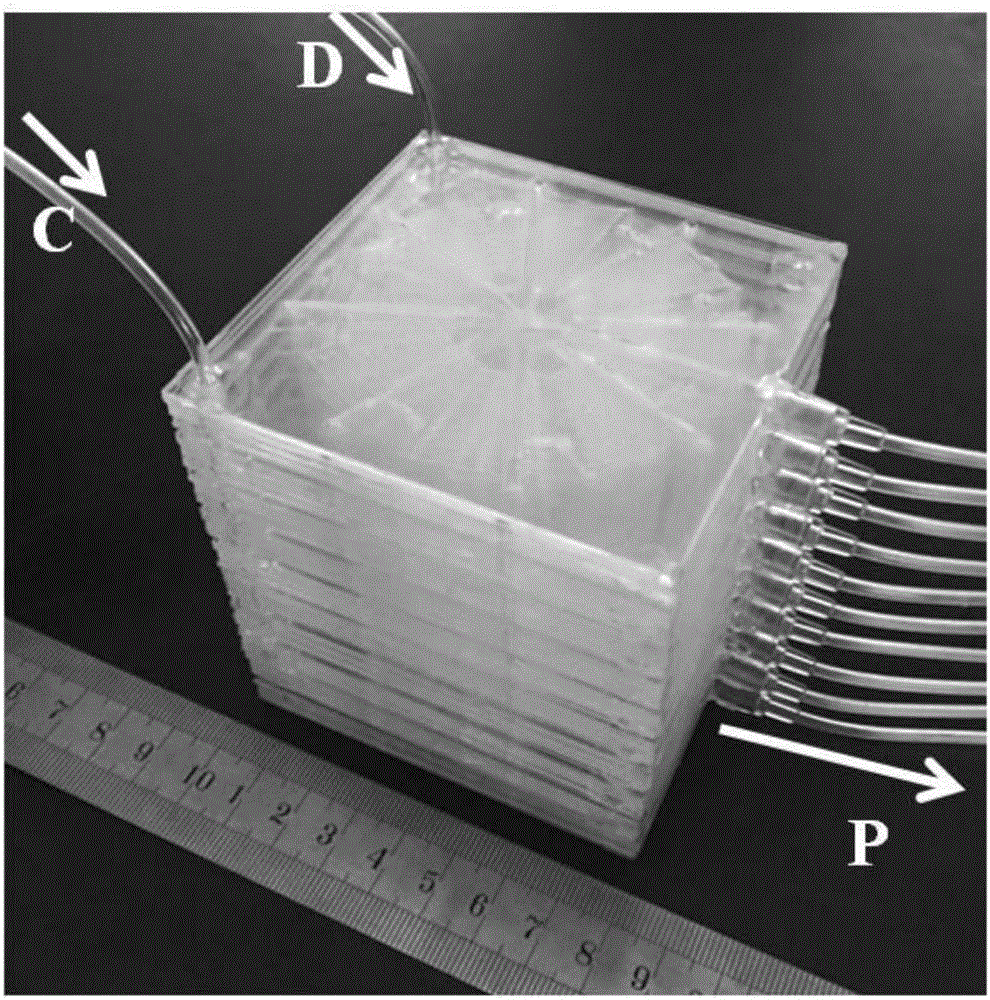

[0038] The cheap polymethyl methacrylate PMMA was selected as the substrate material, and a laser engraving platform was used to establish a microfluidic control to prepare a droplet chip. Multiple microfluidic modules were prepared through parallel connection and stacking, and multiple modules were integrated and operated.

