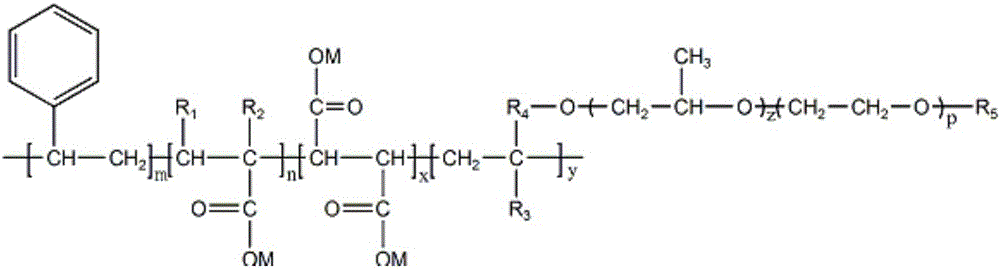

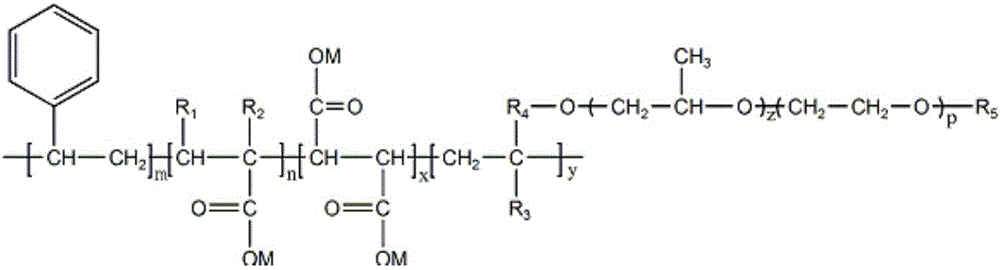

Novel modified polyether type dispersing agent and preparation method thereof

A polyether and dispersant technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problem that the hydrophilic group does not play a good role, the performance of the dispersant does not achieve the desired effect, and has not been widely used To achieve the effect of improving stability and compatibility, strong environmental adaptability and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a preparation method of a novel modified polyether dispersant, which consists of the following steps:

[0032] (1) Add appropriate amount of maleic anhydride and solvent in a multi-port reactor equipped with agitator, dropping funnel, thermometer and reflux condenser, at a temperature of 50°C, so that maleic anhydride can be completely dissolved in the solvent, and then Add 1 / 3 of the volume of the total initiator (AIBN solution, azobisisobutyronitrile solution) into the above system, the mass ratio of maleic anhydride to the total initiator is 0.5%, heat and stir and then raise the temperature to 80°C;

[0033] (2) Mix an appropriate amount of styrene, methacrylic acid and solvent evenly at room temperature, place it in the dropping funnel and slowly drop it into the system of the above step (1), and keep stirring, and the dropping time is controlled at 3h At the same time, an appropriate amount of chain transfer agent alkyl mercaptan, initia...

Embodiment 2

[0039] This embodiment relates to a preparation method of a novel modified polyether dispersant, which consists of the following steps:

[0040] (1) Add an appropriate amount of maleic anhydride and solvent into a three-necked flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, at a temperature of 55°C, so that the maleic anhydride can be completely dissolved in the solvent, and then the total trigger 1 / 4 of the volume of the agent (AIBN solution) was added to the above system, the mass ratio of maleic anhydride to the total initiator was 1.0%, and then the temperature was raised to 82°C;

[0041] (2) Mix an appropriate amount of styrene, acrylic acid monomer, and solvent evenly at room temperature, place it in the dropping funnel and slowly drop it into the system of the above step (1), and keep stirring, and the dropping time is controlled at 2h At the same time, an appropriate amount of chain transfer agent alkyl mercaptan, initiator AIBN, and ...

Embodiment 3

[0047] This embodiment relates to a preparation method of a novel modified polyether dispersant, which consists of the following steps:

[0048](1) Add an appropriate amount of maleic anhydride and solvent in a three-necked flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, at a temperature of 60°C, so that the maleic anhydride can be completely dissolved in the solvent, and then add the total initiator (AIBN solution) 1 / 3 of the volume was added to the above system, the mass ratio of maleic anhydride to the total initiator was 1.3%, and then the temperature was raised to 78°C;

[0049] (2) Mix an appropriate amount of styrene, methacrylic acid, crotonic acid, and solvent evenly at room temperature, place it in the dropping funnel and slowly drop it into the system of the above step (1), and keep stirring, dropwise The time is controlled at 3 hours, and at the same time, an appropriate amount of chain transfer agent alkyl mercaptan, AIBN and solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com