Composite material toughed by flexible material for cases as well as preparation and application thereof

A technology of flexible materials and composite materials, which is applied in the field of composite materials toughened by flexible materials for luggage and its preparation and application, can solve the problems of non-recyclability, small specific gravity, and decline, and achieve prolonging service life, improving impact resistance, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

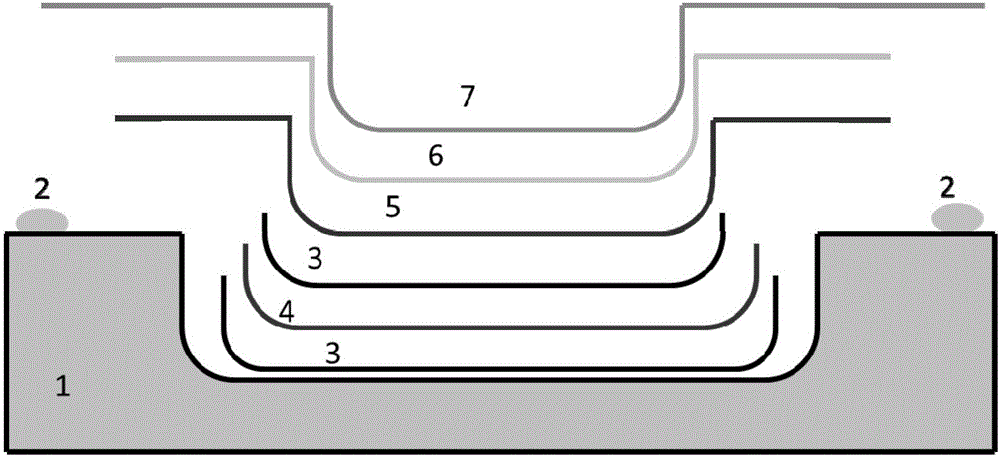

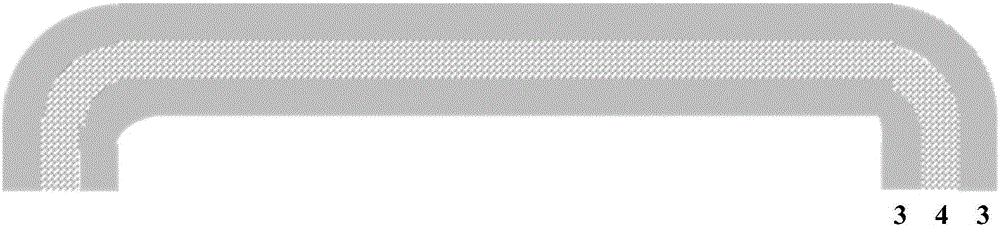

[0025] Such as figure 1 As shown, clean the bag mold 1 (clean the mold with acetone), then paste the sealing tape 2 according to the shape and size of the bag, apply the release agent, and lay the cut carbon fiber prepreg 3 on the surface coated with the release agent. On the mold 1, after laying the specified number of layers (1 layer of plain carbon fiber prepreg with a thickness of 0.2mm), lay the toughening material 4 (toughening material with a thickness of 0.2mm), and then continue laying the carbon fiber prepreg material, the laid carbon fiber prepreg is 1 layer, after the completion, place the isolation film 5 (the isolation film can cover the prepreg in the box) and the air felt 6, seal the system with the vacuum bag 7, and then press the The curing is completed in the tank according to the curing system (curing at 0.6MPa pressure and 150°C for 30 minutes). After cooling down, the mold can be demoulded to obtain a well-formed toughened carbon fiber composite luggage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com