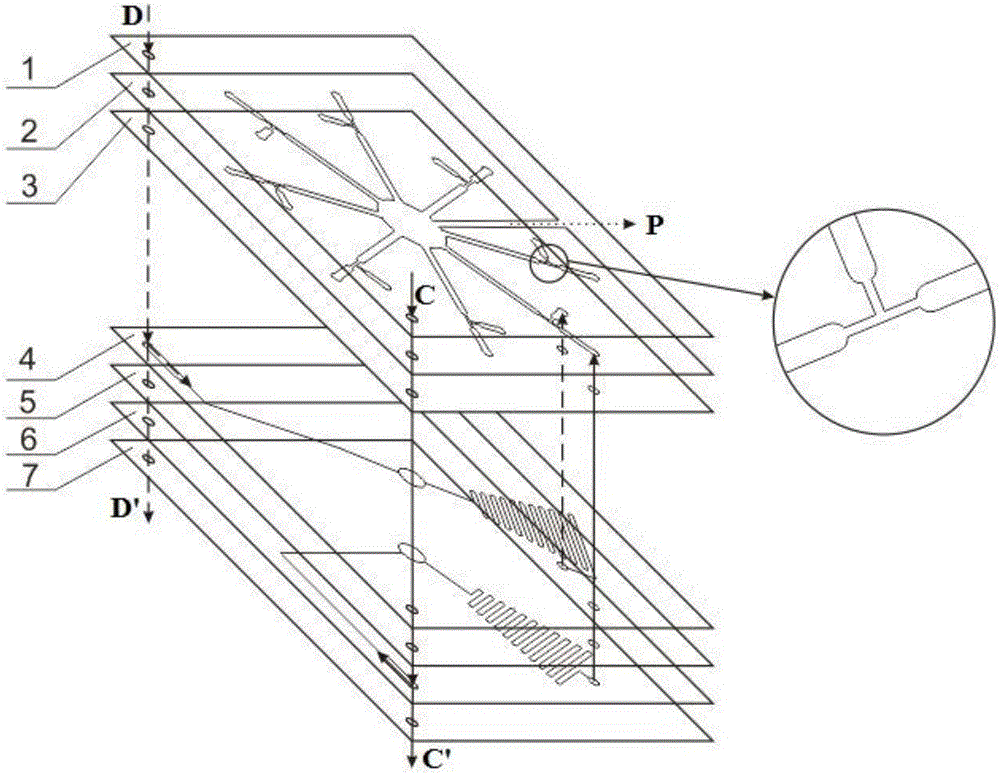

[0039] Such as figure 1 As shown, the chipset consists of seven layers including upper and lower cover plates 1 and 7, droplet preparation layer 2, fluid distribution layers 4 and 6, and spacer layers 3 and 5; the thickness of the upper and lower cover plates is 1mm, and the thickness of the droplet preparation layer The thickness of the fluid distribution layer is 1.5mm, the thickness of the spacer layer is 0.5mm, and the size of each layer of the chip is 80mm×80mm;

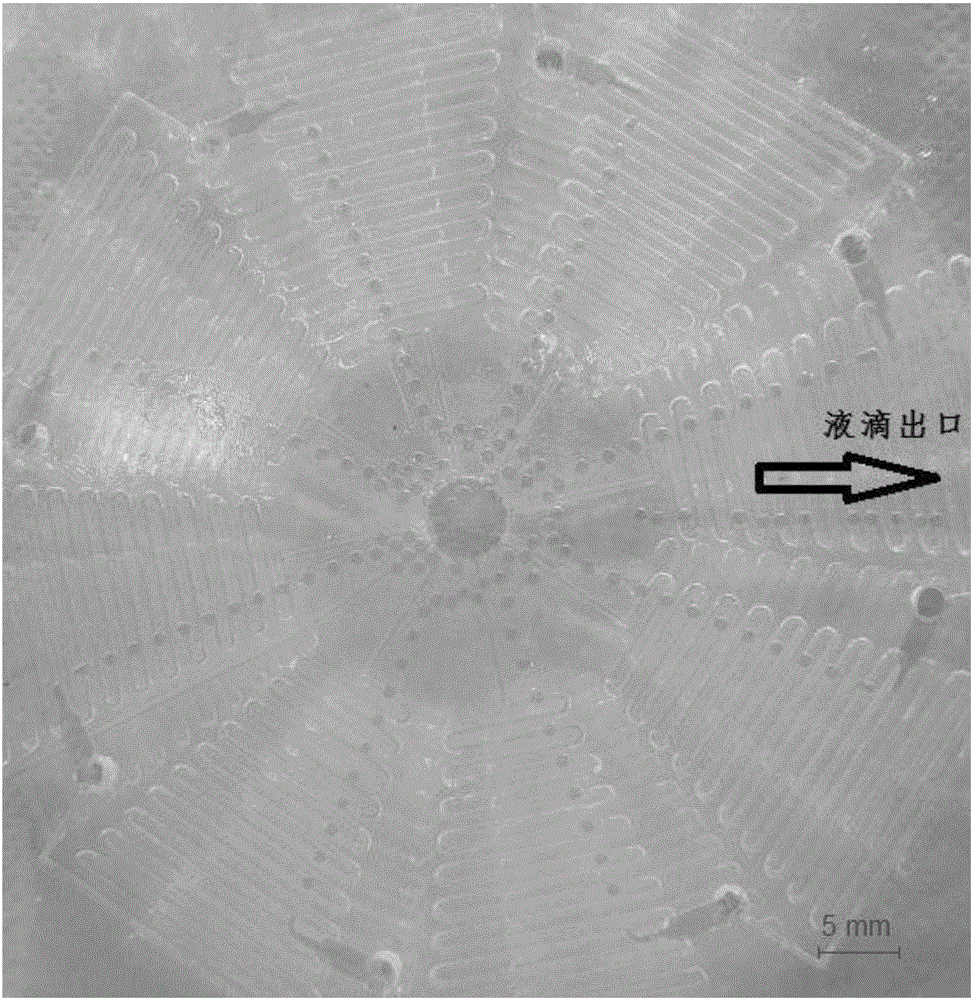

[0040] Eight T-shaped droplet preparation units are connected in parallel in the circumferential direction of the droplet preparation layer, and the size of the intersection is 500 μm×500 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com