Electro-hydraulic servo brake system with multi-working modes

An electro-hydraulic servo and brake system technology, applied in the direction of brake control system, brake, brake components, etc., can solve the problem that the dynamic performance of the motor cannot meet the multi-channel multiplexing method, the pressure adjustment target cannot be achieved, and the backup mechanism for failure Complicated structure and other issues to achieve good brake pedal feel, high reliability, and small fluctuations in system pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

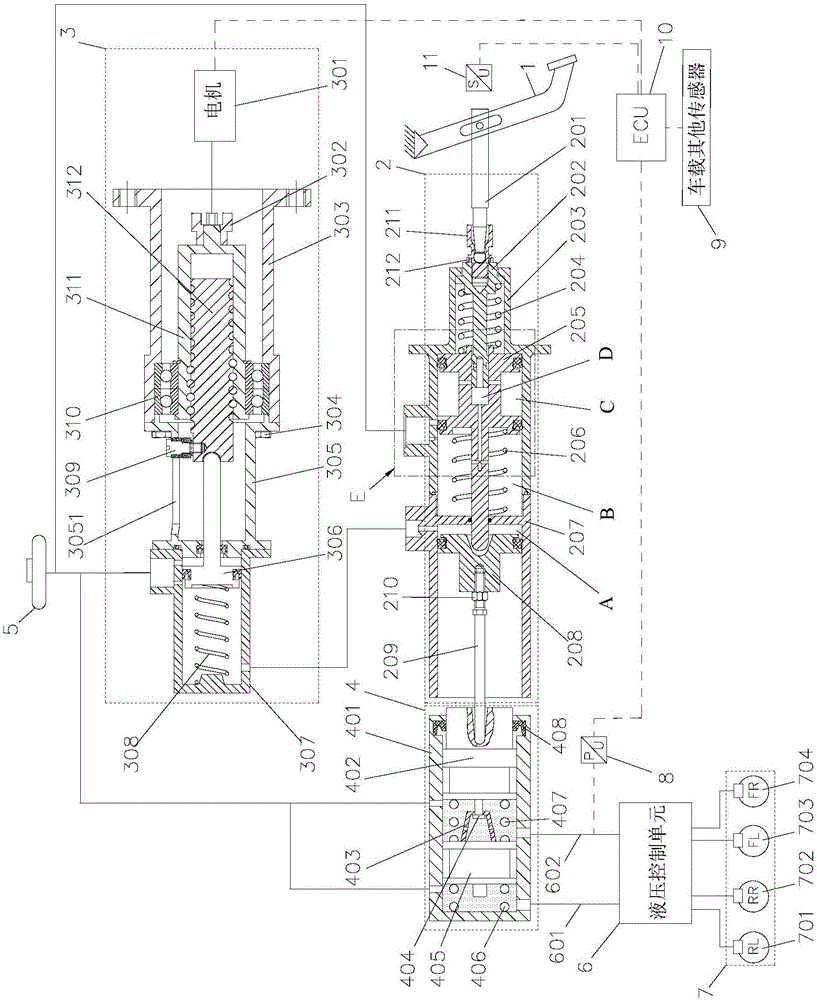

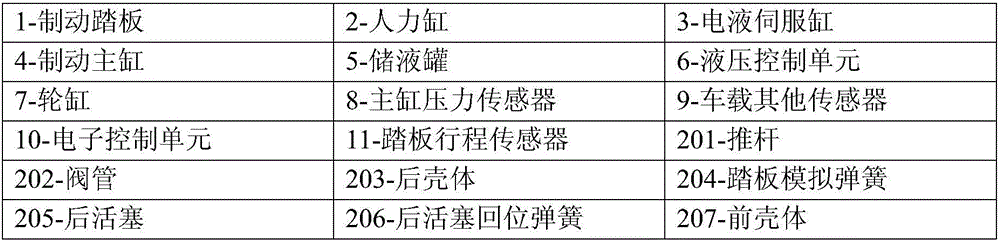

[0039] see figure 1 , the present invention is an electro-hydraulic servo braking system with multiple working modes, which includes a brake pedal 1, a manpower cylinder 2, an electro-hydraulic servo cylinder 3, a brake master cylinder 4, a liquid storage tank 5, and a hydraulic control unit 6. Wheel cylinder 7, master cylinder pressure sensor 8, electronic control unit 10, pedal travel sensor 11. The electronic control unit 10, that is, ECU (Electronic Control Unit), is also called "driving computer" or "vehicle computer".

