Welding method of non-preheating before welding and non-heat-treatment after welding of V-N microalloying Q550D medium plate

A technology without heat treatment after welding and without preheating before welding, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problem of unstable weldability of thick plates such as heat treatment, and promote the nucleation of acicular ferrite , Improve the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

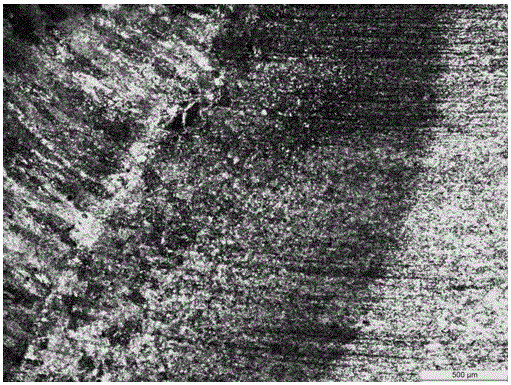

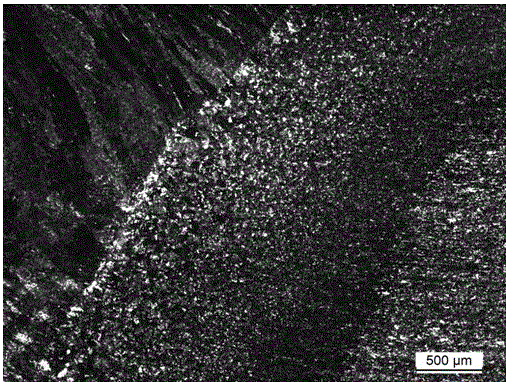

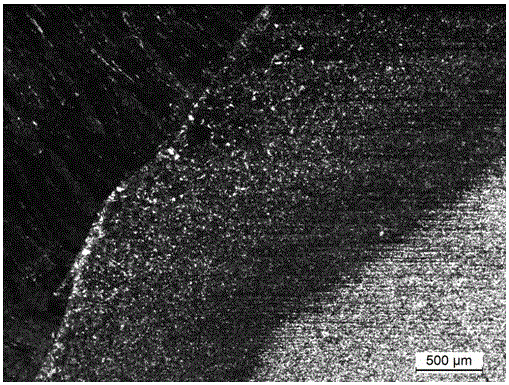

Image

Examples

Embodiment 1

[0039] The welding method of the V-N microalloyed Q550D medium and thick plate of this embodiment without preheating before welding and without heat treatment after welding is carried out according to the following steps:

[0040] (1) Make a double V-shaped groove at the joint of the V-N microalloyed Q550D medium and thick plate to be welded, the groove angle is 30°, the blunt edge is 1mm, and the pair gap is 1.5mm; the thickness of the plate to be welded is 20mm, and the yield strength It is 651MPa, the tensile strength is 733MPa, and the elongation is 18.0%;

[0041] (2) Use 400CCR / R sandpaper to grind the groove and the surface of the plate to be welded on both sides to remove scale and rust;

[0042] (3) Fix the medium and thick plates to be welded with bolts, and then carry out Ar+CO 2 Mixed gas shielded tack welding, the welding voltage of tack welding is 20V, the welding current is 180A, the welding speed is 360mm / min, and the input energy is 6.0KJ / cm;

[0043] (4) Af...

Embodiment 2

[0047] The welding method of the V-N microalloyed Q550D medium and thick plate of this embodiment without preheating before welding and without heat treatment after welding is carried out according to the following steps:

[0048] (1) Make a double V-shaped groove at the joint of the V-N microalloyed Q550D medium and thick plate to be welded, the groove angle is 35°, the blunt edge is 2mm, and the pair gap is 2mm; the thickness of the plate to be welded is 20mm, and the yield strength is 651MPa, tensile strength 733MPa, elongation 18.0%;

[0049] (2) Use 400CCR / R sandpaper to grind the groove and the surface of the plate to be welded on both sides to remove scale and rust;

[0050] (3) Fix the medium and thick plates to be welded with bolts, and then carry out Ar+CO 2 Mixed gas shielded tack welding, the welding voltage of tack welding is 23.5V, the welding current is 196A, the welding speed is 390mm / min, and the input energy is 7.1KJ / cm;

[0051] (4) After the tack welding ...

Embodiment 3

[0055] The welding method of the V-N microalloyed Q550D medium and thick plate of this embodiment without preheating before welding and without heat treatment after welding is carried out according to the following steps:

[0056] (1) Make a double V-shaped groove at the joint of the V-N microalloyed Q550D medium and thick plate to be welded, the groove angle is 40°, the blunt edge is 2mm, and the pairing gap is 2mm; the thickness of the plate to be welded is 30mm, and the yield strength is 625MPa, tensile strength 724MPa, elongation 20.0%;

[0057] (2) Use 400CCR / R sandpaper to grind the groove and the surface of the plate to be welded on both sides to remove scale and rust;

[0058] (3) Fix the medium and thick plates to be welded with bolts, and then carry out Ar+CO 2 Mixed gas shielded tack welding, the welding voltage of tack welding is 24V, the welding current is 200A, the welding speed is 330mm / min, and the heat input=8.7KJ / cm;

[0059] (4) After the tack welding is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com