Preparation method of high-dielectric and low-loss composite material with laminated structure

A composite material and lamination technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of reducing the capacitance and dielectric constant of laminated materials, and achieve strong applicability and practicability. The method is easy and the effect of increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present invention, the preparation method of composite material, specifically comprises the following steps:

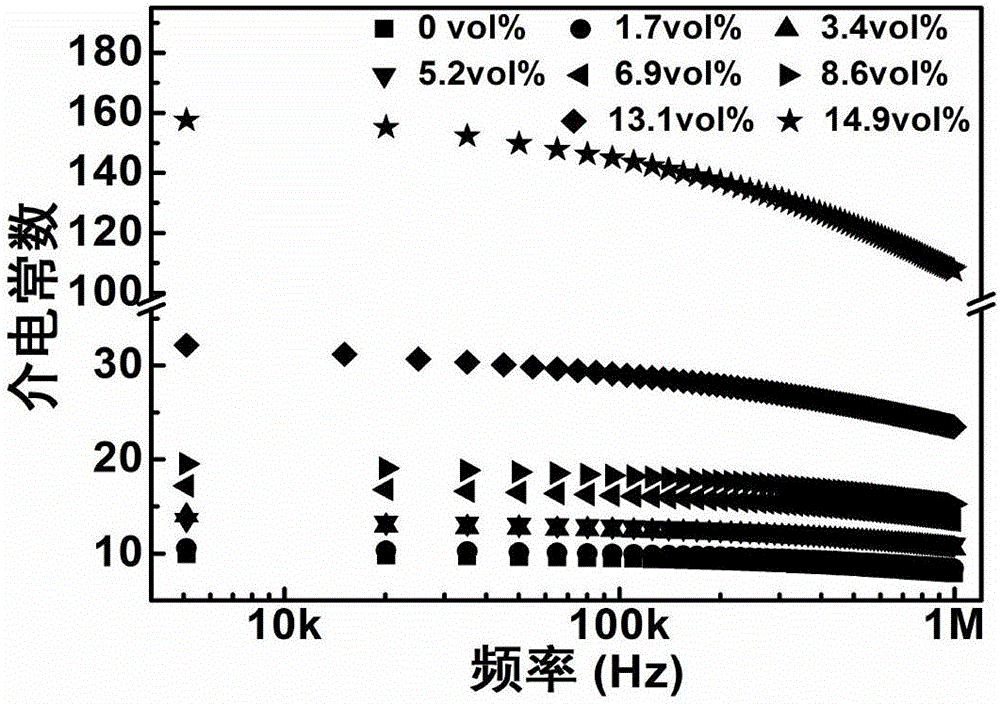

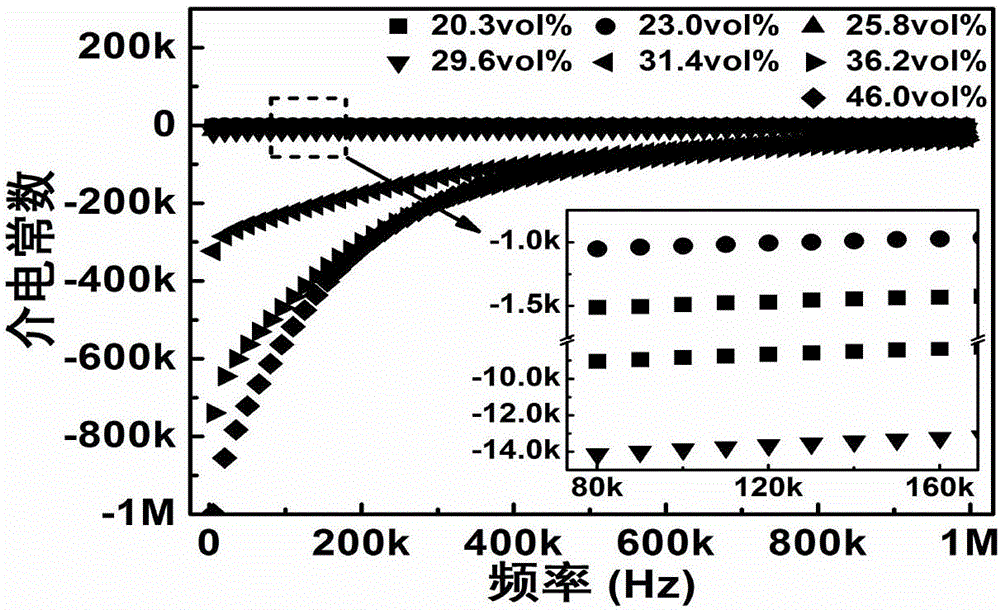

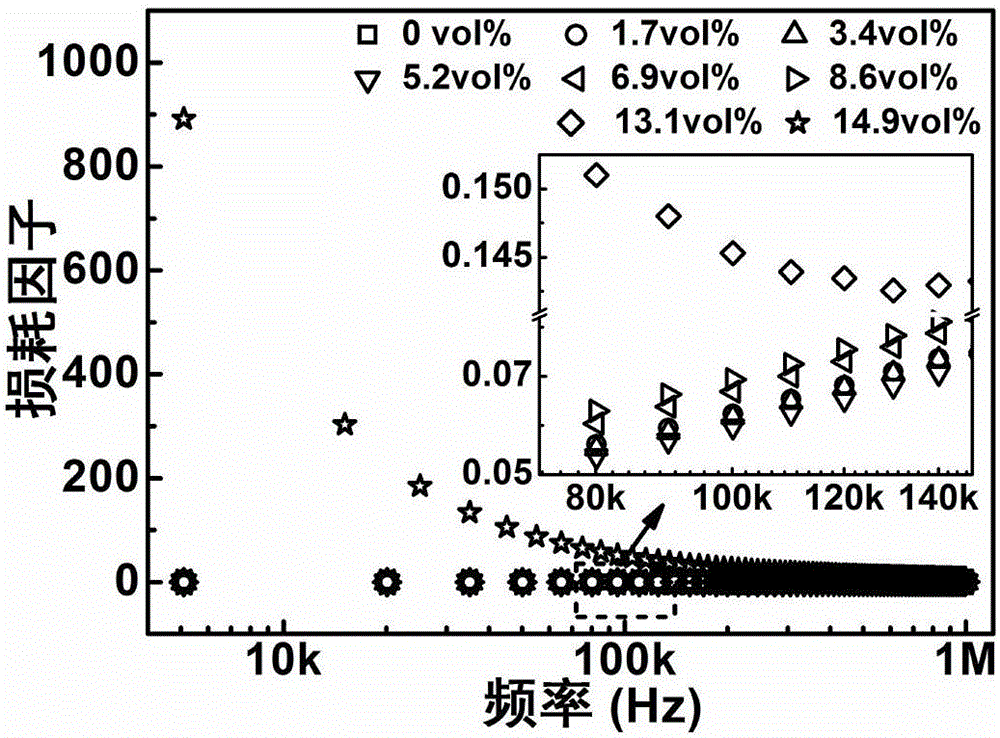

[0045](1) Mix PVDF powder and graphite powder in proportion, add absolute ethanol to ball mill for 30 minutes, fully dry at 70°C, and grind in a mortar for 10 minutes. In the mixed raw materials of PVDF powder and graphite powder, the volume fraction of graphite is respectively: 0vol %-46vol% (specific composition points are 0vol%, 1.7vol%, 3.4vol%, 5.2vol%, 6.9vol%, 8.6vol%, 13.1vol%, 14.9vol%, 20.3vol%, 23.0vol%, 25.8vol% %, 29.6vol%, 31.4vol%, 36.2vol%, 46.0vol%);

[0046] (2) Single-layer sample hot-press molding: pour the powder obtained in step (1) into the mold, apply a pressure of 5-10MPa to discharge the air and release the pressure, heat to a temperature of 184°C, press at a pressure of 10MPa for 5min, and maintain Under pressure conditions, after the mold is cooled to below the thermal deformation temperature of PVDF, a single-layer sample is ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com