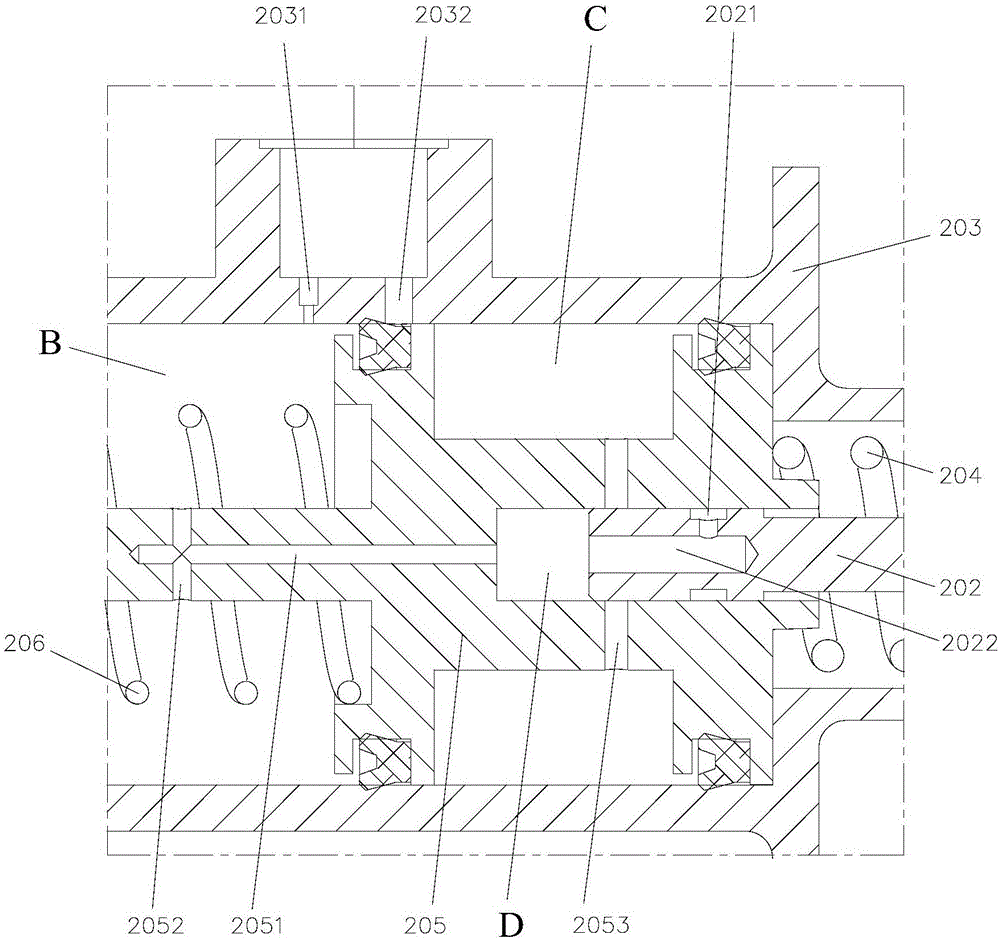

[0040] The human cylinder 2 includes a push rod 201, a clamp 211, a valve pipe 202, a rear housing 203, a pedal simulation spring 204, a rear piston 205, a rear piston return spring 206, a front housing 207, a front piston 208, and a push rod 209 , lock nut 210, clamp 211. Wherein, the valve tube 202 is located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com